Audit / Inspection Details

-

Title of Worksite Inspection

-

Inspection by

-

Team Leader

-

Production activities

-

Date and time

-

Location inspected

Worksite Inspection

1. Maintenance (Comments and corrective actions)

-

No temporary repairs?

-

Smooth and clean surfaces for production area?

-

Validation of scales and metal detector completed?

-

If maintenance carried out, is a maintenance card used?

-

Any brittle material identified and, if so in good condition?

-

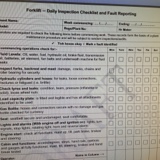

Forklifts clean and in good condition?

-

Has the pre-operational checklist been completed?

-

Other issues

Issue

-

Other issues

2. Pest control (Comments and corrective actions)

-

Walk around for pest inspection completed?

-

All chemicals used in pest control stored correctly as per safety data information?

-

Other issues?

Issue

-

Other issues

3. Cleaning and sanitation (Comments and corrective actions)

-

Brushes and other utensils used for cleaning / processing?

-

Food contact surfaces are controlled and clearly identified?

-

Chemicals stored and labelled correctly as required by safety data sheet (SDS)?

-

Cleaning equipment stored properly?

-

Other issues

Issue

-

Other issues

4. Identification and traceability (Comments and corrective actions)

-

Products and raw materials properly labelled?

-

Correct label used for production (Best before date)?

-

Only organic or non-organic products labelled in production area?

-

Other issues

Issue

-

Other issues

5. Manufacturing (Comments and corrective actions)

-

Correct information being recorded in run sheet?

-

Visual inspections completed in raw and finished product?

-

Foreign material being collected and monitored?

-

Correct forms being filled out properly?

-

Correct storage of products?

-

Other issues

Issue

-

Other issues

6. Hazard analysis and critical control point (HACCP) (Comments and corrective actions)

-

Raw material approved for production?

-

Samples being taken and properly identified?

-

Samples handled properly?

-

No hemp seed on floor?

-

Other issues

Issue

-

Other issues

7. Hygienic practices (Comments and corrective actions)

-

PPE used properly

-

Illness report completed if required?

-

Handwashing done properly?

-

Cleaning areas are clean?

-

Toilets are kept clean?

-

No food being eaten in production area?

-

Other issues

Issue

-

Other issues

Inspected by (Name, comments and signature)

-

Comments and overall rating

-

Name and signature of person conducting inspection

-

Name and signature of production supervisor