Title Page

-

Conducted on

-

Prepared by

-

Location

- Hazard Identified

-

Document the findings with a photo:

-

List Hazard:

-

MMA's Recommendation:

-

Ensure Written program is updated annually with goals and objectives.

-

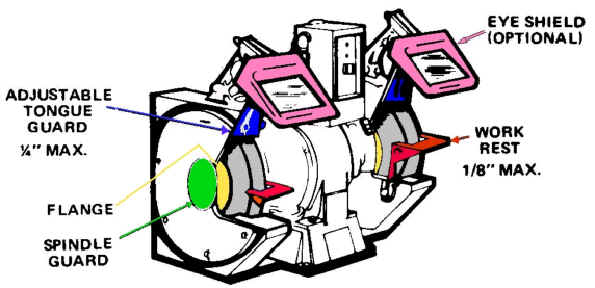

Ensure Guards are properly adjusted to 1/8" on tool rest & 1/4 inch on top guard. See photo for additional information:

-

Ensure that all cranes and hoists are inspected regularly, and that the inspection is documented.

-

Ensure that all excavations greater than 5 feet are protected with a protection system, trench box, sloping, shielding.

-

Ladders should be used for depths greater than 4 feet and should be spaced 25 feet apart.

-

Spoil Piles should be set back at least 2 feet from the edge of the excavation.

-

No bare wires should be seen through the insulation of wires.

-

Ensure all wiring components are guarded properly.

-

Electrical components should be grounded or double insulated.

-

Construction equipment should be used with a Ground Fault Circuit Interrupter (GFCI) at all times.

-

Strain Relief should be intact.

-

Ensure that all employees are Personal Fall Arrest System while in the work basket.

-

Ensure all hazardous substance containers are labeled properly with a GHS complaint label.

-

Ensure all employees are trained annually.

-

Ensure that all Fall Protection is inspected daily.

-

Guard all Open Side, Hole, Wall Opening

-

Ensure that fall protection is used when within 15’ of fall hazard on flat roof

-

Ensure that all fire extinguishers are not blocked at all times.

-

Ensure that all fire extinguishers are inspected at least monthly (in-house) & Annual (third party).

-

Ensure that all fire extinguishers gauges are in the green.

-

Ensure that all ladders are stored properly to prevent falling.

-

Ensure that all ladders are inspected before use, and any damaged ladders are removed from service or red-tagged.

-

Ensure the proper type and use of ladders is being followed. Training of employees about proper ladder use.

-

Ensure that LOTO Procedures are written for all dual energy machines.

-

Ensure that LOTO training is conducted for both authorized and affected employees.

-

Ensure that all LOTO Procedures are audited on an annual basis.

-

Ensure that all Point of Operation is guarded to protect employees from coming in contact with the Point of Operation.

-

Ensure that PPE is proper for the hazards trying to protect against.

-

Ensure that PPE is in good working order.

-

Ensure that PPE is ANSI or ASME rated.

-

Ensure that Forklifts are inspected daily.

-

Ensure that Forklift Damage is reported and repaired.

-

Ensure that Forklifts are parked and turned off when operator is greater than 25 feet away or out of site of the forklift.

-

Ensure that Carbon Monoxide testing is completed & documented quarterly for environmental exposure, not just tail pipe testing.

-

Ensure that all Respirators are cleaned, stored, and used in appropriate manner.

-

Ensure that all employees have signed Appendix D when using voluntarily.

-

Ensure all required users are trained, medically evaluated, and fit tested annually as required by the Respiratory Protection Standard.

-

Ensure that Scaffolds are Tied/Secured >4:1 Base height

-

Ensure that guardrail system is not missing or incomplete.

-

Ensure that all pins are in place.

-

Ensure that proper Foundation/Base is being used.

-

Enter Recommendation here:

-

Enter Recommendation Here:

-

Potential OSHA Penalties

Corrective Action:

-

Corrective Action Taken:

-

Corrective Action completed:

-

Verification of corrective action: