Title Page

-

Job Number

-

Client

-

Job Address

-

Job Description

-

Conducted on

-

Prepared by

-

Personnel

ARCP

Asbestos Removal Control Plan

-

What classification is the asbestos being removed?

- Friable

- Non-Friable (Bonded)

-

What type of asbestos material is being removed?

- Roofing

- Internal Linings

- External cladding or soffits

- Flooring

-

What method will be used to remove the material?

-

Wet Method

Prior to removal asbestos, all material will be sprayed down with a mixture of water and binding agent. This mixture will prevent the release of asbestos fibres during the removal.

All nails/screws and timber trim will be removed to allow access to asbestos materials. Asbestos materials will be removed in full sheets to avoid any unnecessary breakage.

All timber framing and cavities behind the asbestos material will be cleared of debris and vacuumed with HEPA filtered vacuums.

Once a clearance has been issued, all removal areas and remaining framing will be sprayed with PVA. -

Black plastic lined bellow and around all removal areas where required to prevent contamination.

-

What specific tools and PPE will be used?

- P2 Mask

- Coveralls

- Disposable Gloves

- HEPA filtered vacuums

- Hammer, chisel & nail pullers

- Pressure spray bottle

-

How will the asbestos material be transported from site and disposed?

-

Tipper will be double lined with black plastic and sealed when job is complete. All asbestos waste will be transported to an EPA registered facility by a licensed driver.

-

Skip bin will be double lined with black plastic and sealed once the job is complete. The skip company will be notified asap to remove the waste from site.

-

Are there any additional risks? What control measures will be put in place to manage these risks?

