Title Page

-

Conducted on

-

Prepared by

-

Subcontractor Company

- AES

- SMS Ltd (Smarter Metering Services)

- SMS Plc

- Energise

- Providor

- EON

-

Engineer Name

- Alexander Bowie

- Ben Sutton

- Brian Fitzpatrick

- Broderick Urquhart

- Billy Joe-Nash

- Charles Marful

- David Cockman

- David Ogun

- Elvis Yzeiri

- Emil Hussain

- Farid Azimzadeh

- Greg Ryan

- Gregory Thorpe

- James Thirkell

- Jamie Cook

- Jamie Lee Barron

- Jamie Lee Brooks

- Jerrod Doras

- Joseph Turner

- Kevin Wraith

- Lee Hockley

- Lee Rees

- Martin Baxter

- Maxwell Onyeagwam

- Muhammed Rakha

- Neil Culley

- Paulo Caixerio

- Patrick Chakanyuka

- Peter Corleys

- Ramunas Valasinas

- Rebecca Middleton

- Richard Adam

- Samuel Cotgrove

- Simon Rampley

- Stephen Sivathasan

- Timothy Hett

- Vitaliy Bohutskyy

- Adam Berry

- lee bunting

- Blerim Hajdari

- Carlos Arruda

- Greg Laider

- Micheal Sulston

- Muhammed Aqeel

- Patrick campell

- Phil smith

- Shakil Ali

- Tomas Buksar

- Yasir Mahmood

- Raqib Mohammed

- Adam boyce

- Josh Bell

- Dean smith

- Gavin Able

- Angus Anderson

- Chris Pike

- Crispin Abudo

- Darran Page

- John Hustler

- Keith Sharpe

- Marcus Carpenter

- Thomas Bett

- Aston kelly smith

- John Moulton

- Rhys Morgan

- Richard Miah

- Robert Radford

- Tom Wansbrough

- Tom Andrews

- Gareth James

- Ian Aspland

- Joe Southgate

- Lee Hales

- Mahesh Versani

- Matt Wright

- Nathan Wallace

- Owen Rixon

- Simon Elliot

- Steven Davies

- Stuart Davies

- Daljoet Jawanda

- Richard Wiecko

- James Horton

- Kyle Nicholas

- Faried Khalaileh

- Richard Rowden

- Steve Winson

- Ben Billing

- Iain Kennedy

- Lee Holland

- Sam Neath

- Banh Minh

- Robinson Neil

- Fallon Jordan

- Gilliat Keigan

- Ratcliffe Stephen

- Colleran Tom

- Williams Phil

- Reville Stuart

- Reed Andy

- Parnham Paul

- Butterton Joshua

- Hand Edward

- Flaherty Joanne

- Heywood Ben

- Prior Gary

- Bartle Andrew

- Gleadhall Kris

- Douglas Robert

- Carrick Glenn

- Whitehead Steven

- Webster Sam

- Pyrah Andy

- Bradshaw Jamie

- Sallans Chris

- Robinson Daniel

- Steel Jamie

- Davine David

- Rankin Martin

- Taylor Carl

- Ogden Ben

- Whitehead Ian

- Leeks Simon

- Speed Mark

- Foster Phil

- Eddon Brian

- Smith Richard

- Crawford Ethan

- Hussain Iqbal Mohammed

- Leahy Daniel

- Hampsey Ian

- Fairhurst Jac

- Reynolds Max

- Cosgrove Shaun

- Foster Carl

- Thomas Sheman

- Grace Ian

- Simmonds Kevin

- Mongomery David

- Cheeseman Ian

- Challinor Joshua

- Dickinson Chris

- Reay Michael

- Kelly Leon

- Barratt James

- Sayles Andrew

- Abdulla Altin

- Stokoe John

- Crompton Alan

- Tonge Andy

- Irwin Barrie

- Kearns Barry

- Patel Bhupendra

- o'Neil Callum

- Backland Carl

- Shannon Chris

- Fowler Colin

- Dandy Craig

- McGlone Danile

- Wallis Darren

- Melvin David

- Woods David

- Member Fayazz

- Flight Frank

- Horrocks Gary

- Gunn Graeme

- Pollard Graeme

- Barber Hannah

- Wilkes Ian

- Ali Ikram

- Glover Jack

- Scully Jack

- McGregor Jacob

- Oldfield Jake

- Hilton James

- Tunnicliffe James

- Hulme Jamie

- Hussain Javaid

- Simpson John

- Burgess Jordan

- Yates Judd

- Desai Junaid

- Cox Kev

- Armstrong Marc

- Llewellyn Mark

- Williamson Mark

- Paisey Matt

- Dowling Maurice

- Thompson Michael

- Foster Michelle Dixon

- Patel Mohammed

- Haq Mohammed

- Duggan Neil

- Quinn Nicky

- Owen Oliver

- Roberts Paul

- Smith Peter

- Taylor Peter

- Ludlam Phil

- Graham Richard

- Clarke Ryan Salked

- Ennis Sarah

- Atkinson Sean

- Davies Shane

- Widows Sofie

- Sweeney Ste

- Carter Stephen

- Harding Stephen

- Williams Stephen

- Mcintosh Stewart

- Aziz Tariq

- Wignall Tom

- Brown Warren

- Nazim Abbas

- Malik Akhmed

- Ali Balal

- Blendal Bernard

- Pyle Brandon

- Aston Callum

- Zannetou Chris

- Donnell Christian

- King Darren

- McIntosh Delroy

- Karem Devinder

- Singh Gurwinder

- Debbech Hamdi

- Waraich Hamzah

- Wilkins James

- Hand Jason

- Swingler John

- Derby Kevin

- Edwards Liam

- Elliott Luke

- Edensor Martyn

- Basharit Mohammed

- Mohsin Muhammed

- Jones Nathan

- Mohammed Qasim

- Alguwair Rashad

- Razaq Rizwan

- Mahmood Sajid

- Hall Sam

- Thomas Simon

- Downey Terence

- Vorajee Usman

- Khan Waleed

- Glenn Wayne

- Yasin Zabair

- Steve Smith

- Richard Beasley

- Darren Loveday

- Gavin Francis

- Glen Knight

- Luke Fitzpatrick

- Lee Hopkins

- Saeed Ahmad

- Peter Dempsey

- Lee Sparey

- Steve Watson

- Paul Burnham

- Nathan Barrow

- Ben Gaine

- Craig Butler

- Matthew Channon

- Cleves Graham

- Davies Joe

- Ram Karavadra

- Haydn Thomas

- Peter Lowery

- Alisdair Reeves

- Andrew Richards

- Anthony Waite

- Ryan Adams

- Daniel Phillips

- Naeem Hashmi

- Brian Shee

- Abu Chowdhury

- Adam Edwards

- Kamaljit Dhillon

- Steven Champion

- Ashley Mullender

- Ishtiaq Ahmed

- Mohammed Balal

- Troy Simmons

- Hailee Atack

- Martin Meads

- Naseem Ahmed

- Nathan Walker

- Jonathon Hughes

- Joseph McCann

- Richard Pain

- Darren Kerr

- Scott Maxted

- Nirosh Patabendige

- Andrew Stones

- Christopher Martin

- David Harding

- Lance Buckle

- Lee Bentham

- Laura Millerchip

- Gemma Campbell

- Connor Owen

- Paul Dalgarno

- Adam Vine

- Guy Stratton

- Chris Pastore

- James Gardner

-

Site address

-

Please provide the full OES reference (i.e OCTO/00012345)

-

MPAN

-

Engineer competency certificate present

-

What is the expiry date

-

Please take a picture of the certificate

-

Contact engineers manager for further information and then contact compliance for instruction on how to proceed

Doorstep Protocol

-

Did the engineer arrive at the appointed time?

-

What time did the engineer arrive?

-

Did the engineer call ahead and inform the customer of the late arrival?

-

CAT 3 E44 SMICoP/door step protocol not applied appropriately

-

Was the engineer suitably attired?

-

Does the engineer have the appropriate attire on their vehicle?

-

CAT 1 E12 Appropriate PPE not worn

-

CAT 2 EX2 Miscellaneous - supporting notes required

-

Did the engineer identify themselves and advise on the role of any other attendees?

-

CAT 3 E44 SMICoP/door step protocol not applied appropriately

-

Did the engineer show their ID card?

-

CAT 3 E44 SMICoP/door step protocol not applied appropriately

-

Did the engineer explain the purpose of the visit?

-

CAT 3 E44 SMICoP/door step protocol not applied appropriately

-

Did the engineer explain to the customer a site inspection would be performed prior to work proceeding?

-

CAT 3 E44 SMICoP/door step protocol not applied appropriately

-

Did the engineer advise the customer the supplier they are working on behalf of?

-

CAT 3 E44 SMICoP/door step protocol not applied appropriately

-

Where more than one engineer (persons) attended site, did the engineer notify the customer how many representatives would be attending in advance of the site visit?

-

CAT 3 E44 SMICoP/door step protocol not applied appropriately

-

Is the customer a resident in sheltered accommodation?

-

Did the engineer gain approval from the warden/person in authority before approaching the resident?

-

CAT 3 E44 SMICoP/door step protocol not applied appropriately

-

Did the engineer apply COVID protocol?

-

CAT1

Technical Inspection

-

Please indicate installation type?

-

Meter location

-

Has the engineer visually inspected the meter position for hazards/risks?

-

CAT1

-

Has engineer confirmed the meter details match job notes?

-

CAT2 E33 Data incorrectly submitted

-

Did the engineer inspect the cut-out and metering equipment for signs of distress and/or tampering?

-

CAT1 E10 Risk assessment not adequate - PRE and/or POST metering works

-

Has the engineer correctly identified any service termination issues (cut-out)?

-

CAT1 E8 DNO A code not applied correctly or actioned; CAT2 DNO B code not applied correctly or actioned; CAT3 DNO C code not applied correctly or actioned

-

Can the installation safely continue?

-

Continue inspection

Testing and Isolation

-

Did the engineer prove not live on extraneous metal work, exposed cabling/conductors and cut-out casing?

-

CAT1 E11 Testing not conducted correctly - PRE and/or POST metering works

-

Has the engineer used a plug-in tester at an appropriate socket?

-

CAT1 E11 Testing not conducted correctly - PRE and/or POST metering works

-

Please provide details

-

Has a flick test on three phase equipment been performed?

-

CAT1 E11 Testing not conducted correctly - PRE and/or POST metering works

-

Has the engineer advised the customer to switch off electrical appliances and sensitive equipment?

-

Failed to instruct and not picked up on prompt - CAT1 E7 Engineer worked out of scope/Engineer not applying competence

-

CAT3 E44 SMICoP/door step protocol not applied appropriately

-

Has the engineer isolated the mains correctly (CCU/PV etc)?

-

CAT1

-

Has the engineer confirmed polarity at the metering equipment?

-

CAT1 E11 Testing not conducted correctly - PRE and/or POST metering works

-

Has the engineer confirmed supply at the metering equipment?

-

CAT1 E11 Testing not conducted correctly - PRE and/or POST metering works

-

Has the engineer confirmed phase rotation at the metering equipment?

-

CAT1 E11 Testing not conducted correctly - PRE and/or POST metering works

-

Has the engineer correctly and safely withdrawn the cut-out fuse/s?

-

CAT1

-

Has the engineer confirmed polarity at the cut-out?

-

CAT1 E11 Testing not conducted correctly - PRE and/or POST metering works

-

Has the engineer confirmed supply at the cut-out?

-

CAT1 E11 Testing not conducted correctly - PRE and/or POST metering works

-

Has the engineer confirmed phase rotation at the cut-out?

-

CAT1 E11 Testing not conducted correctly - PRE and/or POST metering works

-

Has the engineer applied the appropriate shrouding?

-

CAT1 E13 Shrouding not applied correctly

-

Did the engineer apply the appropriate PPE during testing and isolation?

-

CAT1

-

What is the earthing system?

-

Can the engineer correctly identify the earthing system?

-

CAT1 E7 Engineer worked out of scope/Engineer not applying competence

-

Has the engineer correctly identified any service termination issues (cut-out)?

-

CAT1 E8 DNO A code not applied correctly or actioned; CAT2 DNO B code not applied correctly or actioned; CAT3 DNO C code not applied correctly or actioned

-

Can the installation safely continue?

-

Continue inspection

Exchange processes

-

Has the engineer proved all terminations 'not live' before removing cabling?

-

CAT1 E11 Testing not conducted correctly - PRE and/or POST metering works

-

Has the engineer checked the rating and condition of the main fuse/s?

-

CAT2 E31 Fuse rating/cable size not adequate

-

Is the cable sizing suitable for the installation?

-

CAT2 E31 Fuse rating/cable size not adequate

-

Has the metering equipment been suitably and safely installed?

-

CAT1

-

CAT2

-

CAT3

-

Has the cabling been adequately installed?

-

CAT1

-

CAT2

-

CAT3

-

Are all terminals tight?

-

Dependent on rotation:

-

CAT1 E4 Loose terminations- greater than 360° rotation on any termination

-

CAT2 E30 Terminations not adequately tightened- rotation on any terminal screw between 180° and 360° (half turn)

-

Has the engineer marked all cables as per COP?

-

CAT2 E29 Polarity markings and/or indicators incorrect/tails not marked

-

Did the engineer apply the appropriate PPE during the installation?

-

CAT1

Testing and Energisation

-

Has the engineer confirmed polarity at the cut-out?

-

CAT1 E11 Testing not conducted correctly - PRE and/or POST metering works

-

Has the engineer confirmed supply at the cut-out?

-

CAT1 E11 Testing not conducted correctly - PRE and/or POST metering works

-

Has the engineer confirmed phase rotation at the cut-out?

-

CAT1 E11 Testing not conducted correctly - PRE and/or POST metering works

-

Has the engineer correctly and safely re-inserted the cut-out fuse/s?

-

CAT1

-

Has the engineer confirmed polarity at the metering equipment?

-

CAT1 E11 Testing not conducted correctly - PRE and/or POST metering works

-

Has the engineer confirmed supply at the metering equipment?

-

CAT1 E11 Testing not conducted correctly - PRE and/or POST metering works

-

Has the engineer confirmed phase rotation at the metering equipment?

-

CAT1 E11 Testing not conducted correctly - PRE and/or POST metering works

-

Has the engineer switched the mains back on correctly (CCU/PV etc)?

-

CAT1

-

Has the engineer used a plug-in tester at an appropriate socket?

-

CAT1 E11 Testing not conducted correctly - PRE and/or POST metering works

-

Has a flick test on three phase equipment been performed?

-

CAT1 E11 Testing not conducted correctly - PRE and/or POST metering works

-

Did the engineer apply the appropriate PPE during testing and energisation?

-

CAT1

-

Has the engineer correctly identified any service termination issues (cut-out)?

-

CAT1 E8 DNO A code not applied correctly or actioned; CAT2 DNO B code not applied correctly or actioned; CAT3 DNO C code not applied correctly or actioned

-

Did the engineer prove not live on extraneous metal work?

-

CAT1 E11 Testing not conducted correctly - PRE and/or POST metering works

Customer focus

-

Did the engineer complete the installation with the customer, carer or responsible person present?

-

CAT3 E44 SMICoP/door step protocol not applied appropriately

-

Did the engineer experience issues communicating with the customer?

-

Did the engineer follow the correct process to address the communication issue?

-

CAT3 E44 SMICoP/door step protocol not applied appropriately

-

Did the engineer identify any specific requirements to support the customer?

-

Did the engineer follow the correct process to provide the correct support?

-

CAT3 E44 SMICoP/door step protocol not applied appropriately

-

Did the comms hub/meter require relocating/reconfiguring?

