Information

-

Document No.

-

Audit Title

-

Client / Site

-

Conducted on

-

Prepared by

-

Location

-

Personnel

Job Number

-

Job Number

Work Description

-

Describe the work being carried out.

Equipment

-

Equipment being worked on

Licence Number

-

Electricians Licence Number

Administrative Procedures

-

Have obtained permits (Excavation, Hot Works, Confined Space etc)

-

Site Induction for workers current

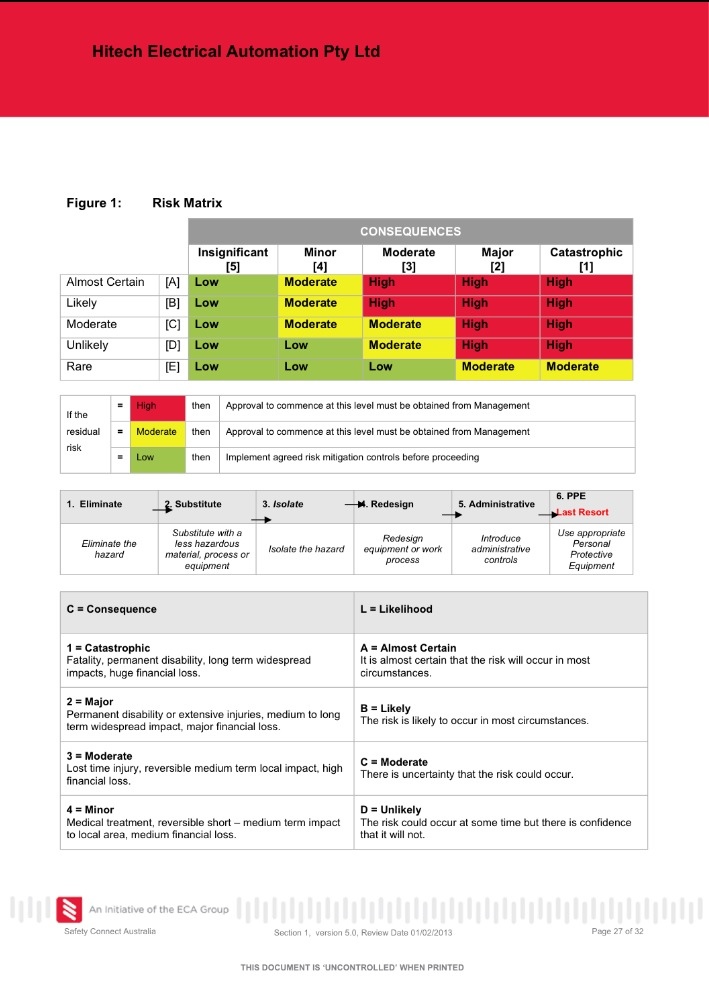

Note - All risk scores are determined using ECA Safety Connect Risk Matrix

-

-

Attach Risk Matrix

Work Method Statements

-

WMS - 100 - Live Electrical Fault Finding and Testing

-

WMS - 101 - Electrical Fault Finding and Testing in MCC’s, Control boxes and Junction Boxes

-

WMS - 102 - Electrical Fault Finding, Testing, Repairs and Replacement in the Field

-

WMS - 103 - Resetting Drives, Soft Starters and Overloads in MCC

-

WMS - 104 - Isolations – General

-

WMS - 105 - Test & Tagging of electrical appliances & leads

-

WMS - 106 - Working at Heights

-

WMS - 107 - Working in Areas with Mobile Plant Operating

-

WMS - 108 - Replacing/ Repairing Parts in MCC’s, Control Boxes and Junction Boxes

-

WMS - 109 - Replacing/ Repairing Lights

-

WMS - 110 - Replacing/ Testing Motors

-

WMS - 111 - Working in a Trench or Pit at a depth of 1.5M or more

-

WMS - 112 - Replacing Testing Motors in Melawondi Kilns

-

WMS - 113 - Using Jig Saws

-

WMS - 114 - Using Electric Drills

-

WMS - 115 - Using Reciprocating Saws

-

WMS - 116 - Using Angle Grinders

-

WMS - 117 - Using Cut Off Saws

-

WMS - 121 - Exposure to UV Radiation

Personal Protective Equipment (PPE)

-

Adequate PPE (including sun protection)

-

Adequate training in safe use, clean-up and inspection of PPE?

