Information

-

Document No.

-

Audit Title

-

Client / Site

-

Conducted on

-

Prepared by

-

Location

-

Personnel

-

Facility ID Number

Dispenser Area

-

Dispenser Sumps

-

Clean and Empty - No water, product debris

-

Sump Integrity - no leaks, cracks, bulges, holes

-

Leak Detection Sensor - Correct position and height

-

Piping Components

-

No abnormal appearance of piping or components (rust, discoloration, delimitation, swelling)

-

Test boot (if applicable) pulled back so interstice is not blocked or obstructed

-

Product Shear Valve

-

Properly secured and anchored. Installed at the proper level with no leaks.

-

Vapor Shear Valve (for Stage II Vapor Recovery Systems only)

-

Properly secured and anchored

-

Installed at the proper level

-

Flex Connectors

-

No leaks

-

Not in contact with soil (without catholic protection) or debris

Leak Detection Equipment

-

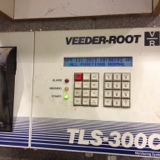

Automatic Tank Gauging System

-

Leak test pass?

-

No Sensor alarms

-

Alarm history clear of alarms

-

Water alarm clear

-

Paper loaded (if applicable)

-

Interstitial Monitoring

-

Manual Inspection if used for release detection.

-

Manual Inventory Control

-

Inventory Reconciled

-

Automatic Line Leak Detection

-

No leaks in the leak detector

-

Soil Vapor Monitoring

-

Covers clearly marked and secured

-

Groundwater Monitoring

-

Covers clearly marked and secured

-

Water present in wells

-

No product present in wells.

Tank Area

-

Tanks

-

Inspect for water

-

Observation Wells

-

Cover is tightly sealed, properly identified and secured

-

Cap is water tight and locked

-

Tank Venting Equipment

-

Pressure/vacuum vent cap present (if required)

-

Spill Containment Manholes

-

Cover is in good condition and properly identified

-

Clean, empty and dry - No water, product, dirt, debris

-

Sump integrity - No cracks, bulges, holes

-

No abnormal appearance of piping

-

Containment Sump Manholes

-

Cover is in good condition and properly identified

-

Containment Sump

-

Cover is in good condition and properly identified

-

Clean, empty and dry - No water, product, dirt, debris

-

Sump integrity - No cracks, bulges, holes

-

Sump Sensors

-

Correct position and height, and operational

-

Flex Connectors

-

No leaks

-

Not in contact with soil (without catholic protection) or debris

-

Stage I Vapor Recovery Manholes Two-Point (dual point)

-

Cover is in good condition and properly identified

-

Sump (if present) integrity - No cracks, bulges, holes

-

Dry break poppet cap tightly sealed

-

Poppet seals tightly and moves freely when depressed.

Corrosion Protection (if necessary)

-

Impressed Current Cathodic Protection

-

Rectifier is operating within normal limits

Certification

-

Signature