Information

-

Country & Branch:

-

Date:

-

Time:

-

Location (Service Site & Branch Site):

-

Type of Work Observed:

-

MSOT By (Name):

-

MSOT By (Job Title):

-

Technician / Staff (Name):

-

Technician / Staff (Job Title):

What To Look Out For In Technician

-

NOTE : Section A to G are to be used to evaluate individual Technician.

INSTRUCTION:

Please choose -

✔ “Good Condition/ Good Practice” or “Yes”

X “Not in Good Condition/ Unsafe Practice” or “No”

P “Partially Good / Partial Understanding”

✱ Copy of MSOT report should be forwarded to the Country SHE Manager.

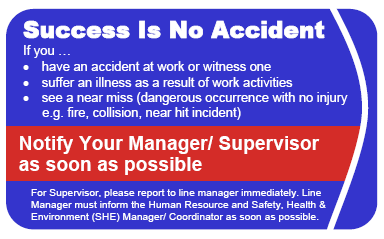

A) INCIDENT REPORTING (SINA)

-

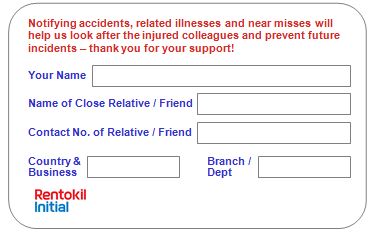

1(a) Employee carried “SINA card” with him & in good condition

-

-

1(b) Back of “SINA Card” is completed & info. remain accurate

-

-

1(c) Able to explain purpose of the SINA card

-

1(d) Employee knows what to report and who to report to <br>(near miss, minor, serious injury, non-injury case e.g. vehicle damage, fire)<br>

-

1(e) Witness/ encounter any near miss, injury or illness in the last 1 year

B) BASIC SAFETY RULES

-

1. Is Technician following the rules below while at work?

-

NOTE : Please indicate NA if any item is not applicable or not inspected during the MSOT.

-

1(a) Safety shoes

-

1(b) Seat belt worn by driver and passenger

-

1(c) No hand-held hand phone use while driving a vehicle or motorbike

-

1(d) No use of hand phone while operating equipment

-

1(e) Motorbike helmet, jacket and gloves worn while riding motorbike

-

1(f) Cartridge Filter Respirator worn while spraying/ fogging/ misting/ ULV/ fumigation

-

C) SHE GOLDEN RULES

-

1. Does Technician have the “SHE Golden Rules Booklet”?

-

2. Can Technician explain the SHE Golden Rules under “Start/ Stop”? <br> Did he/ she comply with the rules at work?

-

ANSWER :

➊ Only start work if you:

a) are trained and authorised to do the work

b) are fit for work and unaffected by drugs or alcohol

c) have the right equipment, PPE and safety footwear

d) understand the hazards and taken precautions

➋ Do not start work if for any reason, you feel that it is not safe to do so. If in doubt, contact your manager.

➌ Stop work if there is immediate risk / danger to your safety and contact your manager. -

3. Can Technician explain the 5 SHE Golden Rules on “Work At Height”?

-

ANSWER :

➊ Last Resort ~ Only work at height if all other ways have been considered and ruled out.

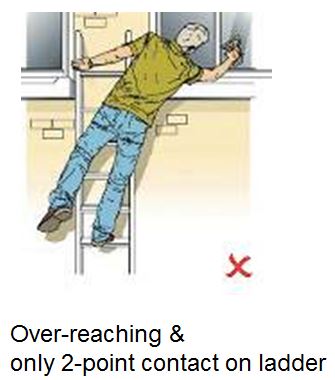

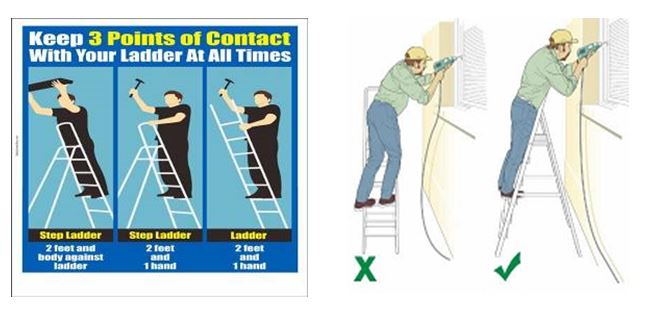

➋ Only use a ladder if 3 points of contact can be made and no over-reaching is required to access a position.

➌ Use of equipment to prevent falls (e.g. barricade) must be given priority over the use of fall arrest equipment (e.g. harness & lifeline).

➍ Do not stand on fragile surface, or work near unguarded edge or opening with no suitable fall protection.

➎ Only use suitable and safe WAH equipment e.g. ladder, scaffold, boom lift.

D) WORKING AT HEIGHT (WAH)

-

NOTE : Please indicate NA if any item in this section is not applicable or not inspected during the MSOT.

-

1. Is Technician required to work at height at this site? <br><br>E.g. change glue board at the roof void, termite inspection at roof void, service air freshener/ILT on ladder.

-

Please specify the type of WAH and the height:

-

2. Is Technician trained on the work at height? <br><br>E.g. training on ladder use, roof void safety, crawl board use, operate boom lift, scissor lift, use of harness & lifeline

-

Please specify the type of training.

-

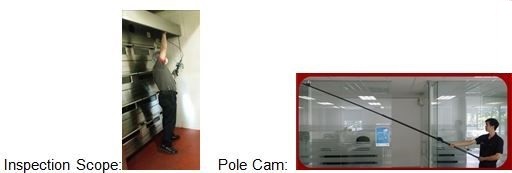

3. Is there other safer way to do the work without WAH? <br><br>E.g. using a long pole camera, inspection scope, rodent camera or treatment from the ground. DO NOT use wooden plank, chair, table, and other tool that are not designed to support WAH.

-

-

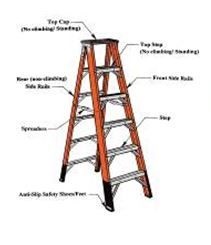

4. If stepladder is used, is it of the right height (top 2 rungs must not be used) and in good condition? There is label on the ladder indicating the Safe Working Load (SWL) e.g. SWL 150kg?

-

➊ Right ladder height = Top 2 rungs must not be used

➋ Good ladder conditions = have Safe Working Load label, no missing/ damaged rubber base, spreader, rails, rungs

➌ For entry into roof void = Stepladder should not be used. Only leaning ladder that can extend 1meter through the roof void opening shall be used. -

5. If technician is using a ladder :<br><br>• Is the ladder laid on even ground? <br>• Is technician maintaining 3 points of contact with ladder and has the front of his body facing the ladder?

-

➊ Correct position on ladder = front of body facing ladder.

➋ No placing of ladder on staircase/ slope/ uneven floor.

➌ Maintain 3-point contact on ladder -

6. Air-freshener (AF) / Fly Killer Dispenser Unit :<br><br>• installed not more than 2 meter from the ground, the maximum allowable height (as per RI Policy), to avoid the need for ladder/ to minimize WAH risks and enable Technician to use the appropriate ladder available from RI.<br><br>• not installed directly above areas with human traffic/ activities e.g. above doorways, seating areas, toilet seats, diaper changing areas, so as to minimize the risks of hit by falling units.

-

7. Bait Stations and Fly Traps :<br><br>• not installed at height where access is unsafe or obstructed, causing risks of falling from height e.g. near unguarded/ open edge of a platform or wall.

E) SLIP, TRIP & FALL, MOVING VEHICLE AND OTHER RISKS

-

NOTE : Please indicate NA if following items are not applicable or not inspected during the MSOT.

-

1. Are bait stations, fly trap installed at:<br><br>• safe to access locations, that avoid/ minimize slip , trip and fall risks? <br>E.g. as far as practicable, avoid installing on slope, avoid areas near open drain, area with narrow access or without a proper access path

-

2. Are bait stations, fly trap installed at:<br><br>• safe distance from moving vehicles, moving machinery and electrical hazards? <br>E.g. at a safe distance from moving vehicles at carpark/ loading bay, forklift at store, away from opening/ closing door, away from window which maybe an overhead hazard, away from electrical cable/ panel.<br>

F) DRIVING AND PEDESTRIAN SAFETY

-

NOTE : Please indicate NA if following items are not applicable or not inspected during the MSOT.

-

1. Can Technician explain the 5 SHE Golden Rules on “Driving At Work”?

-

ANSWER :

➊ Only drive your vehicle if it is safe and legally roadworthy.

➋ Do not use hand-held mobile phones / devices whilst driving.

➌ Watch your speed and always take into account road and traffic conditions.

➍ Seatbelts must be worn by drivers and passengers.

➎ Always maintain a safe stopping distance from the vehicle in front of you. -

2. Does Technician has a valid driving license? Take picture of the license.

-

3. Is Technician (who is driving the vehicle) the authorized driver appointed by RI to drive this vehicle?

-

4. Is Technician (authorized driver) provided with the Company Vehicle Handbook and has been briefed on the handbook by his supervisor/ manager/ SHE personnel?

-

5. Is service vehicle in good condition? Take picture of vehicle & license plate.<br><br>Look out for any worn out tire, dent on vehicle body, cracked mirror, glass etc. Get feedback from technician if vehicle functions are in good working order e.g. brake, lights, reversing sensor, seat belt.

-

6. Are seat belts easily accessible and in good condition? Take a picture.

-

7. Is service vehicle equipped with the following emergency response equipment and these are in good conditions?<br><br>• Extinguisher, First Aid Kit, High Visibility Vest, Safety Cones, Hazard Triangle

-

8. Is Technician wearing high visibility vest, or using safety cones while loading/ unloading materials/ doing preparatory work at his vehicle in areas with moving vehicle risks?

-

9. Is Technician wearing high visibility vest while working in areas with moving vehicles such as carpark, road side, loading bay, warehouse with forklift?

G) EMPLOYEE INDUCTION AND CONSULTATION

-

1. Did Technician complete SHE Induction Training conducted by his / her supervisor/ manager/ SHE personnel when he/ she first joined RI?

-

2. Consultation with Employee Any SHE concern/ area of improvements to suggest for your work? If none, please indicate NIL below.

What To Look Out For In A Branch

-

NOTE : Section H to K criteria are to be used to evaluate a Branch.

INSTRUCTION:

Please choose -

✔ “Good Condition/ Good Practice” or “Yes”

X “Not in Good Condition/ Unsafe Practice” or “No”

P “Partially Good / Partial Understanding”

✱ Copy of MSOT report should be forwarded to the Country SHE Manager.

H) SHE Golden Rules Training At Branch

-

1. Is SHE Golden Rules training being conducted for all employees at the branch?

-

2. Is the attendance sheet for the same is kept for future reference?

I) SRA Implementation At The Branch

-

1. Is the branch undertaking SRA (Site Risk Assessment)?<br>Sample check 3 SRA reports from the branch.

-

2. Is the SRA being shared by CSE (Customer Sales Executive) with OE (Operations Executive), who has to communicate the SRA information to the technicians?

J) Management of PPE (Personal Protective Equipment)

-

1. Is PPE pre-use inspection being carried out by technicians?<br>Verify by interviewing 1 or 2 technicians.

-

2. Is half-yearly PPE inspection being carried out by Branch SHE Coordinator?

-

3. Are the records for the half-yearly PPE inspection maintained? <br>Verify PPE half-yearly inspection reports for last 2 months from BM/ Branch SHE Coordinator.

-

4. Are PPE Issue Records maintained at the branch store?<br>Verify PPE Issue Records from BM/ Branch SHE Coordinator/ Store Supervisor.

K) Management of Driving And Motorbike Riding Safety

-

1. Are all employees being trained for safe driving, using the following materials and training attendance recorded?<br>• RI motorbike riding safety video<br>Verify training attendance record on the above.

-

2. Are vehicle safety inspections for all vehicles being carried out every quarterly? <br>Ask for and sample check last 2 months’ Monthly Vehicle Safety Inspection Reports from BM/ Branch SHE Coordinator.

-

3. Is a Summary List of Drivers & Motorbike Riders (consisting of driving license numbers & expiry dates) maintained and regularly updated by a designated person at the branch?<br>Check “Summary List of Drivers & Motorbike Riders” from BM / Branch SHE Coordinator.

-

4. Any driving license/ motorbike license expired from the summary list in point 3? <br>Are actions taken/ in progress to have the license renewed?<br>Capture photo of the Driver/ Rider’s Summary List with the names of the staff with expired licenses, and attach to this MSOT iAuditor report.

-

5. Are the following documents being maintained in each Employee File? <br>Sample check for 3 Employee Files, from the BM/ Branch SHE Coordinator.<br>• Driving License<br>• RC Book<br>• Insurance of vehicle<br>• Road Tax<br>• Safe Driving Declaration ~ signed by driver/ rider<br>• Authorization To Drive Letter (RI provided format) ~ signed by the owner of the vehicle, if vehicle is not registered directly under the staff/ driver’s name. (Employees driving vehicle registered on Father, Mother, Brother, Wife ....)

Signature

SIGNATURE

-

Signature Of Employee

-

Date for Signature Of Employee

-

Signature Of Branch Manager

-

Date for Signature Of Branch Manager

-

Signature Of Leader / Assessor

-

Date for Signature Of Leader / Assessor