Information

-

Conducted on

-

Location

WEEKLY ACCIDENT REVIEW

-

The week of May 13th we reported two new injuries.

The first injury happened in the SoCal division. A sheet metal apprentice was installing duct when he reached for his drill and brushed his arm against a piece of unistrut the ironworkers had failed to de-burr. The burr caused a laceration that required medical attention. This is a recordable, no lost time injury. The apprentice was released to work without limitations. The injury was caused by the action of another.

The second injury occurred in the Southwest division. A plumbing journeyman was installing pipe hangers, when a coworker on the floor below drilled into the deck and through the journeyman's shoe. He suffered a small puncture wound to his foot. The co-worker had tapped to announce that he was about to drill, but the injured journeyman did not react in time. This is a first aid injury. Please be aware of your surroundings and pre-plan how you will notify coworkers of your intentions.

WEEKLY TOPIC

-

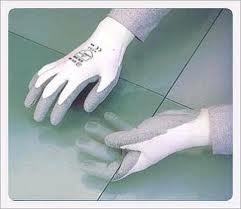

Sharp instruments and tools are essential to many kinds of work, but sharp or pointed objects can cause hazardous and often painful injuries. Injuries include cuts, punctures, nicks, and gashes that an lead to serious infections or diseases. These injuries can be prevented through employee training, protective gloves, machine guards, and proper maintenance.

-

-

Select the right tool for the job. Use sharp items only as they were designed. Sharpen cutting tools and knives on a regular basis. Dull blades require more force and may be more likely to slip, cutting the handler.

-

-

Wear gloves resistant to punctures,cuts,or moisture. Choose gloves normally expected for the task.

-

-

Let falling objects fall. Don't grab for falling cutting tools, sharp instruments, or glassware. It is better to clean up a mess or replace the item rather than risk injury or infection.

-

Store sharps safely. Take the time to ensure that instruments can be reached easily but pose no threat of injury. Don't carry loose sharp objects in your pocket. Store cutting instruments in drawers or racks when not in use.

-

Follow cleanup precautions at all times. Dispose of defective sharps properly. Wear gloves. Don't reach into wastebaskets or disposal containers with bare hands. Sharp material poking through bags can easily cut unprotected hands or legs. Check disposal bags before lifting to see if they are overloaded or likely to break. Lift plastic bags from their tie-off point and paper bags from their edges whenever possible and hold bags away from the body. Never "bear hug" a bag.

-

Make sure guards are in place on machinery with cutting blades.

-

Improper handling of sharp objects of sharp objects is one of the leading causes of injuries from them. Don't rush or take shortcuts when handling sharp equipment or tools. Protect yourself and others by handling sharp objects safely.

- Know the risks and Pre-plan the task

- Follow safe handling and disposal procedures

- Report all injuries and get proper medical treatment -

-

Protecting yourself and your coworkers is an important part of your job. The right combination of attitude and action can prevent most injuries from sharp instruments and tools.

OPPORTUNITY FOR IMPROVEMENT

-

Opportunities for improvement are ALWAYS welcome! Use the Opportunity for Improvement template on iAuditor to submit.

JOBSITE SAFETY CHECKLIST

-

Select date

-

Job Name:

-

Job Number:

-

Checked By:

-

Signature:

1. RECORDKEEPING

-

a. Notices, Posters (5-in1, OSHA Notice, Payroll)

-

b. Emergency Contacts

-

c. OSHA 300 Log

2. PERSONAL PROTECTIVE EQUIPMENT

-

a. In use: Safety glasses, Hard hats, Work boots, Gloves

-

b. Face shields or goggles used for overhead work

-

c. Respirators available

-

d. Welding screens

3. FIRST AID KITS

-

a. Available in gang box and job site trailer

-

b. Stocked adequately with gloves, bandages, and antiseptics

-

c. CPR and First Aid trained personnel

-

d. Medical facility location and contact information communicated

4. SCAFFOLDS

-

a. Competent person certified

-

b. Scaffold grade planking

-

c. Fall protection

-

d. Clear of debris / trash

5. LADDERS

-

a. Free from defects with safety feet, blocked, cleated, or otherwise secured.

-

b. Straight ladders at 1:4 pitch

6. CYLINDERS

-

a. Capped, stored in an upright position

-

b. Oxygen / Acetylene properly separated

-

c. Empty gas cylinders marked

7. TOOLS / EQUIPMENT

-

a. Inspected to ensure safe operating condition

-

b. Hand tools free from defects

-

c. Unsafe / Unusable tools / equipment tagged "Do Not Use"

-

d. Tools / Equipment properly guarded

8. HOUSEKEEPING

-

a. Maintained

-

b. Aisles and exit ways clear with 24" clearance

-

c. Work areas uncluttered and debris removed

9. ELECTRICAL

-

a. Electrical equipment grounded

-

b. Tools double insulated

-

c. Cords in good condition

-

d. Electrical panels covered if energized

10. FALL PROTECTION

-

a. Guard rails, mid rails, toe boards

-

b. Fall restraint systems

-

c. Open sides floors or platforms equipped with standard railing

-

d. Openings (interior / perimeter) properly barricaded or covered

11. FIRE PREVENTION

-

a. Flammable and explosive materials stored safely

-

b. Adequate number of fire extinguishers available with tags and clips

-

c. Vehicles and mobile equipment provided with extinguishers

12. EXCAVATIONS

-

a. Over 4 ft shored, benched, or sloped as required

-

b. Steps or ladders at 25 ft intervals

-

c. Competent person on site

13. HAZARD COMMUNICATION

-

a. MSDS and Labels available

-

b. Employees briefed on HAZCOM

-

c. HAZCOM information poster posted

-

d. Employees familiar with MSDS books and their location

COMMENTS

-

Type comments here or use "Sign" function to write:

-

Write here:

PRE-TASK PLAN

-

Ensure a Pre-Task Plan is completed on paper or via the iAuditor app.

CREW SIGNATURES

-

Add signature

-

Add signature

-

Add signature

-

Add signature

-

Add signature

-

Add signature

-

Add signature

-

Add signature

-

Add signature

-

Add signature

-

Add signature

-

Add signature

-

Add signature

-

Add signature

-

Add signature