Title Page

-

Prepared by

-

Conducted on

-

Task

-

Location

-

Instructions:

Introduce yourself to the TM(s) and explain the Genie – ACE program.

Ask TM(s) one or more questions found below. Provide feedback below

Complete the observation looking for Life Saving Behaviors

Document (+/desired) behavior and (-/at risk) behaviors

Recognize TM(s) who are following the Life Saving Behaviors

Team Member Engagement Questions

-

What motivates you to work safely?

-

How could you get hurt from doing your job?

-

How could you do your job more safely?

-

When have you paused for safety in your area?

-

How can you improve safety in your area?

-

How do you protect yourself and others from hazards?

-

What are the hazards of the job you are doing?

-

Have you completed your daily inspection? (Hoist, PIT, Tool)

Life Saving Behaviors

-

Use the questions below to determine if a JOB PAUSE is needed

Work at Height Activity

-

-

If TM’s are working at height what controls are in place to prevent them from falling; conversely, do you see work at height (greater than 4 ft. or 1.2 m) that is not controlled?

-

Did you Pause The Job?

Lifting Activities

-

-

In production or routine lifts, look for the lift plan or lift SOP and verify the procedures. In the field or for non-standard lifts – ask for the rigging plan, which may be hand written with diagrams or a checklist

-

Did you Pause The Job?

Danger zone risks

-

-

Are TM’s standing free and clear of the danger zone from unstable or suspended load?

-

Did you Pause The Job?

Lock Out & Tag Out risks

-

-

If you observe a LOTO in progress ask the TM to walk you through how they identify when LOTO is required and the process they go through to ensure they have locked out and tagged all energy sources

-

Did you Pause the Job?

Machine Safety risks

-

-

If machinery is in use speak with the TM about the required interlocks and guards they check before operating equipment, are they functioning?

-

Did you Pause the Job

PIT risks

-

-

Observe fork lifts in use and look to see what actions TM’s take to work safely around vehicles. Do you have concerns?

-

Did you Pause the Job

Confined Spaces risks

-

-

Ask if they have confined spaces in their workspace and the checks they make before entry into the confined space, are they working safely?

-

Did you Pause the Job?

Seat Belt risks

-

-

Observe to see if seat belts are being worn when operating vehicles?

-

Did you Pause the Job?

-

-

Is there anything else you see that you believe should be paused and reviewed before proceeding?

-

Explain:

Discussion with TM

-

After the observation, spend a few minutes talking with the Team Member about the following: What can we (your leadership) do to make things safer and better? How they think it is best to reinforce the LSB’S?

General Conditions and Behaviors

PPE

-

For any UNSAFE actions, add which Tier board this item needs to be escalated to in the comments section

-

PPE Man Available and Correct?

-

Comments:

-

Safety Glasses Worn and Worn Correctly?

-

Comments:

-

Steel Toe Shoes Worn?

-

Comments:

-

Hearing Protection Worn and Worn Correctly?

-

Comments:

-

Proper Gloves Worn for Task?

-

Comments:

-

Weld PPE Worn and in Good Condition?

-

Comments:

-

Other Comments:

Positions of Team Members

-

Struck By (moving object)

-

Comments:

-

Struck Against (running into object)

-

Comments:

-

Pinch/Caught Hazard (body part between two parts)

-

Comments:

-

Fall Hazard ( working at > 4' with no fall protection)

-

Comments:

-

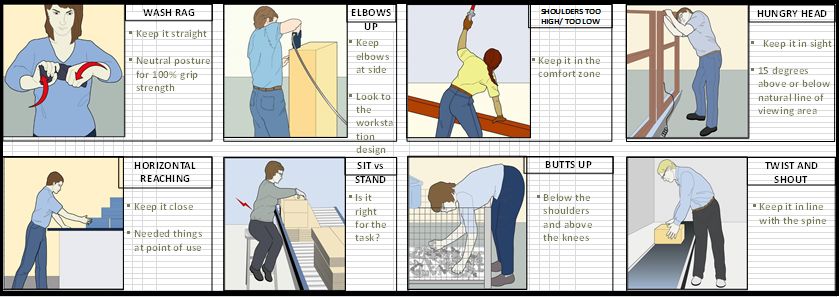

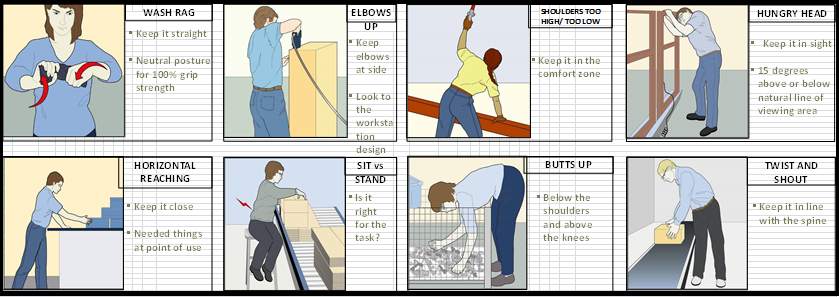

Ergonomic Considerations

-

Repetitive Motion (ergonomic concern)a

-

Comments:

-

Ergonomic Considerations

-

Awkward Position (ergonomic concern)

-

Comments:

-

Other comments:

Tools and Equipment

-

Tools in safe condition

-

Comments:

-

Tools used in safe manner

-

Comments:

-

Right tool for the job

-

Comments:

-

TM authorized to use tool

-

Comments:

-

Other comments:

Unsafe Conditions

-

Slip/Trip Hazards (hoses, liquids, raised guides)

-

Comments:

-

Machine guarding (in place, adequate)

-

Comments:

-

Cranes / Hoist (daily inspections, use properly)

-

Comments:

-

Carts (tip hazard, maintained, trip hazard)

-

Comments

-

Other Comments: