Rev (08/24)

-

Shift

-

Conducted on

-

INSPECTED BY

-

Work Order NO:

10053000006650

-

Axle serial No

-

S.NO 1

-

S.NO 1

-

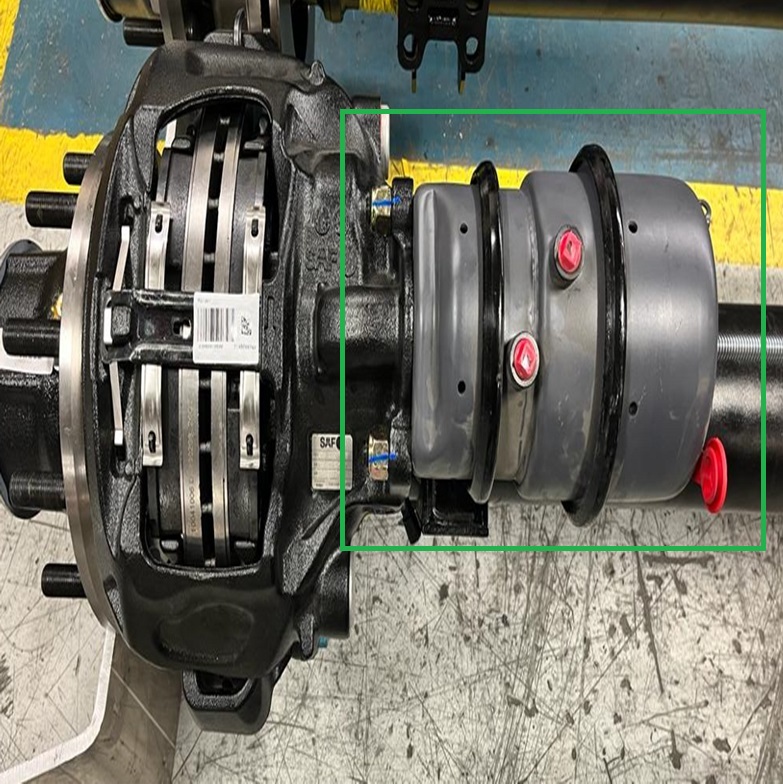

Example - BRAKE CHAMBER (Top mount orientate air hose fitting Away from the Axle tube.)

-

BRAKE CHAMBER (Top mount orientate air hose fitting Away from the Axle tube.)

-

Left Side Picture

-

Right Side Picture

-

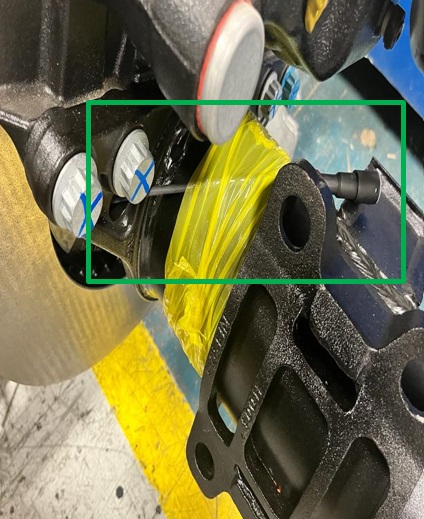

Example - ABS Sensor has been installed correctly, wire is orientated toward top of axle. Also ensure that ABS sensor is shrined wrapped to axle

-

ABS Sensor has been installed correctly, wire is orientated toward top of axle. Also ensure that ABS sensor is shrined wrapped to axle

-

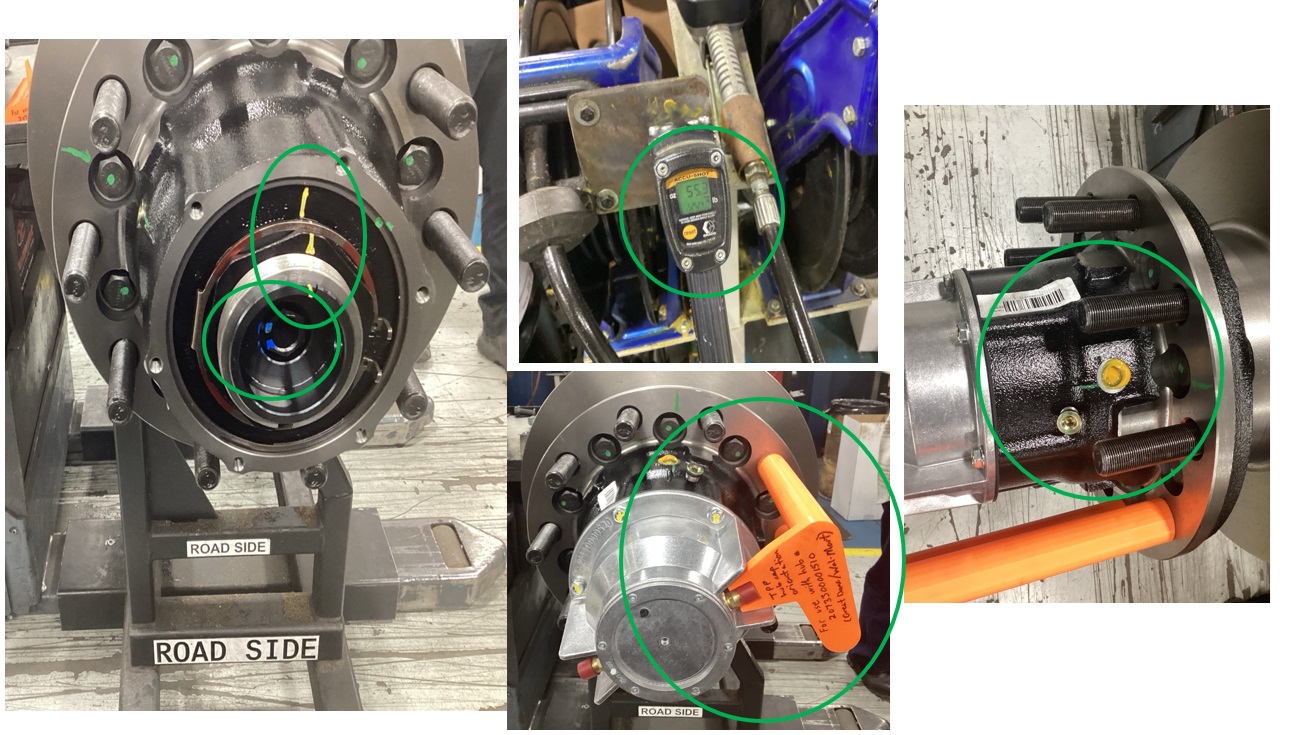

Example -Torque Mark verification : Grease Cap, Hubcap, Caliper Bolts, Brake Chamber

-

All Torque Bolts Have Witness Marks : Grease Cap, Hubcap, Caliper Bolts, Brake Chamber

-

HUB- Ensure the correct hub has been installed. - Verify the BOM

-

Example -- SAP Picture Verification 1 to 5

-

SAP Picture Verification 1 - Spindle torque mark ( 2 Pictures -Curbside and Roadside)

-

SAP Picture Verification 2 - TPP plug to be located between 11 and 1 o’clock positions of the axle when mounted on truck. Use Pictures. Roadside=9 O'clock Curbside=3 O'clock (ESM-060) -( 2 Pictures -Curbside and Roadside)

-

SAP Picture Verification 3 - Presence of grease - ( 2 Pictures -Curbside and Roadside)

-

SAP Picture Verification 4 - Grease gun showing the dispensed amount - ( 2 Pictures -Curbside and Roadside)

-

SAP Picture Verification 5- TPP HUB CAP - Please verify the SAP images to ensure that the TPP hub cap is properly clocked. - ( 2 Pictures -Curbside and Roadside)

-

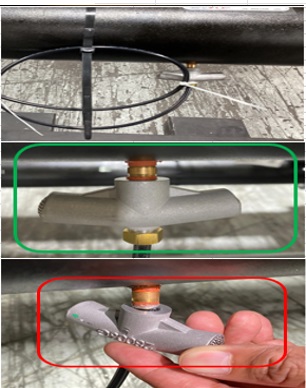

Example -CENTER VENT (TPP) - Ensure that the center vent on the axle beam is installed and free of any damage.

-

CENTER VENT (TPP) - Ensure that the center vent on the axle beam is installed and free of any damage.

-

S.NO 2

-

S.NO 2

-

Example - BRAKE CHAMBER (Top mount orientate air hose fitting Away from the Axle tube.)

-

BRAKE CHAMBER (Top mount orientate air hose fitting Away from the Axle tube.)

-

Left Side Picture

-

Right Side Picture

-

Example - ABS Sensor has been installed correctly, wire is orientated toward top of axle. Also ensure that ABS sensor is shrined wrapped to axle

-

ABS Sensor has been installed correctly, wire is orientated toward top of axle. Also ensure that ABS sensor is shrined wrapped to axle

-

Example -Torque Mark verification : Grease Cap, Hubcap, Caliper Bolts, Brake Chamber

-

All Torque Bolts Have Witness Marks : Grease Cap, Hubcap, Caliper Bolts, Brake Chamber

-

HUB- Ensure the correct hub has been installed. - Verify the BOM

-

Example -- SAP Picture Verification 1 to 5

-

SAP Picture Verification 1 - Spindle torque mark ( 2 Pictures -Curbside and Roadside)

-

SAP Picture Verification 2 - TPP plug to be located between 11 and 1 o’clock positions of the axle when mounted on truck. Use Pictures. Roadside=9 O'clock Curbside=3 O'clock (ESM-060) -( 2 Pictures -Curbside and Roadside)

-

SAP Picture Verification 3 - Presence of grease - ( 2 Pictures -Curbside and Roadside)

-

SAP Picture Verification 4 - Grease gun showing the dispensed amount - ( 2 Pictures -Curbside and Roadside)

-

SAP Picture Verification 5- TPP HUB CAP - Please verify the SAP images to ensure that the TPP hub cap is properly clocked. - ( 2 Pictures -Curbside and Roadside)

-

Example -CENTER VENT (TPP) - Ensure that the center vent on the axle beam is installed and free of any damage.

-

CENTER VENT (TPP) - Ensure that the center vent on the axle beam is installed and free of any damage.

-

S.NO 3

-

S.NO 3

-

Example - BRAKE CHAMBER (Top mount orientate air hose fitting Away from the Axle tube.)

-

BRAKE CHAMBER (Top mount orientate air hose fitting Away from the Axle tube.)

-

Left Side Picture

-

Right Side Picture

-

Example - ABS Sensor has been installed correctly, wire is orientated toward top of axle. Also ensure that ABS sensor is shrined wrapped to axle

-

ABS Sensor has been installed correctly, wire is orientated toward top of axle. Also ensure that ABS sensor is shrined wrapped to axle

-

Example -Torque Mark verification : Grease Cap, Hubcap, Caliper Bolts, Brake Chamber

-

All Torque Bolts Have Witness Marks : Grease Cap, Hubcap, Caliper Bolts, Brake Chamber

-

HUB- Ensure the correct hub has been installed. - Verify the BOM

-

Example -- SAP Picture Verification 1 to 5

-

SAP Picture Verification 1 - Spindle torque mark ( 2 Pictures -Curbside and Roadside)

-

SAP Picture Verification 2 - TPP plug to be located between 11 and 1 o’clock positions of the axle when mounted on truck. Use Pictures. Roadside=9 O'clock Curbside=3 O'clock (ESM-060) -( 2 Pictures -Curbside and Roadside)

-

SAP Picture Verification 3 - Presence of grease - ( 2 Pictures -Curbside and Roadside)

-

SAP Picture Verification 4 - Grease gun showing the dispensed amount - ( 2 Pictures -Curbside and Roadside)

-

SAP Picture Verification 5- TPP HUB CAP - Please verify the SAP images to ensure that the TPP hub cap is properly clocked. - ( 2 Pictures -Curbside and Roadside)

-

Example -CENTER VENT (TPP) - Ensure that the center vent on the axle beam is installed and free of any damage.

-

CENTER VENT (TPP) - Ensure that the center vent on the axle beam is installed and free of any damage.

-

S.NO 4

-

S.NO 4

-

Example - BRAKE CHAMBER (Top mount orientate air hose fitting Away from the Axle tube.)

-

BRAKE CHAMBER (Top mount orientate air hose fitting Away from the Axle tube.)