-

Did the engineer advise the customer and gain permission to perform the required works?

-

CAT3 E44 SMICoP/door step protocol not applied appropriately

-

Did the engineer correctly commission the meter?

-

CAT3 E44 SMICoP/door step protocol not applied appropriately

-

Did the engineer demonstrate how to use the metering equipment?

-

CAT3 E44 SMICoP/door step protocol not applied appropriately

-

Where supply was impacted and the customer had specific needs (vulnerability/medical needs etc). Did the engineer use reasonable endeavours to minimise the impact?

-

CAT3 E44 SMICoP/door step protocol not applied appropriately

-

New Meter Serial Number

Completion processes

-

Did the engineer inspect the customer's installation for signs of distress, faults and condition?

-

CAT1 E10 Risk assessment not adequate - PRE and/or POST metering works

-

Has the engineer correctly identified any issues with the customer's installation?

-

CAT1

-

CAT2

-

CAT3

-

Has the engineer left a warning notice with the customer?

-

CAT3 E45 Metering installation notices and labelling incomplete/not applied

-

Has the engineer correctly sealed the installation?

-

One or more points not sealed - CAT2 E27 Available sealing point/s not sealed

-

One or more seals mis-crimped or illegible - CAT3 E40 Seal/s not legible

-

Please provide the engineers sealing plier number including identifier letters. (i.e. MOM 001)

-

Has the engineer applied the correct labelling to the installation?

-

CAT3 E45 Metering installation notices and labelling incomplete/not applied

-

Has the engineer left the appropriate paperwork/leaflets with the customer?

-

CAT3 E45 Metering installation notices and labelling incomplete/not applied

-

Has all company waste been removed?

-

CAT3 E42 Company waste left on site

-

If the installation was incomplete has the site been left in a safe state?

-

CAT1

-

Where the engineer identified a fault with the installation/metering equipment, did they notify the customer and inform them of the appropriate next steps?

-

CAT3 E44 SMICoP/door step protocol not applied appropriately

-

Did the customer/responsible person raise a complaint during the site visit?

-

Did the engineer deal with the complaint appropriately and direct the customer to the supplier where necessary?

-

CAT3 E44 SMICoP/door step protocol not applied appropriately

-

Did the engineer provide guidance on energy efficiency and or dangers of carbon monoxide poisoning?

-

CAT3 E44 SMICoP/door step protocol not applied appropriately

-

Did the engineer direct the customer to where energy efficiency guidance can be found?

-

CAT3 E44 SMICoP/door step protocol not applied appropriately

-

Has handheld been completed correctly?

-

CAT2 E33 Data incorrectly submitted

-

CAT3 E47 Handheld unit incorrectly used

-

Has the engineer taken the required photographs?

-

CAT3 E46 Photographs missing or inadequate

-

Did the engineer leave the site as found?