Signed by all removalists on site

-

Licensed Asbestos Removalist

-

Licensed Asbestos Removalist

-

Licensed Asbestos Removalist

-

Licensed Asbestos Removalist

-

Licensed Asbestos Removalist

-

Licensed Asbestos Removalist

-

Licensed Asbestos Removalist

-

Licensed Asbestos Removalist

-

Licensed Asbestos Removalist

SWMS

Company Details

-

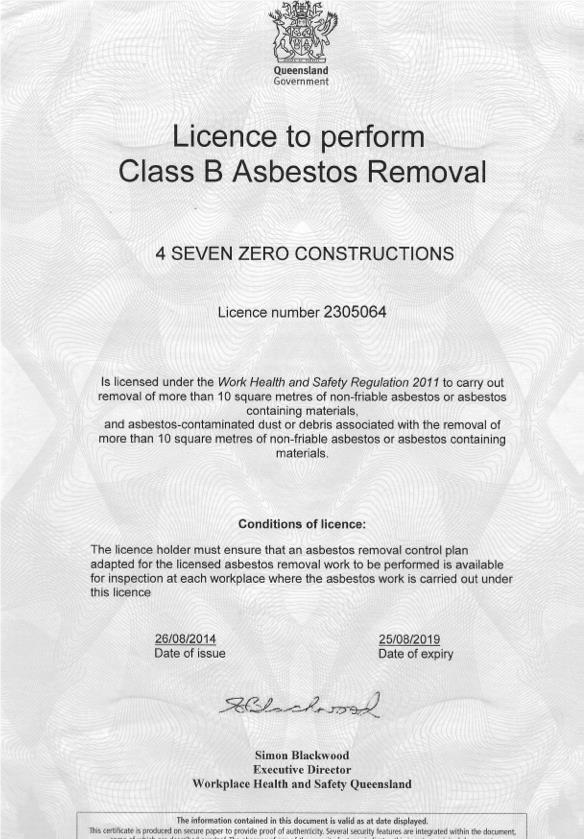

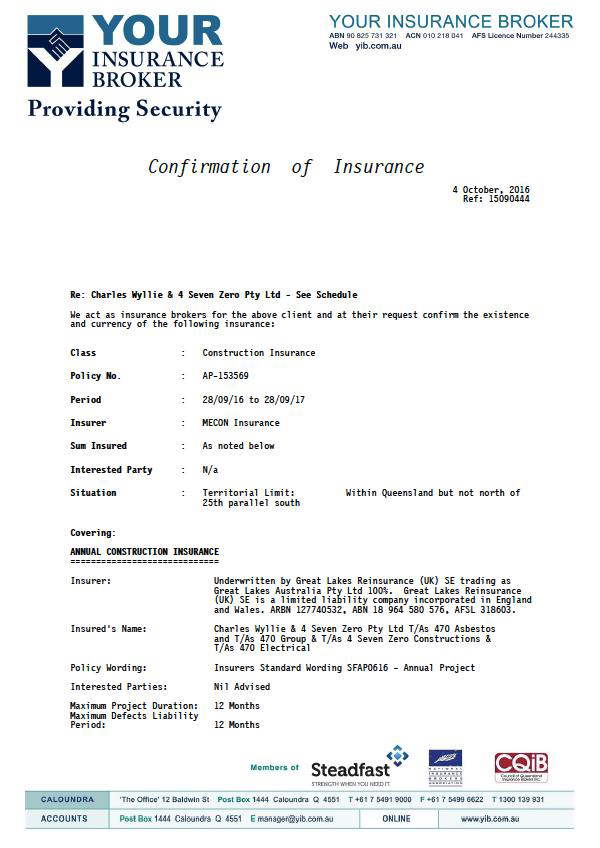

Company Name: 4 Seven Zero Pty Ltd

ABN: 36601119546

Asbestos License#: 2305064

Address: PO Box 114 Mooloolaba

Contact: Charles Wyllie, Managing Director, 0411556152

Project Details

-

Job Address

-

Job Number

-

Job Description

-

Project Supervisor on Site

Personal Protective Equipment

-

Site Specific P.P.E. Requirements: Safety footwear, high visibility shirt or vest, hard hat and sun protection if required (broad brim hat, sun screen, tinted safety glasses), eye protection (goggles), face protection, hand protection (gloves).

As Required: hearing protection, breathing protection (P2), overalls.

Hydration: hearing All staff are expected to be well hydrated on arrival to site and have adequate water onsite. Where Hot weather is forecast, additional breaks will be taken and iced water and supplementation provided as required.

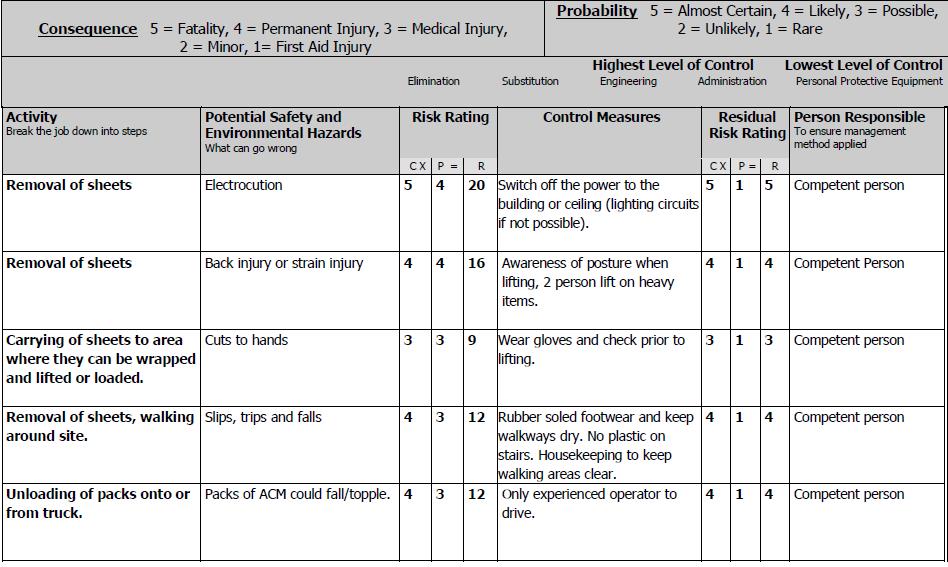

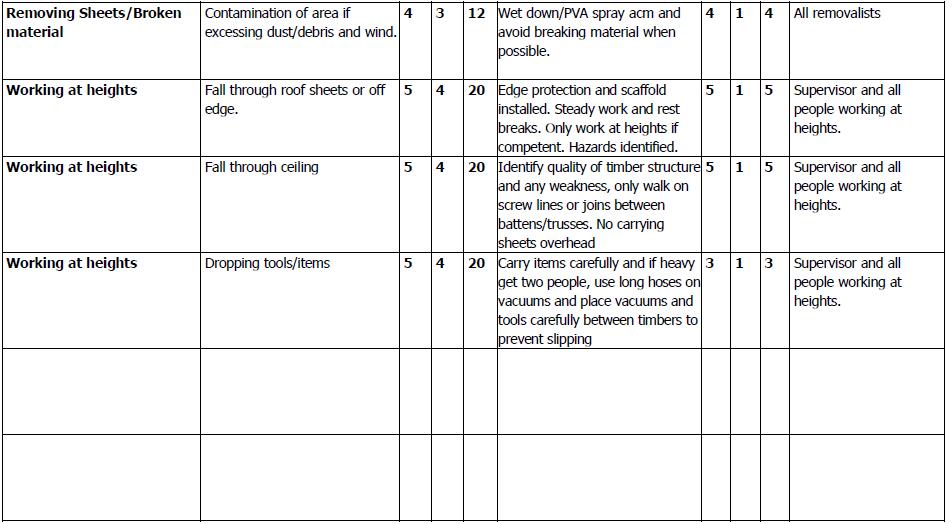

Job Safety Analysis

Safety Notes

-

All asbestos removal will be as per Qld COP and QWHS standards. All waste tracking certificates will be supplied to Client/Builder on request. In the event a fault or any deviation to work method statement occurs employees are to stop works, perform a JSA and communicate to workforce via a tool box meeting. Copies of the SWMS and ARCP will be provided to the Client/Builder on request.

