Title Page

-

Site conducted

-

Operator Name

-

Which Ipad Are You Using?

-

Date & Time

-

Shift

-

-

Need safety gear? ask your supervisor!

-

Take Photos of Leaks and Make Sure To Add In The Red Book

Rooftop Exhaust Fan - East to West

Rooftop

Autoclave Exhaust East Side

-

Status

Barrier Exhaust Fans #1-5 Red Stacks

Equipment Information

-

-

Exhaust Fan #1 Must be on

-

These exhaust fans are in 2 groups. 2 & 3 are paired and 4 & 5 are paired together. 1 of the fans from each group must be on.

Barrier Exhaust #1 - Stand Alone

-

Status

Barrier Exhaust #2

-

Status

Barrier Exhaust #3

-

Status

Barrier Exhaust #4

-

Status

Barrier Exhaust #5

-

Status

Lab Exhaust 1-4 Left to Right

Lab Exhaust #1

-

Status

Lab Exhaust #2

-

Status

Lab Exhaust #3

-

Status

Lab Exhaust #4

-

Status

Bathroom Exhaust West Side

-

Status

AHU#7 Room

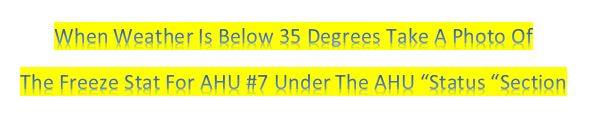

Cold Weather - AHU Freeze Stat Check

-

35°F & Colder Follow These Instructions

AHU #7

-

AHU #7 MUST BE ON AT ALL TIMES

-

Alarm

-

Time of Alarm

-

Cause of Alarm

-

Was Unit Able to Be Returned to Normal Operation

-

Call Controls or Foreman

-

Status

-

Steam PSI Supply To Room

-

Steam PSI Supply To AHU#7

-

Filters

-

VFD

-

Was VFD Able to Be Returned To Auto

-

Notify Controls

AHU #7 Pre-Cool

-

Chilled Water Supply PSI

-

Chilled Water Supply Temperature

-

Chilled Water Return PSI

-

Chilled Water Return Temperature

AHU #7 Chilled Water

-

Chilled Water Supply PSI

-

Chilled Water Supply Temperature

-

Chilled Water Return PSI

-

Chilled Water Return Temperature

Chilled Water Pump

-

Which Pump Is On

-

Chilled Water Supply To Pump

-

Chilled Water PSI Supply To AHU #7

Basement East - West

Air Compressor #1 & #2

Equipment Information

-

Air Compressor serves the cage washers

-

Normal PSI Range should be 100-150PSI

-

It should be concerning if the compressor is running and not ever cycling off

Ingersoll Air Compressor #1

-

Compressor Controls

-

Is The Air Compressor Running?

-

Air Tank Pressure

Ingersoll Air Compressor #2

-

Compressor Controls

-

Is The Air Compressor Running?

-

Air Tank Pressure

Water Meter

-

Flow Meter

R.O SYSTEM

DI Pump #1 & #2

-

Pump Running

-

Pressure Pump Outlet

WATER TANK

-

Tank Level

AHU #6

-

MUST BE ON AT ALL TIMES

-

Alarm

-

Time of Alarm

-

Cause of Alarm

-

Was Unit Able to Be Returned to Normal Operation

-

Call Controls or Foreman

-

Status

AHU #6A

-

MUST BE ON AT ALL TIMES

-

Alarm

-

Time of Alarm

-

Cause of Alarm

-

Was Unit Able to Be Returned to Normal Operation

-

Call Controls or Foreman

-

Status

AHU #5

-

Status

-

Alarm

-

Time of Alarm

-

Cause of Alarm

-

Was Unit Able to Be Returned to Normal Operation

-

Call Controls or Foreman

-

VFD

-

Was VFD Able to Be Returned To Auto

-

Notify Controls

AHU #4

-

Alarm

-

Time of Alarm

-

Cause of Alarm

-

Was Unit Able to Be Returned to Normal Operation

-

Call Controls or Foreman

-

Status

-

VFD

-

Was VFD Able to Be Returned To Auto

-

Notify Controls

Chilled Water Pump #16

-

Status

-

Suction

-

Discharge

Vacuum Pump

Vacuum Pump

-

Alarm

-

Alarm Type

-

Pump #1

-

mmHg

-

Pump hours

-

Pump load %

-

Pump #2

-

mmHg

-

Pump Hours

-

Pump load %

AHU #3

-

Alarm

-

Time of Alarm

-

Cause of Alarm

-

Was Unit Able to Be Returned to Normal Operation

-

Call Controls or Foreman

-

Status

-

VFD

-

Was VFD Able to Be Returned To Auto

-

Notify Controls

Chilled Water Pump #15

-

Status

-

Suction

-

Discharge

Chilled Water Pump #5

-

Status

-

Suction

-

Discharge

Chilled Water Pump #4

-

Status

-

Suction

-

Discharge

AHU #2

-

Alarm

-

Time of Alarm

-

Cause of Alarm

-

Was Unit Able to Be Returned to Normal Operation

-

Call Controls or Foreman

-

Status

-

VFD

-

Was VFD Able to Be Returned To Auto

-

Notify Controls

AHU #1

-

Alarm

-

Time of Alarm

-

Cause of Alarm

-

Was Unit Able to Be Returned to Normal Operation

-

Call Controls or Foreman

-

Status

-

VFD

-

Was VFD Able to Be Returned To Auto

-

Notify Controls

Chilled Water Pump #21

-

Status

-

Suction

-

Discharge

Hot Water Pump #18

-

Status

-

Suction

-

Discharge

Condenser Water Pump #4

-

Status

-

Suction

-

Discharge

Hot Water Pump #17

-

Status

-

Suction

-

Discharge

Condenser Water Pump #5

-

Status

-

Suction

-

Discharge

Chiller #4 TRANE

Alarms

-

Alarms

-

What Was The Alarm Type

-

Was The Chiller Able To Be Returned To Normal Operation

-

Was Alarm Cleared / Reset

-

Did Another Chiller Turn On

-

Can You Start Another Unit

-

Did You follow The After Hours Incident Chart

Operation Status

-

Status

-

Outside Air Temperature

Compressor

-

Compressor Run Time

-

Compressor Starts

Oil Tank Temperature

-

Oil Pump Discharge Pressure

-

Oil Tank Pressure

-

Contact Foreman

Evaporator Page

-

Active Chilled Water Setpoint

Evaporator Leaving Water Temperature

Evaporator Entering Water Temperature

-

Evap Rfgt Pressure

-

Contact Foreman

Evaporator approach temperature

Condenser Page

-

Condenser Entering Water Temperature

Condenser Leaving Water Temperature

-

Condenser Refrigerant Pressure

-

Contact Foreman

Condenser approach temp

Motor Page

-

Active Current Limit Set Point

-

Contact Foreman

-

Average Motor Current Percent % RLA

Purge Page

-

Purge - Pump Out Life

Physical Gauge on Pipe

-

Chilled water Supply Pressure

-

Chilled water Return Pressure

-

Condenser Supply Pressure

-

Condenser Return Pressure

Side of Chiller Near Oil Filter

-

Oil Level

Chiller #5 TRANE

Alarms

-

Alarms

-

What Was The Alarm Type

-

Was The Chiller Able To Be Returned To Normal Operation

-

Was Alarm Cleared / Reset

-

Did Another Chiller Turn On

-

Can You Start Another Unit

-

Did You follow The After Hours Incident Chart

Operation Status

-

Status

-

Outside Air Temperature

Compressor

-

Compressor Run Time

-

Compressor Starts

Oil Tank Temperature

-

Oil Pump Discharge Pressure

-

Oil Tank Pressure

-

Contact Foreman

Evaporator Page

-

Active Chilled Water Setpoint

Evaporator Leaving Water Temperature

Evaporator Entering Water Temperature

-

Evap Rfgt Pressure

-

Contact Foreman

Evaporator approach temperature

Condenser Page

-

Condenser Entering Water Temperature

Condenser Leaving Water Temperature

-

Condenser Refrigerant Pressure

-

Contact Foreman

Condenser approach temp

Motor Page

-

Active Current Limit Set Point

-

Contact Foreman

-

Average Motor Current Percent % RLA

Purge Page

-

Purge - Pump Out Life

Physical Gauge on Pipe

-

Chilled water Supply Pressure

-

Chilled water Return Pressure

-

Condenser Supply Pressure

-

Condenser Return Pressure

Side of Chiller Near Oil Filter

-

Oil Level

Steam Boilers

Steam Boilers 1 & 2

-

One Of The Boilers Must Be On

Boiler Feed Tank Temperature

-

Gauge Located on the back of Feed Tank

-

Contact Forman & Mechanic ASAP

-

Contact Foreman or Mechanic

Boiler #2 Hurst

-

Alarms

-

Panel

-

Time of Alarm

-

Alarm Type

Supply Temperature Before Resetting Alarm

Return Temperature Before Resetting Alarm

-

Was Unit Able To Return Back To Normal

-

Did You Contact Mechanic / Controls

-

Status

-

Sight Glass

-

Leaks

-

PSI

Boiler #1 Kewanee

-

Alarms

-

Time of Alarm

-

Alarm Type

Supply Temperature Before Resetting Alarm

Return Temperature Before Resetting Alarm

-

Was Unit Able To Return Back To Normal

-

Did You Contact Mechanic / Controls

-

Status

-

Sight Glass

-

Leaks

-

PSI