Title Page

-

Site conducted

-

Operator Name

-

Which Ipad Are You Using?

-

Shift

-

Date & Time

-

-

Need safety gear? ask your supervisor!

-

Take Photos of Leaks and Make Sure To Add In The Red Book

Mezzanine

Hot Water Pump #2

-

Status

-

Suction

-

Discharge

Supply Temperature

Hot Water Pump #1

-

Status

-

Suction

-

Discharge

Supply Temperature

Medium Chilled Water Pump #1

-

Status

-

Suction

-

Discharge

Medium Chilled Water Pump #2

-

Status

-

Suction

-

Discharge

Medium Chilled Water Heat Exchange #1

-

Chilled Water PSI In

-

Chilled Water PSI Out

Chilled Water Temperature In

Chilled Water Temperature Out

-

Medium Chilled Water PSI In

-

Medium Chilled Water PSI Out

Medium Chilled Water Temperature In

Medium Chilled Water Temperature Out

Medium Chilled Water Heat Exchange #2

-

Chilled Water PSI In

-

Chilled Water PSI Out

Chilled Water Temperature In

Chilled Water Temperature Out

-

Medium Chilled Water PSI In

-

Medium Chilled Water PSI Out

Medium Chilled Water Temperature In

Medium Chilled Water Temperature Out

Humidifier HF-01-01 ( Services AH#2)

-

Steam draining?

-

Steam Condensate PSI

AHU #2 **UNIT IS CRITICAL**

-

Status

-

Alarm

-

Time of Alarm

-

Cause of Alarm

-

Was Unit Able to Be Returend to Normal Operation

-

Call Controls or Foreman

Basement

Lab Air Compressor

Power EX Control Panel

-

Alarm

-

Dryer #1

-

Dryer #2

-

Which dryer is running?