Emergency Plan

-

Account for all staff and exit site to street and clear from site. Call 000.

Induction Commitment Statement / Employee Signoff

-

Induction commitment statement

We the undersigned workers acknowledge that we hold a current construction safety induction card and any undermentioned current Non-Friable Asbestos licenses. We have been issued with Personal Protective Equipment and have been instructed in its use. We are familiar with and understand the contents of this Work Method Statement and agree to work responsibly. We understand Non-Friable asbestos removal Codes of Practice and Safe Work Methods that must be employed in the removal process. We acknowledge that non-conformance with the contents of Safe Work Methods, Code of Practice or Legislation. We agree to work responsibly and acknowledge that non-compliance with the above will result in termination of employment and possible personal liability for punitive fines incurred by the Employer/Principal Contractor.

I have read the above SWMS and I understand its contents. I confirm that I have the skills and training, including relevant certification to conduct the task as described. I agree to comply with safety requirements within this Asbestos Removal Control Plan, SWMS including safe work instructions and Personal Protective Equipment described. -

Supervisor On Site

-

Licensed Asbestos Removalist

-

Licensed Asbestos Removalist

-

Licensed Asbestos Removalist

-

Licensed Asbestos Removalist

-

Licensed Asbestos Removalist

-

Licensed Asbestos Removalist

-

Licensed Asbestos Removalist

-

Licensed Asbestos Removalist

Visitors Induction Commitment Statement

-

I the undersigned confirm and declare that I have received a site induction and that I have been briefed in the standard Asbestos Removal Control Plan. I agree to abide by its content. I agree to wear PPE and follow any direction by the Principal Contractor or his representative. I absolve the Principal Contractor from any liability relating to any incident occurring to me. I hold the Principal Contractor indemnified for any cost resulting from actions. I acknowledge that non-compliance with the above may result in my removal from site.

-

Add signature

-

Add signature

-

Add signature

-

This SWMS has been developed in consultation with and approved by:

Charles Wyllie

Managing Director

Signed 01/01/2017 -

-

Job Report

Prior to Start Date

-

Have all equipment, tools and materials needed to carry out the job been prepared prior to start?

-

What was not organised?

-

Have all relevant site contacts been provided to you. Including contact details for the client (Builder/ Primary Contractor), owner/tenant, other trades and hygienist.

-

Is the project scope clear?

-

What information was not provided to you by the project manager that was required to complete the job?

-

Has the the project manager organised and provided everything required to complete the job.

-

What was not organised?

Job in Progress

-

All staff on site have been signed onto the SWMS & ARCP.

-

Before Photos of Project

-

Exclusion zones have been established with

-

What areas of the property are at risk of being damaged that may result in a call back.

- Timber Flooring

- Air Conditioners or vents

- Fabric items such as carpet or clothing

- Gutters

- Furniture

-

What are the control measures put in place to prevent defects in these areas?

-

Has floor protection been installed sufficiently to prevent any damage occurring? <br>At the very least this includes 3mm MDF to prevent scratching and dents.

Job Completion

-

Quality of decontamination has been inspected. Multiple removalists conducted emu pick around the perimeter of house or removal area to clean debris. All nails, screws and glue have been removed from the timber frame. Timber frame and removal area have been thoroughly vacuumed with HEPA filtered vacuums. At time of completion, no asbestos dust or debris is present.

-

Clearance Certificate has been provided by the hygienist or competent person

-

Relevant parties have been informed of completion: Primary contractor, Site Manager, owner/tenant, other trades etc. Other trades have been allowed back on site.

-

Photos of Job Completion

-

Site has been inspected for damage.

-

Has any damage occurred during the job?

-

What has occurred?

-

Photos of damage

-

What action is needed to rectify the damage?

-

What date will asbestos waste be transported and disposed of at waste facility?

Incident Report

-

Were there any accidents, injuries/illnesses or incidents (including near misses) during the project?

-

What happened?

-

Date / Time of Incident

-

Who was affected?

-

Location within site

-

Cause(s) - How did the incident occur?

-

Injuries - Detail any injuries sustained

-

Treatment - Provide details of any emergency or other action which was taken (include details of any hospital treatment including name of hospital, diagnosis, medication provided)

-

Machinery/Vehicles - Identify any machinery or vehicles involves Detail any damage that occurred

-

Signed by supervisor on site