Electrical Hazards

-

Is the equipment electrically energised?

-

High fault level

-

Induced voltages

-

UPS or back up power supplies

-

Restricted access

-

Multiple power sources - multiple circuits

-

Does anything have to be isolated and tested for dead?

-

Does the work have to be carried out live? NB - live work form must be completed and signed by QTP.

Manual Handling

-

Can I strain or overexert myself?

-

Do I need lifting equipment?

Mobile and Fixed Equipment

-

Can I be injured by being caught in, on or between anything?

-

Can I fall into or onto anything?

-

Can I slip or trip on anything?

-

Can I be struck by a moving object or mobile plant?

-

Can I be injured by nearby activities or can my activities injure others nearby?

-

Can something fall onto me or can I cause something to fall onto someone else?

Working at Heights

-

Fall risks of 2m or more? (including voids, pits, and trenches)

-

Lack of edge protection?

-

Unsafe or incomplete edge protection?

Harness and Equipment

-

Unsafe or damaged harness or equipment?

-

Incompatible hooks/equipment?

-

Unsafe or uncertified anchor points?

-

Lack of or inadequate formal training?

Ladders

-

Unsafe or damaged ladders?

-

Unsafe positioning of ladders?

-

Ladder not properly secured?

-

Ladder unsuitable for job? (e.g. metal ladder used for electrical work)

-

Insufficient, or incorrect, PPE?

-

Unsuitable storage containers? (unlabeled or stored in food containers)

Work Environment

-

Insufficient lighting?

-

Inadequate housekeeping?

-

Lack of, or inadequate noise/ vibration control?

-

Can I come into contact with or be exposed to something that may harm me? (heat, gas, hazardous substances or stored energy)

Environmental Hazards

-

Lack of/or inadequate, dust suppression system?

-

Is the atmosphere clear from flammable gases, toxic gases, dust, vapours/ fumes, steam or other?

-

Lack of/or inadequate systems to prevent contaminants entering stormwater drains?

Control Prompts In Use

-

Competent person - all electricians are licenced

-

Remove any obstacles to provide a clear path

-

Wear appropriate PPE

-

Test for dead/ prove isolation

-

Place barricading around area

-

Wear insulated gloves

-

Check for dangers, live terminals etc

-

Use lock out tags and procedures

-

Visually inspect

-

Clean work area

-

Inspect ladder before use

-

Above 1.8m maintain 3 points of contact

-

Tie off and foot ladder

-

Use correct PPE on EWP

-

Lifting- use two people or lifting device

-

Be carefully around slippery areas

-

Let people around you know about your work

-

Ensure no pinch points

-

Ensure trench is under 1.5 m

-

Wear high vis clothing

-

Use of sun cream, hats etc

-

Use correct tools

-

Inspect gear before use

-

Check for sharp edges

-

Competent and in date assistant and LVR kit

-

Test/fault finding equipment is category 3 or4

-

Beware of mobile plant and where able make radio contact

-

Further control measures put in place to manage hazards.

-

Risk Score before control measures

-

Risk Score after control measures

Other Corrective Actions

-

Enter any corrective actions that will be undertaken

Drawings

-

Any drawings or sketches that apply to the job

-

Any pictures that apply to the job

-

Text

Sign Off

-

Risk Assessment Filled Out By

-

Electrical Worker In Charge

-

Electrical Worker

-

Electrical Worker

-

Electrical Worker

-

Electrical Worker

-

Electrical Worker

-

Electrical Worker

-

Site Manager or Supervisor/ Representative if Available