Title Page

-

Project Name

-

Project Number

-

Conducted on

Overview

Construction Project Overview

-

Project Description:

-

Project Start Date:

-

Project End Date:

-

Project Manager/Coordinator:

- Andrew Miller

- Neil Stock

- Pat Esgar

- Duane Kellinger

- Other

-

Will Facilities Management staff be involved with the project?

-

Will contractors be required for this project?

-

Construction Superintendant/Lead:

-

Electrical Work:

- Not Required

- Durango Electric

- Kenny Electric

- Blake Mechnical

- Other

-

Communications:

- Not Required

- Sterling Communications

- AT&T

- Verizon

- Other

-

Plumbing Work:

- Not Required

- JT Plumbing

- Other

-

Fabrication Work:

- Not Required

- Holt Sheetmetal

- Stinger Welding

- Garr Mechanical

- Other

-

Flooring Work:

- Not Required

- Commercial Flooring Solutions

- Other

-

Case Work:

- Not Required

- Office Outfitters

- Closets Plus

- Other

-

Landscaping:

- Not Required

- True Blue

- Other

Required Assessments

-

Select the applicable assessments required for this project and an email will be sent to the responsible person to complete. If one of the following conditions exist then all 3 assessments will need to be completed:

- The project involves more than routine maintenance or repair.

- The project involves a Life Safety, Infection Control, and Environment of Care risk.

- The project has contractors or subcontractors completing the work.

For routine maintenance or repair that is being completed by just the Facilities Management staff the assessments can be tailored to the work being performed. If there is any question a joint decision should be made between the Safety Officer, Life Safety Officer, and Infection COntrol Manager. -

Safety and EOC Risk Assessment (SERA) required?

-

Completed by Safety Officer

-

Infection Control Risk Assessment (ICRA) Required?

-

Completed by Infection Prevention Manager

-

Interim Life Safety Measure (ILSM) Assessment Required?

-

Completed by Facilities Management Manager

CDPS Plan Review/Permit

-

CDPS Plan Review/Permit Required?

-

Falls under limited scope?

Safety and EOC Risk Assessment (SERA)

Safety and EOC Risk Assessment (SERA)

-

Is a Safety and EOC Risk Assessment Required?

NOISE Explanation: Construction or Demo Activities Create Noise at Moderate to High Levels (i.e. Saw Cutting Concrete, Hammer Drills, Coring, Etc)

-

Will there be noise generated from construction and demo operations?

-

Actions to Mitigate Risk

-

Install Noise Barrier

-

Isolate Noise Producing Activity

-

Coordinate Noisy Work with Affected Departments

-

Relocate Current Occupants to Another Unit (i.e., Patients, Staff, Classes, Animals, Research)

-

Utilize Newer Tools that are Less Noisy

-

Notification to Impacted Area Staff/Building Coordinator

-

Alert Adjacent Floors of Time for Conducting Noisy Activities

-

Additional Notes

VIBRATION Explanation: Jackhammer, Heavy Machinery, Vibration Producing Equipment

-

Will there be vibrations created during construction and demo operations?

-

Actions to Mitigate Risk

-

Install Vibration Isolation Materials

-

Coordinate Vibration Work with Affected Departments

-

Relocate Current Occupants to Another Unit (i.e., Patients, Staff, Classes, Animals, Research)

-

Utilize Newer Tools that are Less Vibration

-

Notification to Impacted Area Staff/Building Coordinator

-

Alert Adjacent Floors of Time for Conducting Noisy Activities

-

Additional Notes

ENVIRONMENTAL HAZARDS Explanantion: Odors, VOCs, Potential Airborne Hazardous Materials, Vapors, Mold, Asbestos, Water, Changes in Temperature, Dusts, Air Balance, Etc.

-

Will there be environemntal hazards created from construction and demo operations?

-

Actions to Mitigate Risk

-

Substitute with Less Hazardous Material

-

Use Methods to Monitor Hazardous Material Exposure

-

Infection Risks/Dust Producting Activities (If Yes, ICRA Required)

-

Remove or Isolate HVAC System

-

Protect Workers from Nearby Hazardous Exhausts

-

Prevent Hazardous Materials from Entering HVAC Returns and Intakes

-

Water Mist Work Surfaces to Minimize Dust

-

Utilize Sticky Walk Off Mats

-

Transport Process Designed to Minimize Particulate Matter/Debris

-

Construct Anteroom

-

Establish Negative Pressure

-

Asbestos Protective Measures

-

Routine Painting (Minimal Wet Sanding or Patching)

-

Maintain MSDS Sheets on Products to be Used Prior to Starting Work

-

Protect Storm Water Drains

-

Additional Notes

UTILITY SHUTDOWN Explanation: Increased Risk of Failure. All Shutdown Requests Require 48 hours Advance Notice.

-

Will there be planned utility shutdowns during construction and demo operations?

-

Select the applicable utilities to be shutdown.

- Electricity

- Elevators

- Emergency Power

- HVAC (to include chilled and heating water)

- Medical Gas

- Natural Gas

- Nurse Call System

- Pnuematic Tube System

- Overhead Paging System

- Sewage

- Steam

- Vacuum

- Water

-

Additional Notes

FIRE / LIFE SAFETY Explanation: Hot Works, Fire Suppression System Work, Egress Limitations, Potential Fire Hazards

-

Will there be fire/life safety concerns during construction and demo operations?

-

Construction Related Activities (must evaluate all projects for potential risk of fire) (If Yes, ILSM Required)

-

Hot Work (e.g. flame, arc and spark producing) (If Yes, ILSM and Hot Works Permit Required)

-

Fire Suppression System Shutdown (e.g. Sprinklers, Halon, etc.) (If Yes, ILSM Required)

-

Fire Alarm System Shutdown (If Yes, ILSM Required)

-

Limit Access/Egress (If Yes, ILSM Required)

-

Fire Alarm System Component Modifications (e.g. Smoke Detectors, Strobes, etc) (If Yes, ILSM Required)

-

Ceiling System Removal (If Yes, ILSM Required)

-

Additional Notes

FIRE/SMOKE WALL PENETRATION

-

Will there be any work that creates or alters penetrations through smoke/fire walls during construction?

-

Refill new and pre-existing penetrations with adequate sealant? (Contact maintenance if unsure of sealant type required)

SECURITY

-

Will construction and demo operations be conducted in security sensitive areas?

-

Select the applicable areas.

- Cashiers Office

- Electrical Rooms

- Emergency Department

- Human Resources

- Hospital Adminisatration

- ICU

- Main Lab

- Medical Records

- MRI

- Nuclear Medicine

- Pediatric Inpatient (TCU)

- Pharmacy (Inpatient)

- Pharmacy (Outpatient)

- Radiology

- Server or Comm Rooms

- Surgery (Inpatient)

- Surgery (Outpatient)

- Women's Services (FBC, NICU, Nursery)

-

Additional Notes

-

Will security systems be disrupted during construction and demo operations?

-

Select the applicable security systems.

- Access Control System

- Camera System

- Infant Abduction System

- Panic Button System

-

Additional Notes

-

Where contractors briefed on RepTrax process and identification/access control requirements?

TEMPORARY CRANE USE

-

Will a crane be used during construction and demo operations?

-

Notify House Supervisor

-

Notify Security; traffic control (vehicular & pedestrian)

-

Notify Emergency Department (List departments in the notes)

-

Notify Affected Departments

-

Additional Notes

RADIATION

-

Will contractors be working in areas where exposure to radiation may be possible?

-

Actions to Mitigate Risks

-

Personnel Badged (Dosimetry Monitoring Badge)

-

Personnel Trained by Mercy Radiation Safety Officer

-

Additional Notes

Hazardous Materials and Waste

-

Will hazardous chemicals be used during construction and demo operations?

-

Personnel Trained (Spills/Risks)

-

Chemicals properly stored (Flammables)

-

Chemicals properly labeled by GHS standards

-

Safety Data Sheets for chemicals on-site available

-

Will hazardous waste be generated during construction and demo operations?

-

Personnel Trained (Waste Disposal)

Other Work being Performed

-

Will Lock Out Tag Out (LOTO) need to be utilized?

-

Staff trained

-

Communicate with Facilities Management before performing LOTO of a system.

-

Confined Work Spaces

-

Personnel Trained

-

Obtain confined space permit (Contact facilities management if no program)

-

Trenching

-

Shoring

Infection Control Risk Assessment (ICRA) Assessment

-

Is an Infection Control Risk Assessment required?

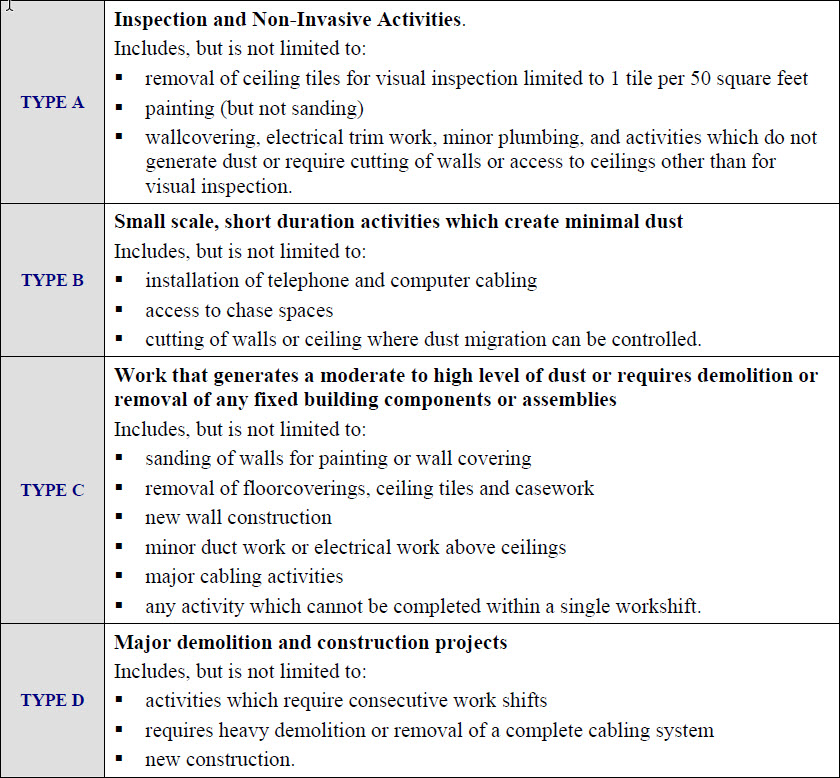

Step 1:

-

Use the following table to identify the Type of Construction Activity (Type A-D)

-

Type of Construction Activity:

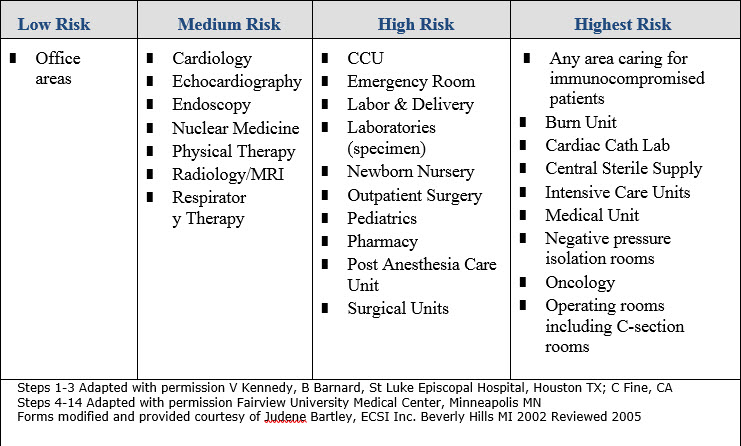

Step 2:

-

Use the following table to identify the Patient Risk Group; if more than one risk group will be affected then select the higher risk group.

-

Patient Risk Group:

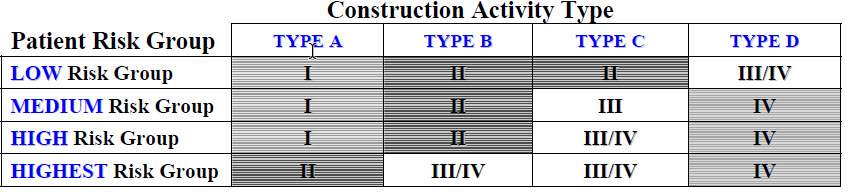

Step Three:

-

Use the following table to match the "Type of Construction Activity" and the "Patient Risk Group" from Step 1 and 2 to find the "Class of Infection Control Precautions Required".

-

NOTE: Infection Prevention Manager will be required to sign for the ICRA if the "Class of Infection Control Precautions Required" is a CLASS III or IV.

-

Class of Infection Control Precautions Required:

-

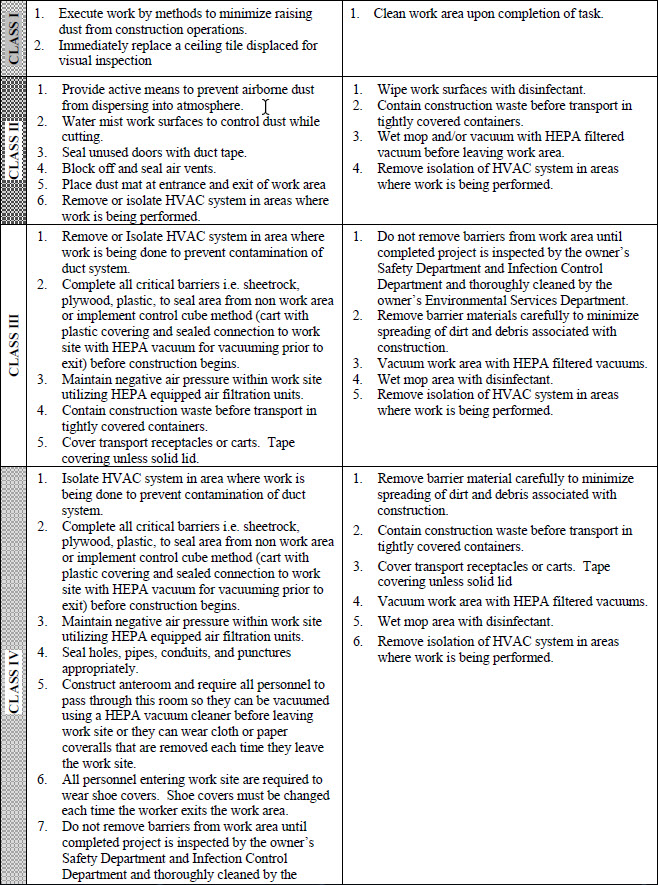

Use the following chart to identify the infection control precautions required per the identified class above.

Step 4:

-

Identify the areas surrounding the project area and assess for potential impact by identifying Risk Group.

-

Department Below, Risk Group:

-

Department Above, Risk Group:

-

Department Lateral, Risk Group:

-

Department Lateral, Risk Group:

-

Department Behind, Risk Group:

-

Department Front, Risk Group:

Step 5:

-

Identify specific site activity (e.g. patient room, medication room, etc.).

Step 6:

-

Identify issues related to ventilation, plumbing, HVAC, and electrical in terms of occurence of probable outages.

Step 7:

-

Identify containment measures using chart from Step 3. What types of barriers (e.g. plastic, solid wall barriers)? Will HEPA filtration be required?

-

NOTE: Renovation/construction area shall be isolated from the occupied areas during construction/demo and shall be negative pressure with respect to surrounding areas.

Step 8:

-

Consider potential risk of water damage. Is there a risk due to compromising structural integrity (e.g. walls, ceiling, roof)?

Step 9:

-

Consider disruption to patient care areas. Can work be completed during non-patient care hours?

Step 10:

-

Do the plans allow for adequate number of isolation/negative airflow rooms?

Step 11:

-

Do the plans allow for an adequate number and type of hand washing sinks?

Step 12:

-

Does the Infection Control staff agree with the minimum number of sinks?

-

Verify against AIA guidelines for types and area.

Step 13:

-

Does the Infection Control staff agree with the plans relative to clean and soiled utility rooms?

Step 14

-

Does the plan include guidelines for containment issues (e.g. traffic flow, housekeeping, how and when to complete debris removal, etc.)?

-

Identify and communicate the responsibility for project monitoring that includes infection control concerns and risks. The ICRA may be modified throught the duration of the project. Revisions must be communicated to the Project Coordinator and the Contractor FM/Lead.

Infection Control Construction Permit

Infection Control Construction Permit

-

Is a Infection Control Construction Permit Required?

-

Permit #

-

Location of Construction

-

Estimated Duration

-

Project Coordinator

-

Contractor(s) Performing Work

-

Supervisor

-

Permit Expiration Date

-

Telephone

CONSTRUCTION ACTIVITY

-

TYPE A: Inspection, non-invasive activity

-

TYPE B: Small scale, short duration, moderate to high levels

-

TYPE C: Activity generates moderate to high levels of dust, requires greater 1 work shift for completion

-

TYPE D: Major duration and construction activities Requiring consecutive work shifts

INFECTION CONTROL RISK GROUP

-

GROUP 1: Low Risk

-

GROUP 2: Medium Risk

-

GROUP 3: Medium/High Risk

-

GROUP 4: Highest Risk

CLASS PROJECT TYPE

-

Select Class

- CLASS I

- CLASS II

- CLASS III

- CLASS IV

-

CLASS I

1. Execute work by methods to minimize raising dust from construction Operations.

2. Immediately replace any ceiling tile displaced for visual inspection.

3. Minor Demolition for Remodeling. -

CLASS II

1. Provides active means to prevent air-borne dust from dispersing into atmosphere

2. Water mist work surfaces to control dust while cutting.

3. Seal unused doors with duct tape.

4. Block off and seal air vents.

5. Wipe surfaces with disinfectant.

6. Contain construction waste before transport in tightly covered containers.

7. Wet mop and/or vacuum with HEPA filtered vacuum before leaving work area.

8. Place dust mat at entrance and exit of work area.

9. Remove or isolate HVAC system in areas where work is being performed. -

CLASS III

1. Obtain infection control permit before construction begins.

2. Isolate HVAC system in area where work is being done to prevent contamination of the duct system.

3. Complete all critical barriers or implement control cube method before construction begins.

4. Maintain negative air pressure within work site utilizing HEPA equipped air filtration units.

5. Do not remove barriers from work area until complete project is thoroughly cleaned by Env. Services Dept.

6. Vacuum work with HEPA filtered vacuums.

7. Wet mop with disinfectant

8. Remove barrier materials carefully to minimize spreading of dirt and debris associated with construction.

9. Contain construction waste before transport in tightly covered containers.

10. Cover transport receptacles or carts. Tape covering.

11. Remove or isolate HVAC system in areas where work is being performed/ -

Additional Requirements:

-

Initial

-

Date

-

CLASS IV

1. Obtain infection control permit before construction begins.

2. Isolate HVAC system in area where work is being done to prevent contamination of duct system.

3. Complete all critical barriers or implement control cube method before construction begins.

4. Maintain negative air pressure within work site utilizing HEPA equipped air filtration units.

5. Seal holes, pipes, conduits, and punctures appropriately.

6. Construct anteroom and require all personnel to pass through this room so they can be vacuumed using a HEPA vacuum cleaner before leaving work site or they can wear cloth or paper coveralls that are removed each time they leave the work site.

7. All personnel entering work site are required to wear shoe covers

8. Do not remove barriers from work area until completed project is thoroughly cleaned by the Environmental Service Dept.

9. Vacuum work area with HEPA filtered vacuums.

10. Wet mop with disinfectant.

11. Remove barrier materials carefully to minimize spreading of dirt and debris associated with construction.

12. Contain construction waste before transport in tightly covered containers.

13. Cover transport receptacles or carts. Tape covering.

14. Remove or isolate HVAC system in areas where work is being performed.

Sign Off

-

Exceptions/Additions to this permit are noted by attached memoranda

-

Permit Request By

-

Permit Authorized By

Interim Life Safety Measure (ILSM) Assessment

Interim Life Safety Measure Assessment/Result

-

Is a Life Safety Measure Assessment required?

Guidelines for Conducting ILSM Assessments

-

1) The assessment is a product of an ASHE engineer and is designed for use in determining which Life Safety Measures should be implemented based on code deficiencies, construction related issues, or maintenance and testing requirements.

2) The assessment is used by selecting "Yes" for each deficiency or construction condition and then following the measures indicated below for that deficiency.

3) If all deficiencies have "No" selected then this identifies that ILSM are not required.

Code Deficiencies

-

Lacking a code complying smoke barrier?

-

Increase surviellance of buildings, grounds, and equipment; giving special attention to construction areas, storage areas, excavation, and field offices.

-

Conduct education to promote awareness of building deficiencies, construction hazards, and temporary measures implemented to maintain fire safety.

-

Conduct training on how to compensate for impaired structural or compartmental fire safety features.

-

Fire exit stairs discharge improperly?

-

Post signage identifying the location of alternate exits to everyone affected.

-

Conduct additional fire drill per shift per quarter.

-

Conduct education to promote awareness of building deficiencies, construction hazards, and temporary measures implemented to maintain fire safety.

-

Conduct training on how to compensate for impaired structural or compartmental fire safety features.

-

Excessive travel distance to an approved exit?

-

Post signage identifying the location of alternate exits to everyone affected.

-

Increase surviellance of buildings, grounds, and equipment; giving special attention to construction areas, storage areas, excavation, and field offices.

-

Enforce housekeeping of storage areas and debris removal practices that could reduce the buidlings flammable and combustible fire load to the lowest feasible level.

-

Conduct additional fire drill per shift per quarter.

-

Lack of 2 remote exits?

-

Post signage identifying the location of alternate exits to everyone affected.

-

Increase surviellance of buildings, grounds, and equipment; giving special attention to construction areas, storage areas, excavation, and field offices.

-

Enforce housekeeping of storage areas and debris removal practices that could reduce the buidlings flammable and combustible fire load to the lowest feasible level.

-

Conduct additional fire drill per shift per quarter.

-

Conduct education to promote awareness of building deficiencies, construction hazards, and temporary measures implemented to maintain fire safety.

-

Conduct training on how to compensate for impaired structural or compartmental fire safety features.

-

Noncomforming building construction type?

-

Increase surviellance of buildings, grounds, and equipment; giving special attention to construction areas, storage areas, excavation, and field offices.

-

Enforce housekeeping of storage areas and debris removal practices that could reduce the buidlings flammable and combustible fire load to the lowest feasible level.

-

Conduct education to promote awareness of building deficiencies, construction hazards, and temporary measures implemented to maintain fire safety.

-

Conduct training on how to compensate for impaired structural or compartmental fire safety features.

-

Improperly protected vertical openings?

-

Increase surviellance of buildings, grounds, and equipment; giving special attention to construction areas, storage areas, excavation, and field offices.

-

Enforce housekeeping of storage areas and debris removal practices that could reduce the buidlings flammable and combustible fire load to the lowest feasible level.

-

Large penetrations in fire barriers?

-

Increase surviellance of buildings, grounds, and equipment; giving special attention to construction areas, storage areas, excavation, and field offices.

-

Enforce housekeeping of storage areas and debris removal practices that could reduce the buidlings flammable and combustible fire load to the lowest feasible level.

-

Conduct education to promote awareness of building deficiencies, construction hazards, and temporary measures implemented to maintain fire safety.

-

Conduct training on how to compensate for impaired structural or compartmental fire safety features.

-

Corridor walls do not extend across to the structure?

-

Increase surviellance of buildings, grounds, and equipment; giving special attention to construction areas, storage areas, excavation, and field offices.

-

Enforce housekeeping of storage areas and debris removal practices that could reduce the buidlings flammable and combustible fire load to the lowest feasible level.

-

Hazardous areas not properly protected?

-

Increase surviellance of buildings, grounds, and equipment; giving special attention to construction areas, storage areas, excavation, and field offices.

Construction Related Isssues

-

Blocking off an approved exit?

-

Post signage identifying the location of alternate exits to everyone affected.

-

Inspect exits in affected areas on a daily basis.

-

Increase surviellance of buildings, grounds, and equipment; giving special attention to construction areas, storage areas, excavation, and field offices.

-

Enforce housekeeping of storage areas and debris removal practices that could reduce the buidlings flammable and combustible fire load to the lowest feasible level.

-

Conduct additional fire drill per shift per quarter.

-

Conduct education to promote awareness of building deficiencies, construction hazards, and temporary measures implemented to maintain fire safety.

-

Conduct training on how to compensate for impaired structural or compartmental fire safety features.

-

Rerouting of traffic to Emergency Department?

-

Post signage identifying the location of alternate exits to everyone affected.

-

Conduct education to promote awareness of building deficiencies, construction hazards, and temporary measures implemented to maintain fire safety.

-

Renovation on an occupied floor?

-

Post signage identifying the location of alternate exits to everyone affected.

-

Inspect exits in affected areas on a daily basis.

-

Provide temporary but equivalent fire alarm and detection systems for use when a fire system is impaired (Fire Watch).

-

Provide additional fire fighting equipment.

-

Use temporary construction partitions that are made of noncombustible material or made of limited combustible materialthat will not contribute to the spread of fire.

-

Increase surviellance of buildings, grounds, and equipment; giving special attention to construction areas, storage areas, excavation, and field offices.

-

Enforce housekeeping of storage areas and debris removal practices that could reduce the buidlings flammable and combustible fire load to the lowest feasible level.

-

Inspect and test temporary fire systems monthly.

-

Provide additional training on the use of firefighting equipment.

-

Conduct education to promote awareness of building deficiencies, construction hazards, and temporary measures implemented to maintain fire safety.

-

Replacing fire alarm system (Out-of-Service)?

-

Notify fire department (Fire Watch <4 hours).

-

Provide temporary but equivalent fire alarm and detection systems for use when a fire system is impaired (Fire Watch).

-

Increase surviellance of buildings, grounds, and equipment; giving special attention to construction areas, storage areas, excavation, and field offices.

-

Enforce housekeeping of storage areas and debris removal practices that could reduce the buidlings flammable and combustible fire load to the lowest feasible level.

-

Inspect and test temporary fire systems monthly.

-

Provide additional training on the use of firefighting equipment.

-

Conduct additional fire drill per shift per quarter.

-

Installing sprinkler system (Out-of-Service)?

-

Notify fire department (Fire Watch <4 hours).

-

Provide temporary but equivalent fire alarm and detection systems for use when a fire system is impaired (Fire Watch).

-

Provide additional fire fighting equipment.

-

Increase surviellance of buildings, grounds, and equipment; giving special attention to construction areas, storage areas, excavation, and field offices.

-

Enforce housekeeping of storage areas and debris removal practices that could reduce the buidlings flammable and combustible fire load to the lowest feasible level.

-

Inspect and test temporary fire systems monthly.

-

Provide additional training on the use of firefighting equipment.

-

Conduct additional fire drill per shift per quarter.

-

Significanlty modifying smoke or fire barrier walls?

-

Use temporary construction partitions that are made of noncombustible material or made of limited combustible materialthat will not contribute to the spread of fire.

-

Increase surviellance of buildings, grounds, and equipment; giving special attention to construction areas, storage areas, excavation, and field offices.

-

Enforce housekeeping of storage areas and debris removal practices that could reduce the buidlings flammable and combustible fire load to the lowest feasible level.

-

Conduct additional fire drill per shift per quarter.

-

Conduct education to promote awareness of building deficiencies, construction hazards, and temporary measures implemented to maintain fire safety.

-

Hot work?

-

Provide additional fire fighting equipment.

-

Use temporary construction partitions that are made of noncombustible material or made of limited combustible materialthat will not contribute to the spread of fire.

Maintenance and Testing

-

Taking a fire alarm system out-of-service?

-

Notify fire department (Fire Watch <4 hours).

-

Provide temporary but equivalent fire alarm and detection systems for use when a fire system is impaired (Fire Watch).

-

Inspect and test temporary fire systems monthly.

-

Provide additional training on the use of firefighting equipment.

-

Conduct additional fire drill per shift per quarter.

-

Conduct education to promote awareness of building deficiencies, construction hazards, and temporary measures implemented to maintain fire safety.

-

Taking a sprinkler system out-of-service?

-

Notify fire department (Fire Watch <4 hours).

-

Provide temporary but equivalent fire alarm and detection systems for use when a fire system is impaired (Fire Watch).

-

Provide additional fire fighting equipment.

-

Inspect and test temporary fire systems monthly.

-

Provide additional training on the use of firefighting equipment.

-

Conduct additional fire drill per shift per quarter.

-

Conduct education to promote awareness of building deficiencies, construction hazards, and temporary measures implemented to maintain fire safety.

-

Disconnecting alarm devices?

-

Notify fire department (Fire Watch <4 hours).

-

Provide temporary but equivalent fire alarm and detection systems for use when a fire system is impaired (Fire Watch).

-

Inspect and test temporary fire systems monthly.

-

Provide additional training on the use of firefighting equipment

ILSM Assessment Result

-

Based on Assessment; ISLM required?

-

Complete the items under each applicable section above marked "Yes".