Title Page

-

Site conducted

-

Conducted on

-

Prepared by

-

Location

Floors & Aisles

-

Floor and aisles are free of slip & trip hazards?

-

Designated walkways are plainly marked & free of stored or staged material?

-

Are non exit doors labeled?

-

Is fire equipment accessible and not blocked?

-

Are fire exit signs properly lighted?

-

Are evacuation maps posted?

-

Storage locations are identified and the proper items are being stored there?

-

Portable equipment such as fans, heater, etc., and cords operating these devices installed to not cause a trip hazard ?

Machinery & Equipment

-

Are all safety devices in place and functioning properly (interlocks, fences, light curtains, guards, etc.)?

-

The danger zones on or around machinery properly marked & identified?

-

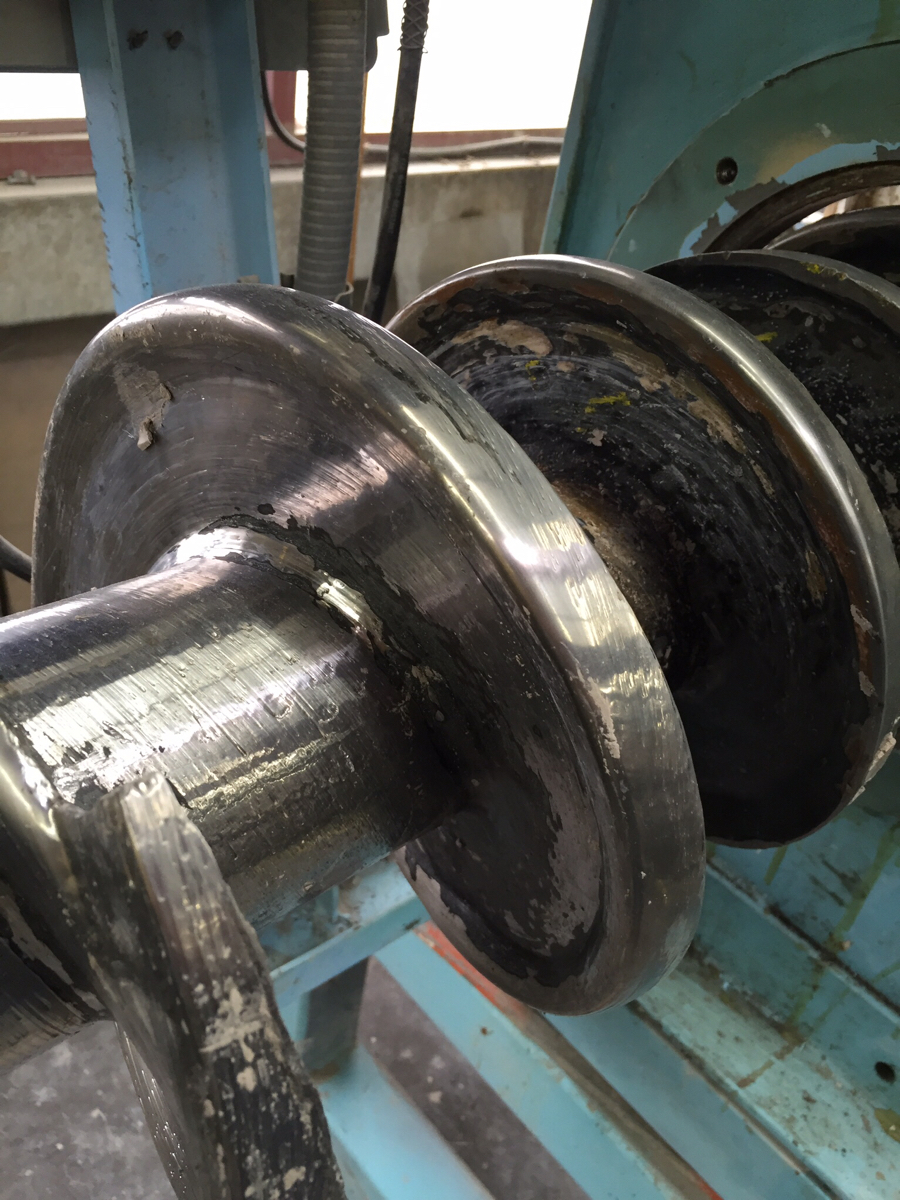

Have all machines been properly maintenanced according to manufacturers requirements?

-

Does the machinery have its lockout tagout procedure posted?

-

Are Work Instructions posted for all jobs?

-

Have all of the daily inspection checklists been completed for mobile equipment?

-

Is the machinery and equipment maintained in a neat & clean condition?

Material Handling & Storage

-

Are items stacked & stored in such a way to prevent them from falling over?

-

Are hazardous chemicals stored away from high traffic areas & in designated locations?

-

When lifting devices are used (slings, chains, forklift attachments) are they inspected & documented beforehand?

-

Are the handles on handcarts properly labeled with PUSH ONLY?

-

Is the weight limit on shelving posted?

Shipping Docks

-

Trailers are properly chocked?

-

Jackstands in place under front center of live load trailers?

-

Glad Hands Locks/Salvo system/Dock Locks operate properly according to SOP?

-

Docks are painted according to Dock Standard?

-

Dock cones and Lane Cones are in proper place and in good condition?

-

Dock chains or Dock gate are in place?

Maintenance Shop/Parts Room

-

Is flammable liquids cabinet orderly and door closed?

-

Is the floor area in front of electrical panels clear and assessable?

-

Are gas cylinders properly chained to the wall (if not in use)?

-

Is floor of main shop area neat and orderly?

-

Are fire extinguishers present in main shop and maintained?

-

Are guards in place on all hand tools being used?

-

Are TM's assigned specific areas to 5S after their shift?

Management

-

Is management visible on the floor? Who and how much?

-

Are TM's provided with adequate cleaning supplies?

-

Are cleaning supplies located and identified to their proper storage location?

-

Are hand tools and equipment stored in their proper locations? Is location identified?

-

Are TM's assigned specific areas to 5S after their shift?

Employee Observation

-

Are employees wearing all required personal protective equipment properly?

-

Is employee conducting work according to standard work instructions (WIS) or Standard Operating Procedure (SOP)?

-

Do you observe any employee doing an unsafe behavior?

-

Are employees using proper tool for the job?

-

Can employees identify the key safety hazard and protective procedure for the task they are conducting?

-

Are employees utilizing safe ergonomic practices?