-

Left Side Picture

-

Right Side Picture

-

Example - ABS Sensor has been installed correctly, wire is orientated toward top of axle. Also ensure that ABS sensor is shrined wrapped to axle

-

ABS Sensor has been installed correctly, wire is orientated toward top of axle. Also ensure that ABS sensor is shrined wrapped to axle

-

Example -Torque Mark verification : Grease Cap, Hubcap, Caliper Bolts, Brake Chamber

-

All Torque Bolts Have Witness Marks : Grease Cap, Hubcap, Caliper Bolts, Brake Chamber

-

HUB- Ensure the correct hub has been installed. - Verify the BOM

-

Example -- SAP Picture Verification 1 to 5

-

SAP Picture Verification 1 - Spindle torque mark ( 2 Pictures -Curbside and Roadside)

-

SAP Picture Verification 2 - TPP plug to be located between 11 and 1 o’clock positions of the axle when mounted on truck. Use Pictures. Roadside=9 O'clock Curbside=3 O'clock (ESM-060) -( 2 Pictures -Curbside and Roadside)

-

SAP Picture Verification 3 - Presence of grease - ( 2 Pictures -Curbside and Roadside)

-

SAP Picture Verification 4 - Grease gun showing the dispensed amount - ( 2 Pictures -Curbside and Roadside)

-

SAP Picture Verification 5- TPP HUB CAP - Please verify the SAP images to ensure that the TPP hub cap is properly clocked. - ( 2 Pictures -Curbside and Roadside)

-

Example -CENTER VENT (TPP) - Ensure that the center vent on the axle beam is installed and free of any damage.

-

CENTER VENT (TPP) - Ensure that the center vent on the axle beam is installed and free of any damage.

-

S.NO 5

-

S.NO 5

-

Example - BRAKE CHAMBER (Top mount orientate air hose fitting Away from the Axle tube.)

-

BRAKE CHAMBER (Top mount orientate air hose fitting Away from the Axle tube.)

-

Left Side Picture

-

Right Side Picture

-

Example - ABS Sensor has been installed correctly, wire is orientated toward top of axle. Also ensure that ABS sensor is shrined wrapped to axle

-

ABS Sensor has been installed correctly, wire is orientated toward top of axle. Also ensure that ABS sensor is shrined wrapped to axle

-

Example -Torque Mark verification : Grease Cap, Hubcap, Caliper Bolts, Brake Chamber

-

All Torque Bolts Have Witness Marks : Grease Cap, Hubcap, Caliper Bolts, Brake Chamber

-

HUB- Ensure the correct hub has been installed. - Verify the BOM

-

Example -- SAP Picture Verification 1 to 5

-

SAP Picture Verification 1 - Spindle torque mark ( 2 Pictures -Curbside and Roadside)

-

SAP Picture Verification 2 - TPP plug to be located between 11 and 1 o’clock positions of the axle when mounted on truck. Use Pictures. Roadside=9 O'clock Curbside=3 O'clock (ESM-060) -( 2 Pictures -Curbside and Roadside)

-

SAP Picture Verification 3 - Presence of grease - ( 2 Pictures -Curbside and Roadside)

-

SAP Picture Verification 4 - Grease gun showing the dispensed amount - ( 2 Pictures -Curbside and Roadside)

-

SAP Picture Verification 5- TPP HUB CAP - Please verify the SAP images to ensure that the TPP hub cap is properly clocked. - ( 2 Pictures -Curbside and Roadside)

-

Example -CENTER VENT (TPP) - Ensure that the center vent on the axle beam is installed and free of any damage.

-

CENTER VENT (TPP) - Ensure that the center vent on the axle beam is installed and free of any damage.

-

Example - SKIDDING- Ensure axles are skidded safely and are secured to the metal skids using nuts. (18 Nuts/Side)

-

SKIDDING- Ensure axles are skidded safely and are secured to the metal skids using nuts. (18 Nuts/Side)

-

ROADSIDE PICTURE

-

CURBSIDE PICTURE

-

Example - Ensure that the master label on every good axle is stamped with the NLPC green stamp.(Ensure the correct date on the stamp)

-

Ensure that the master label every good axle is stamped with the NLPC green stamp.(Ensure the correct date on the stamp)

-

Example - Ensure the warning label is attached above the TPP vent on the axles located in the center row of the skid (Both sides of the skid)

-

Ensure the warning label is attached above the TPP vent on the axles located in the center row of the skid (Both sides of the skid)

-

Please inform the supervisor that the axle has been green-tagged and is now ready to be moved to the shipping from the NLPC area.