Title Page

-

Document No.

-

Audit Title

-

Client / Site

-

Conducted on

-

Prepared by

-

Location

-

Personnel

Previous inspection

-

Has the last inspection been reviewed?

-

Have all outstanding actions been rectified?

Welfare

-

Are the facilities clean, tidy and uncluttered?

-

Is the fridge clean?

-

Is the microwave clean?

-

Are all dishes washed and stored away appropriately?

-

Bins at a satisfactory fill level?

-

Cleaning rota signed off?

-

Toilet clean and tidy?

-

Adequate heating?

First Aid

-

Are cabinets and contents clean, orderly and clearly labelled?

-

Are the contents regularly checked?

-

No contents past their expiry date?

-

Employees aware of location of first aid cabinet?

-

Are trained first aid officers accessible?

-

Are emergency numbers displayed?

-

Are eye washes and showers available and easily accessed?

Fire Prevention

-

Evacuation plan displayed and understood by all employees?

-

Evacuation procedures discussed regularly? (3 to 4 times a year)

-

Extinguishers in place and clearly marked for type of fire?

-

Extinguishers recently serviced?

-

Extinguishers clear of any obstructions?

-

Adequate directional notices for fire exits?

-

Fire exits clear of obstructions?

-

Fire alarm system functioning correctly?

Access/Egress

-

Entry and walkways kept clear?

-

Entry and exit doors clear from obstructions?

-

Appropriate walkway signage?

Fixed Plant

-

Are all guards present and in good condition?

-

Conveyors belts in good condition?

-

Emergency stopping devices in working condition?

-

Overall In sound condition?

-

Daily and weekly check sheets completed?

-

Maintenance up to date?

-

Adequate lighting?

-

Are noise levels being controlled?

-

Are provisions in place to reduce any bending and stooping requirements?

-

Are lockout procedures implemented and followed?

PPE

-

Is all required PPE being worn?

-

Is it all in good order?

-

Issued items signed for?

-

Mandatory PPE available and in date?

Mobile Plant

-

Are daily checks sheets completed?

-

Is schedule maintenance performed?

-

In overall sound condition - tyres, brakes etc.

-

All lights in working condition - check operation of brakes, indicator and reversing lights?

-

Can condition acceptable?

-

Fire extinguisher available?

-

General overall good clean condition?

Chemicals

-

Are chemical based liquids stored appropriately?

-

Are material safety data sheets available for all chemicals?

-

COSHH assessments completed for hazardous substances?

-

All containers labelled correctly?

-

Unused substances disposed of?

-

Employees trained in the use of hazardous substances?

Electrical

-

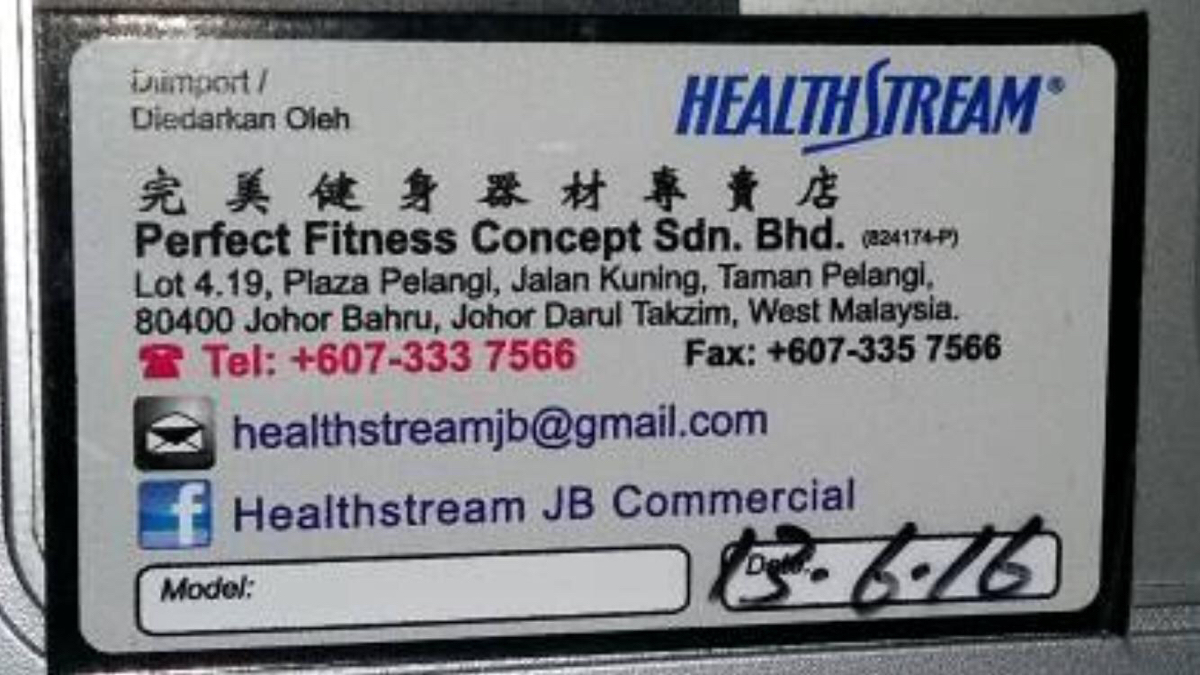

Portable appliance tested and labelled?

-

Safety switches tested every six months and recorded?

Housekeeping

-

Are the floors around the machines kept clear from slips, trips and falls?

-

Are open floor areas kept clear from slips, trips and falls?

-

Is wind blown litter being controlled?

-

Are liquid spills removed quickly?

-

Spillage kits close to liquid storage?

-

Waste bins located at suitable points throughout site?

-

Bins emptied regularly?

-

Oily rags and combustible materials stored appropriately?

-

Stockpiles at a manageable level?

-

Are the stockpiles free of any contamination?

-

Are bunds adequate and being maintained?

-

Are procedures being followed for non conforming wastes?

-

Are all tools in good working condition and when not in use stored correctly?

Office

-

Office furniture in good condition?

-

Good natural lighting?

-

Noise environment acceptable?

-

Screen based equipment positioned to reduce glare from windows etc?

-

Tasks designed to prevent occupational overuse syndrome? (breaks included)

-

Air conditioning systems regularly maintained?

Any additonal issues

-

Add media

Sign Off

-

On site representative

-

Select date

-

Auditor's signature

-

Select date