Title Page

-

Name of Area:

-

Conducted on

-

Lab/Area Room and office room:

-

Gas cylinder room:

General Safety

-

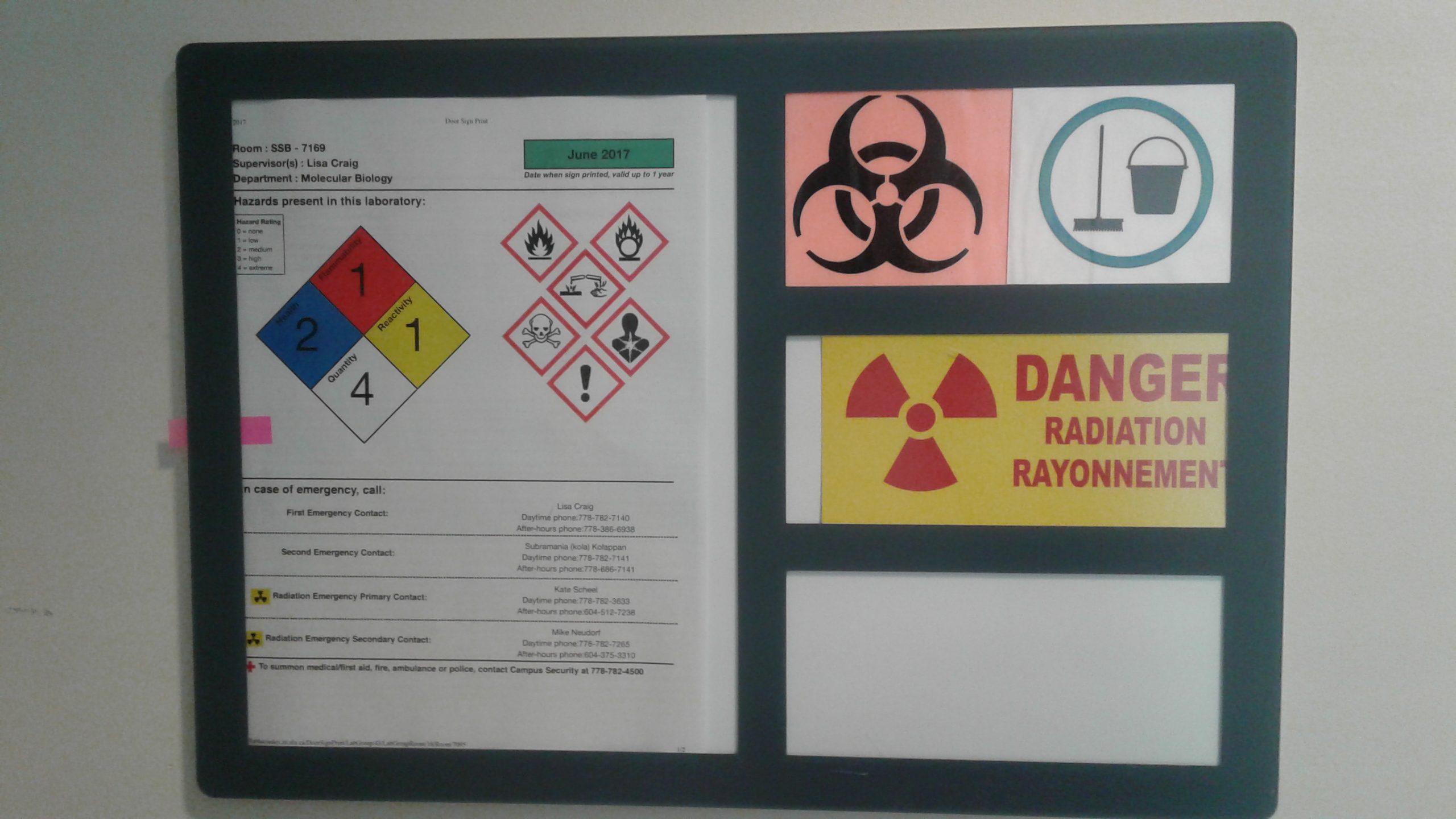

Are up-to-date Chemical hazard signs posted on doors leading to rooms with hazardous chemicals (need to be updated annually)?

-

If biohazards or radioactive materials (including naturally occurring) are used, are required permits in place (need to be posted at the lab door)?

-

No food or drink present in lab space

-

Is any other appropriate additional safety signage posted where necessary? (e.g. X-ray, laser rooms)

-

Is a monthly safety self-inspection checklist posted and completed?

-

Are safety inspection records kept and maintained?

-

Is the SFU Laboratory Safety manual and the SFU Hazardous Chemical Storage Manual available? (Do people know where to find it?)

-

Are personnel aware of who the safety committee members are in their area?

-

Are incident report forms being submitted for each incident?