-

PSI Gauge - Measures Air is Reserve Tank

Dryer #1 & #2

-

Dryer Gauge #1

-

Dryer Gauge #2

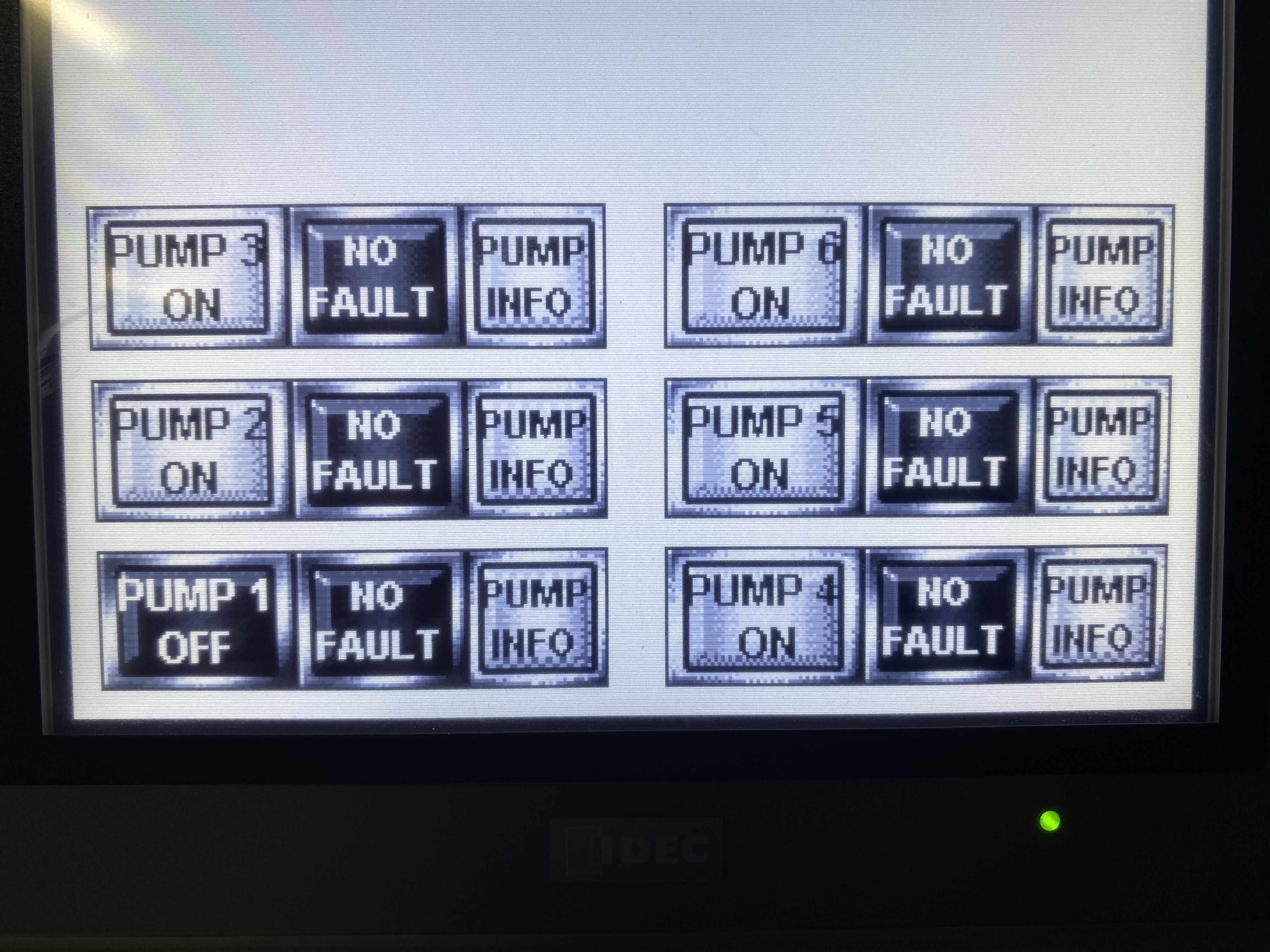

LCD Screen

-

Alarm

-

Status

-

PSI

-

Look at pump number order

-

Pump #3

-

Pump #2

-

Pump #1

-

Pump #6

-

Pump #5

-

Pump #4

Air Tech Vacuum Pump

-

LCD Screen

-

Alarms

Vacuum Reading

-

Tank mmHg

-

LCD Screen Reading

Pump #1

-

Status

-

% Percentage Running

-

Hours running

Pump #2

-

Status

-

% Percentage Running

-

Hours running

Pump #3

-

Status

-

% Percentage Running

-

Hours running

Condenser Water Return Pump (Red light on top vfd)

-

Alarm

-

Water Level

House Pumps Domestic

-

Alarms

-

PSI In

-

PSI Out

RO Water

-

Alarms

-

Alarm Type

RO Tank

-

1850 gallons is max full - 600 is low water

-

Is The Tank Below 600 gallons

-

How Many RO Pumps Turned On

-

Did Pump 3 & 4 Turn Off - VFD should read 0

-

Water Level

Control Panel (Right Side)

-

VFD : RO Pump labeled 1&2 / also number 3&4. Please Refer to the VFD using Rop#1 & ROP#2

-

Repress Pump Select

-

Pump P - 3

-

Pump P - 4

Control Panel (Left Side- LCD Screen)

-

RO 1

-

TAKE PHOTO OF SIGHT GLASS x3 & THE 2 PRESSURE GAUGES

-

RO 2

-

TAKE PHOTO OF SIGHT GLASS x3 & THE 2 PRESSURE GAUGES

-

Conductivity = Units of milliSiemens/cm (mS/cm)

-

RO Conductivity

-

Permeate Level

-

15 gpm Minimum 20 is Maximum

-

Loop Flow (gpm)

VFD Screen Status - Bottom Right Corner Screen

-

P3

-

P4

Condenser Water Pump #1

-

Status

-

Suction

-

Discharge

Condenser Water Pump #2

-

Status

-

Suction

-

Discharge

Condenser Water Pump #3

-

Status

-

Suction

-

Discharge

AHU #1

-

Status

-

Alarm

-

Time of Alarm

-

Cause of Alarm

-

Was Unit Able to Be Returend to Normal Operation

-

Call Controls or Foreman

Heat Recovery Chiller

-

Alarms

-

What Was The Alarm Type

-

Was The Chiller Able To Be Returned To Normal Operation

-

Was Alarm Cleared / Reset

-

Did Another Chiller Turn On

-

Can You Start Another Unit

-

Did You follow The After Hours Incident Chart

-

Multi- Stack

-

HRC Chilled Water Pump #2

-

Chilled Water PSI In

-

Chilled Water PSI Out

Chilled Water Temperature In

Chilled Water Temperature Out

-

HRC Heating Hot Water Pump #1

-

Hot Water PSI In

-

Hot Water Psi Out

Hot Water Temperature In

Hot Water Temperature Out

Chiller #1 TRANE

-

Alarms

-

What Was The Alarm Type

-

Was The Chiller Able To Be Returned To Normal Operation

-

Was Alarm Cleared / Reset

-

Did Another Chiller Turn On

-

Can You Start Another Unit

-

Did You follow The After Hours Incident Chart

-

Status

-

Run Time

-

Starts

-

Amperage

Oil Sump Temperature

-

Oil Level

-

Oil Press Gauge

-

Evaporator Press Gauge

-

Condenser Water Gauge

-

Purge - Pump Out Life

-

Condenser Water Press In

-

Condenser Water Press Out

Condenser Water Temperature In

Condenser Water Temperature Out

-

Chilled Water Press In

-

Chilled Water Press Out

Chilled Water Temperature In

Chilled Water Temperature Out

-

Limit Demand Setting

Chiller #2 TRANE

-

Alarms

-

What Was The Alarm Type

-

Was The Chiller Able To Be Returned To Normal Operation

-

Was Alarm Cleared / Reset

-

Did Another Chiller Turn On

-

Can You Start Another Unit

-

Did You follow The After Hours Incident Chart

-

Status

-

Run Time

-

Starts

-

Amperage

Oil Sump Temperature

-

Oil Level

-

Oil Press Gauge

-

Evaporator Press Gauge

-

Condenser Water Gauge

-

Purge - Pump Out Life

-

Condenser Water Press In

-

Condenser Water Press Out

Condenser Water Temperature In

Condenser Water Temperature Out

-

Chilled Water Press In

-

Chilled Water Press Out

Chilled Water Temperature In

Chilled Water Temperature Out

-

Limit Demand Setting

Primary Chilled Water Pump #1

-

Status

-

Suction

-

Discharge

Primary Chilled Water Pump #2

-

Status

-

Suction

-

Discharge

Chilled Water Pump #1

-

Status

-

Suction

-

Discharge

Chilled Water Pump #2

-

Status

-

Suction

-

Discharge

Chilled Water Pump #3

-

Status

-

Suction

-

Discharge

Condenser Unit Return

-

Visual Inspection

Penthouse

Heat Trace

-

Alarms

Domestic Water Heaters #1-4

-

Status

Temperature

AHU #8

-

Alarm

-

Time of Alarm

-

Cause of Alarm

-

Was Unit Able to Be Returned to Normal Operation

-

Call Controls or Foreman

-

Status

AHU #7

-

Alarm

-

Time of Alarm

-

Cause of Alarm

-

Was Unit Able to Be Returned to Normal Operation

-

Call Controls or Foreman

-

Status

AHU #6

-

Status

-

Alarm

-

Time of Alarm

-

Cause of Alarm

-

Was Unit Able to Be Returned to Normal Operation

-

Call Controls or Foreman

Lab Exhaust Fan 1A

-

Status

Lab Exhaust Fan 1B

-

Status

Lab Exhaust Fan 1C

-

Status

Lab Exhaust Fan 1D

-

Status

AHU #5

-

Alarm

-

Time of Alarm

-

Cause of Alarm

-

Was Unit Able to Be Returned to Normal Operation

-

Call Controls or Foreman

-

Status

Lab Exhaust Fan 2A

-

Status

Lab Exhaust Fan 2B

-

Status

Kitchen Exhaust Fan

-

Status

AHU #4

-

Alarm

-

Time of Alarm

-

Cause of Alarm

-

Was Unit Able to Be Returned to Normal Operation

-

Call Controls or Foreman

-

Status

AHU #3

-

Alarm

-

Time of Alarm

-

Cause of Alarm

-

Was Unit Able to Be Returned to Normal Operation

-

Call Controls or Foreman

-

Status

Boilers

DA Gauges

-

Temperature

-

Water PSI

-

Steam PSI

Steam Boiler *Control Panel*

-

Boiler #1

-

Boiler #2

-

Alarms

Pump Selection * Control Panel*

-

Pump Number Selected On

-

Pump #1 Status

-

Switch Control

-

Are boilers being serviced?

-

Pump #2 Status

-

Switch Control

-

Are boilers being serviced?

Boiler #1

-

Alarms

-

Time of Alarm

-

Alarm Type

Supply Temperature Before Resetting Alarm

Return Temperature Before Resetting Alarm

-

Was Unit Able To Return Back To Normal

-

Did You Contact Foreman or Mechanic

-

Status

-

PSI

-

Sight Glass

Boiler #2

-

Alarms

-

Time of Alarm

-

Alarm Type

Supply Temperature Before Resetting Alarm

Return Temperature Before Resetting Alarm

-

Was Unit Able To Return Back To Normal

-

Did You Contact Foreman or Mechanic

-

Status

-

PSI

-

Sight Glass

Deaerator

-

Water Level

-

Contact Foreman or Mechanic

-

Is there an increased amount of water going to drain

Roof

Cooling Towers

Cooling Tower #1

-

Status

Cooling Tower #2

-

Status