Title Page

-

Department

-

Type of Lock Out:

-

Date:

-

Lock Out Done by:

-

Sinagture

-

Process/ Task/ Machine:

-

undefined

COMPLIANCE ACHIEVED

-

1. Is the Lock out procedure available and understood by staff?

-

1.1. Verify by asking questions

-

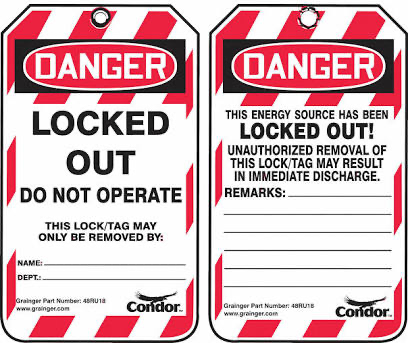

2. Are "Lock Out" tags and locks and/or "Out of Service" tags in use?

-

3. Are "Lock Out" tags and locks and/or "Out of Service" tags filled out correctly?

-

4. Are spare “Lock Out” tags and “Out of Service” tags readily available?

-

5. Do all employees use “Lock Out” tags and “Out of Service” tags correctly?

-

6. Are lock out locks, scissors and tags being used for all isolations?

-

7. Are all isolation devices labelled?

-

8. Are keys removed from the lock out locks whilst personnel are working on the equipment?

-

9. Is there a copy of the "Lockout/Tagout Quick Reference Guide" available on site? ( One Plan Lesson)

-

10. Are all personnel and operators who is required to lock out, trained?

-

11. Are all machinery or equipment capable of movement, required to be de-energized or disengaged and locked-out during <br> cleaning, servicing, adjusting or setting up operations, whenever required? (CAN IT BE LOCKED OUT? place to attach locks,etc.)

-

12. Does the lockout procedure require that stored energy (mechanical, hydraulic, air, etc.) be released or blocked before equipment <br> is locked-out for repairs?

-

13. Are employees required to keep personal control of their key(s) while they have safety locks in use?

-

13.1 Is a register available and up to date?

-

14. Is it required that only the employee exposed to the hazard, place or remove the safety lock?

-

15. Is it required that employees check the safety of the lock-out by attempting a startup after making sure no one is exposed?

-

16. Are employees instructed to always push the E - stop button immediately after checking the safety of the lock-out?

-

17. Are there a means provided to identify any or all employees who are working on locked-out equipment by their <br> locks or accompanying tags?

-

18. Are a sufficient number of accident preventive signs or tags and safety padlocks provided for any reasonably <br> foreseeable repair emergency?

-

19. When machine operations, configuration or size requires the operator to leave his or her control station to install <br> tools or perform other operations, and that part of the machine could move if accidentally activated. Is such <br> element required to be separately locked or blocked out?

-

20. In the event that equipment or lines cannot be shut down, locked-out and tagged, is a safe job the procedure <br> established and rigidly followed?

-

21. Are all staff wearing correct PPE?

Sigantories

-

Action Required:

-

By Whom:

-

Target Date:

-

Auditee

-

Auditor