-

Has the occupant or staff nearby reported/identified any recent water leaks or other items that require maintenance?

-

Does your lab have a checklist on the door to go through if you are the last one in the lab? E.g. walk through lab, check that machinery, heat sources, and gases are turned off, turn off water taps, etc.

Training

-

Have all personnel attended the relevant EHS lab safety training sessions? Is it documented? <br> EHS Laboratory Safety Training<br> EHS Safety Essentials <br>

-

Operators have received training on safe use of machinery or tools. Training is documented

-

Are procedures and equipment posing potential hazards identified, and have safe work procedures been developed to mitigate the hazards?

Emergency & Fire

-

Are campus emergency numbers posted by the phone?

-

Is there a first aid kit, and if so, a mechanism to track its use and keep it stocked?

-

Have the personnel been trained on how to use a chemical spill kit? And is it appropriately stocked? (Should include absorbent material, sealable plastic bas, PPE, etc.)

-

Have the safety showers and eyewash stations been inspected and tested monthly?

-

Are emergency safety showers and eyewash stations available, and are the areas around them unobstructed?

-

Are personnel familiar with the emergency evacuation plan, including egress routes, pull stations, extinguisher locations and assembly points?

-

Are emergency exit signs functional (i.e., not burnt out)?

-

Has the fire extinguisher been inspected within the last year?

-

Is the fire extinguisher accessible and the seal intact?

-

Do sprinkler heads have a minimum clearance of 18 inches? (no storage less than 18 inches directly under sprinkler head)

Personal Protective Equipment (PPE)

-

When working with hazardous materials, are lab coats available and worn when working in lab and stored separately from personal clothing, jackets, backpacks etc?

-

Are safety glasses/goggles and face shields available and worn when working with hazards such as caustics, corrosives, UV radiation, cryogenic liquids, infectious materials, glass, lasers, machine tools, etc.?

-

Are appropriate protective gloves available and worn when skin contact is a risk?

-

Is fully enclosed footwear worn inside the lab?

-

Are respirators being used? If yes, are they being stored properly? Are the respirator fit test records available?

Housekeeping

-

Are all aisles and doorways clear of materials and equipment?

-

Are office/work areas kept separate from laboratory areas?

-

Are fridges, benches and sinks reasonably clean and uncluttered?

-

Are supplies and materials stored properly on shelves i.e. heavier material stored on lower shelves?

-

Are racks and shelving properly installed and in good condition? **Before inspection day: Check brackets supporting shelves for signs of rust or breakage.**

Chemical Storage and Handling Safety

-

Is a hazardous materials inventory maintained? (State date of last inventory update.)

-

Are you aware of all the 'high hazard' chemicals in your lab, and are they in the chemical inventory?

-

Are SDSs available, up-to-date and accessible for all chemicals in use? (can have either available online or printed paper copies that must be updated every 3 years)

-

Are all chemical containers legibly labeled for contents and hazard (WHMIS)?

-

Is secondary containment used when storing hazardous liquid chemicals in refrigerators, freezers and cabinets? (plastic trays)

-

Are chemicals stored according to compatibility (oxidizers separated from flammables)?

-

Are flammable materials stored in closed containers and in approved flammable storage cabinets or refrigerators?

-

Are amounts of flammables and corrosives stored kept to a minimum?

-

Are flammable liquids heated safely with proper equipment? (e.g. not using an oil bath, or not directly on a hot plate in a beaker. Steam baths, salt, and sand baths, beads baths, heating mantles, and hot air are preferable.)

-

Are peroxide-forming compounds (e.g. ethers, isopropanol) labelled and dated when opened and not stored in direct sunlight?

-

Have peroxide-forming compounds been tested every 3-6 months for peroxide formation as per SFU protocols?

-

Are safe transportation procedures and equipment used for chemicals where necessary? (e.g. chemical carriers)

-

Do personnel know how to request disposal for hazardous materials? Have hazardous wastes produced in an area been identified, appropriately packaged and controlled?

-

Are separate waste receptacles for chemicals, sharps, glass, biohazards, and radioactive materials available and used?

-

Are waste containers filled only 75%, labeled for contents/hazards, and capped?

-

Are expired chemicals, after being reviewed by the supervisor, disposed of?

Machinery Safety

-

Jewelry: Not worn while operating machinery or tools

-

Lockout/Tagout: Used for service adjustment and maintenance of machinery

-

Machines must be attached to the floor or work surface

-

Hair: Tied back or otherwise secured

-

Clothing: No loose cuffs, gloves, neckties, drawstrings, etc. while operating machinery with rotating parts

-

Band saw – Ensure blade is guarded. Only the blade at point of operation should be exposed. Drive pulleys and belts covered.

-

Drill press – Drive belts & pulleys enclosed. Guard for bit and chuck. Spring loaded chuck key.

-

Lathes – Drive belts & pulleys enclosed. Guard chuck and use spring-loaded keys. Guards provided to protect operators from chips and cutting oils. Lead screw guarded to prevent entanglement of hair or clothing. Easily accessible stop switch

-

Sanders – Unused portion of belts & discs enclosed. Nip points at roller/belt interface enclosed. Sanding belts replaced when they become worn.

-

Power shears – Point of operation guarded. Foot treadle enclosed

-

CNC machines – Machine fully enclosed with interlocking doors. Polycarbonate panels are in good condition. Lockout tagout procedure for service or maintenance.

-

Grinders - Only the point of operation of the grinding wheel is exposed (25%) the remainder is enclosed. Tool rest positioned within 1/8-inch of the wheel, tongue guard positioned within 1/4-inch of the wheel. Wheels ring tested prior to use. Speed rating of wheel matches grinder.

-

Pneumatic nailers/staplers –Equipped with device that only allows operation when pressed against work surface.

-

Compressed air for cleaning – Limited to 30psi. Safety cleaning nozzles used.

-

Mechanical Power Transmission Equipment - All belts and pulleys enclosed.

-

Fans – When within seven feet of the floor, fan blades must be enclosed with no openings greater than 1/2-inch

-

Chain saws – Proper PPE including eye protection, mesh face shield, hearing protection, hard hat chaps, safety toe boots. Functional saw chain brake. Sharpened blade. Spark arrestor on exhaust.

-

Power Take Offs (PTO) – Ensure master guards and drive shaft guards in place

-

Hydraulics - Any hydraulically operated parts that could cause injury if the hydraulics fail or controls activate must have safety support bars that physically lock the hydraulic cylinders in the open position

Electrical Safety

-

Hazardous Energy Isolation - Machines that require service or adjustment must be provided with a means to be locked out while the work is performed

-

Are power bars used appropriately: <br>- One power bar can be directly plugged into a wall outlet or through a single extension cord into an outlet. It is not ok to plug one power bar into another power bar (no daisy chaining) <br>- power bars cannot be plugged into extension cords<br>- 12 outlet power bars must not be used<br>- Not used as a substitute for permanent wiring.<br>- Extension cords and power bars are not excessively loaded

-

Are cord guards used when electrical cords pass through walls, doors, ceilings, or across floors? (otherwise not acceptable)

-

Are all wires and plugs on equipment in lab in good condition? Grounding - Ensure machines and tools are double insulated or properly grounded. Grounding 3-prongs on cords

-

Are cables and cords secured to prevent a tripping hazard?

-

Are all panels and covers in place on electrical equipment?

-

Does electrical equipment have appropriate safety labeling present? (e.g., CSA certification)

-

Are there no acids or flammables in close contact with electrical ignition sources?

-

Machines & equipment directly connected to a receptacle, not a power bar

-

Anti-Restart Switch - machines that could injure the operator upon unexpected restart after a power interruption must be equipped with a reset switch that prevents unexpected starting.

-

Clearance of 36 inches maintained in front of electrical equipment requiring service

-

Power control for the machine must be easily accessible from the operator’s work position

-

Labeling – ensure all breakers and disconnects are labeled indicating machinery and equipment operated by the circuit

-

Light bulbs located within eight feet of the floor are protected by a cage or other means to prevent breakage

Vacuum Pumps and Compressed Gases

-

Are vacuum pumps installed and used appropriately? <br> Are exhausted to the outside (e.g., through the fume hood) <br> Oil-lubricated pumps are equipped with an oil mist filter<br> Used with cold trap(s) and/or other appropriate inlet trap to prevent contaminants from getting into pump oil and exhaust <br> Oil is regularly inspected for signs of contamination and changed when needed<br> Used with a tray underneath the vacuum pump to catch oil leaks <br> Does not have any oil leaks/spills

-

Do moving parts have guards installed (e.g. belt-drive vacuum pumps)?

-

Do vacuum pumps have cold traps to prevent volatile substances from getting into pump oil, or do they have a provision to purge pump?

-

Are compressed gas cylinders appropriately secured to a wall or bench with two points of contact with two chains, properly capped or regulated, stored upright (especially corrosive gases), and kept away from doors and electrical outlets?

-

Is a hand cart available for moving gas cylinders? The cart must have at least 4 wheels.

-

Are Dewar flasks and vacuum desiccators taped or guarded? Look for any rusty dewars.

-

Are all plastic and rubber tubes and hoses in good condition, with connections secured with wire or clamps to prevent accidental releases of hazardous materials?

-

Are any mercury thermometers still in use in the lab? If yes, contact EHS for disposal and replace it with the mercury-free alternative.

-

If an internal combustion engine is present, is maintenance and ventilation of the room verified and documented?

Additional Comments

-

Have the deficiencies from previous safety inspections been addressed?

-

Any additional comments?