Information

IAEC CREW INSPECTION

-

REC Name

-

REC contact person

-

Conducted on

-

Prepared by

-

Location of inspection (individual report per location)

CREW MEMBERS

Person In Charge

TEAM Member names

OPERATING PROCEDURE MODIFICATIONS

-

Are there any Operating Procedures different from the IAEC Operating Procedures being practiced

DESCRIPTION OF WORK BEING PERFORMED

STARTING THE JOB

-

Employee in charge on site

-

Documented Tailgate - hazards, special precautions, energy source controls, PPE required and employee fitness

-

Any alternative energy sources to be aware of (wind, solar, etc.)

-

Tailgate kept in standard location at job site (foreman truck, on cone by truck etc.)

-

Adequate number of crew for the job

-

Proper rated FR clothing available

-

Conductive articles (jewelry) removed when working energized equipment

-

One call notified

-

Horseplay noticed

-

Weather conditions

-

Terrain conditions in work area

-

Member permission sought when working on private property

CONDUCTOR WORK (includes energized, de energized and de energized and grounded work)

-

Qualified Employee doing work

-

Cover-up used

-

Used proper amount of cover-up

-

Gloves and sleeves (if applicable) worn cradle to cradle, lock to lock and ground to ground

-

Proper class of glove worn

-

Protectors in good condition

-

Proper class of sleeve worn

-

Proper rated FR clothing worn

-

Observer watching

-

Proper disconnection of energized equipment

-

Good practices during switching of circuits

-

Proper LOTO practices

-

One person in charge of clearance

-

Tested for absence of voltage prior to grounding

-

Conductor cleaned before applying ground

-

Ground clamps in good condition

-

Grounds installed with live line tool

-

Grounded properly (ground connection first to make last to break?)

-

Running grounds used

-

If multiple crews - proper communication used

-

Add media

AERIAL DEVICES

-

Boom clean

-

Pre-flight of controls

-

Controls marked

-

Wheels chocked

-

Outrigger pads used

-

Proper fall protection worn

-

Trucks grounded

-

Correct amount of fiberglass out when needed

-

Co workers rubber gloves located outside of truck for possible bucket rescue

-

Used approved device and method when lifting equipment (OH transformers, material, OCR's etc.)

-

Load being lifted was within rated capacity of equipment

-

Proper hand signals/communication occurred between operator and crew when maneuvering load

-

Maintained positive control of load

-

Best Practice suggestions

-

Add media

NEUTRALS

-

Bridged before opening

-

Proper communication used

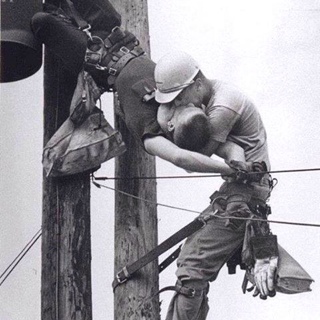

CLIMBING

-

Employee certified as climber

-

Inspected tools before climbing

-

Sharps on hooks guarded

-

Long sleeve shirt worn while climbing

-

Hand line used

-

Co workers climbing gear out of truck and ready if needed for pole top rescue?

-

Best practice suggestions

-

Add media

POLES

-

Hauled properly (Including flag and/or light at end of pole?)

-

Proper Gloves worn while handling (rubber gloves when applicable)

-

Proper cover-up when setting pole near an energized system

-

Used pole puller to remove pole(s) being being replaced

-

Pole tongs used

-

Crew avoided being underneath suspended loads

-

Crew maneuvered load to avoid getting caught between objects

-

Proper hand signals/communication occurred between operator and crew when maneuvering load

-

Maintained positive control of load

-

Add media

EQUIPMENT AND TRAILERS

-

Current registration (trailers, ATV's etc)

-

Current DOT inspection - trailer(s)

-

Select date

-

Current Fire Extinguisher inspection date

-

Select date

-

Safety devices and features in good operating condition

-

Wheel chocks used when applicable

-

Seat belt worn while operating equipment

-

Adequate number of tie downs used

-

Adequate rated tie down used for load securement

-

Add media

MISC EQUIPMENT (Other CMV's or equipment such as backhoes, dozers, forklifts, skidsteers etc.)

-

Type of equipment

-

Add media

-

Current DOT inspection

-

Current registration

-

Current Fire Extinguisher inspection date

-

Select date

-

Safety devices and features in good operating condition

-

Wheel chocks used when applicable

-

Seat belt worn while operating equipment

-

Add media

VEHICLES

-

Daily inspection completed

-

Current insurance and accident information in vehicle

-

Current inspection date of First Aid, Fire Extinguisher and BBP kit

-

Select date

-

Select date

-

Select date

-

AED battery life indicator good

-

Seat belts worn while in transit

-

Interior/exterior well kept

-

Adequate Cargo Securement practices

-

Adequate tire inflation and tread depth

-

Back up alarms working

-

Current dielectric test

-

Select date

-

Current DOT annual inspection

-

Select date

-

Add media

TRAFFIC CONTROL

-

High visiblility vests worn

-

Signs used in accordance to traffic control rules and regs

-

Proper size signs

-

Cones used in accordance with traffic control rules and regs

-

Proper size cones

-

Minimum 5 cones used as promoted by IAEC Safety

-

Flagger used when needed

-

Proper flagging equipment

-

Flagging done properly

-

Four way flashers used

-

Strobe/Rotating light in use

-

Best practice suggestions

-

Add media

URD WORK

-

Competent person on job site

-

Adequate trench protection

-

Means of egress in trench

-

Spoils 2ft from trench

-

Cables spiked before cutting

-

Compliant signage on cabinets (warning/danger)

-

Cabinets locked with dual locking system (penta bolt and padlock)

-

Used approved device and method when lifting URD equipment (transformers, switchgear, peds etc.)

-

Load being lifted was within rated capacity of equipment

-

Crew avoided being underneath suspended loads

-

Crew maneuvered load to avoid getting caught between objects

-

Proper hand signals/communication occurred between operator and crew when maneuvering load

-

Maintained positive control of load

-

Add media

TREE TRIMMING

-

Proper PPE worn (chaps, hearing, eye/face and head protection etc.)

-

Safe operation of chainsaw took place (Started safely/used chain break etc.)

-

Chainsaw fueled 10' or more from work zone

-

Chainsaw safety features operable

-

PPE used during chemical application

-

Sprayers labeled properly

-

Co workers in safe work zone from chainsaw operator

-

Rubber gloves worn when needed

-

Employee tied in when in tree

-

Cables in good condition

-

Best practice suggestions

-

Add media

SUBSTATIONS

-

Qualified employee for level of work being performed

-

Proper PPE worn

-

Observer watching

-

Substation gate properly secured during work process

-

Substation is compliant with applicable regulations

-

Best practice suggestion

-

Add media

ROPES, SLINGS, STRAPS, HOISTS, CHAINS

-

Strap hoists compliant

-

Chain hoists compliant

-

Ropes in good condition (including hand lines and rope locks)

-

Slings compliant

-

Chains compliant

-

Add media

TOOLS

-

Battery, electric, hydraulic and hand tools stored properly

-

Cords in good condition

-

Hydraulic hoses/connectors in good condition

-

Sharps guarded when not in use

-

Correct tool used for the job

-

Proper PPE worn with tool being used

-

Tool safety devices in place and working

-

Avoided pinch points while operating tools

-

Add media

HOT STICKS

-

Proper length

-

Clean and free of moisture?

-

Stored properly

-

Add media

LIVE LINE TOOLS, JUMPERS AND GROUND TEST DATES

-

Live line tool test date compliant

-

Select date

-

Jumpers/Macs test date compliant

-

Select date

-

Grounds test date compliant

-

Select date

-

Hot arm test date

-

Select date

PROTECTIVE WEAR - HEAD, EYE, FACE AND HEARING

-

Compliant Z89 Class E hard hat

-

Clean

-

Compliant Z87 eyewear

-

Side shields

-

Head and eye protection worn

-

Approved face shield worn (if required per arc flash study)

-

Decibel reading from smart phone app

-

Hearing protection worn

RUBBER GOODS TEST DATES

-

Rubber gloves test date compliant

-

Select date

-

Rubber sleeves test date compliant

-

Select date

-

Cover up compliant test date (rubber hoses/guts, blankets, hard cover up)

-

Select date

SUMMARY, COMMENTS AND PICTURES

-

Add media

-

Add media

TEAM MEMBER SIGNATURES - confirms crew inspection detail has been discussed with you

-

Add signature

-

Status

-

Add signature

-

Status

- Journeyman

- Apprentice

- Groundman

- Equipment Operator

- Other

-

Add signature

-

Status

- Journeyman

- Apprentice

- Groundman

- Equipment Operator

- Other

-

Add signature

-

Status

- Journeyman

- Apprentice

- Groundman

- Equipment Operator

- Other

-

Add signature

-

Status

- Journeyman

- Apprentice

- Groundman

- Equipment Operator

- Other

-

Add signature

-

Status

- Journeyman

- Apprentice

- Groundman

- Equipment Operator

- Other

-

Add signature

-

Status

- Journeyman

- Apprentice

- Groundman

- Equipment Operator

- Other

-

Add signature

-

Status

- Journeyman

- Apprentice

- Groundman

- Equipment Operator

- Other

IEAC SAFETY PERSONNEL SIGNATURES

John Dvorak

-

Add signature

Matt Pociask

-

Add signature

Sam Yarham

-

Add signature