-

Provide details

Audit Review

-

Audit outcome

-

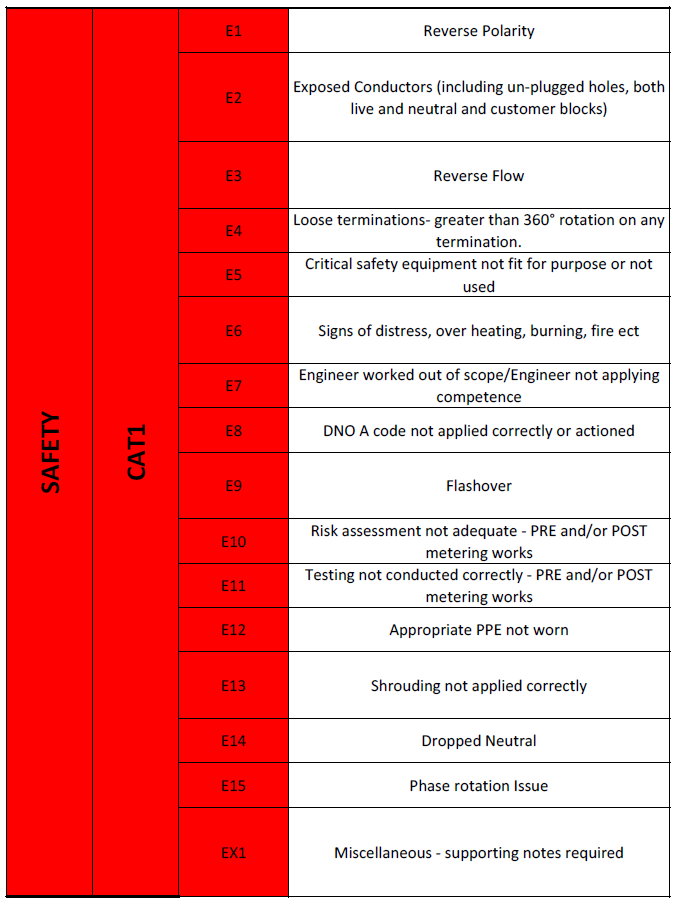

CAT1 issue/s identified?

-

-

Select all that apply (include any selected earlier)

- E1

- E2

- E3

- E4

- E5

- E6

- E7

- E8

- E9

- E10

- E11

- E12

- E13

- E14

- E15

- EX1

-

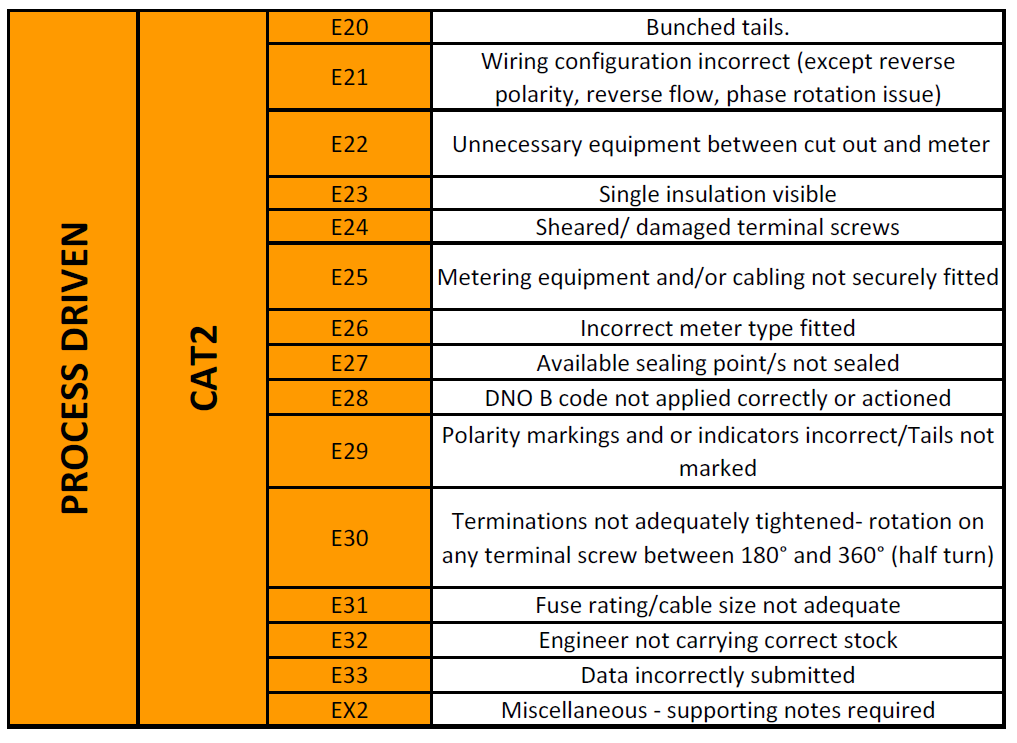

CAT2 issue/s identified?

-

-

Select all that apply (include any selected earlier)

- E20

- E21

- E22

- E23

- E24

- E25

- E26

- E27

- E28

- E29

- E30

- E31

- E32

- E33

- EX2

-

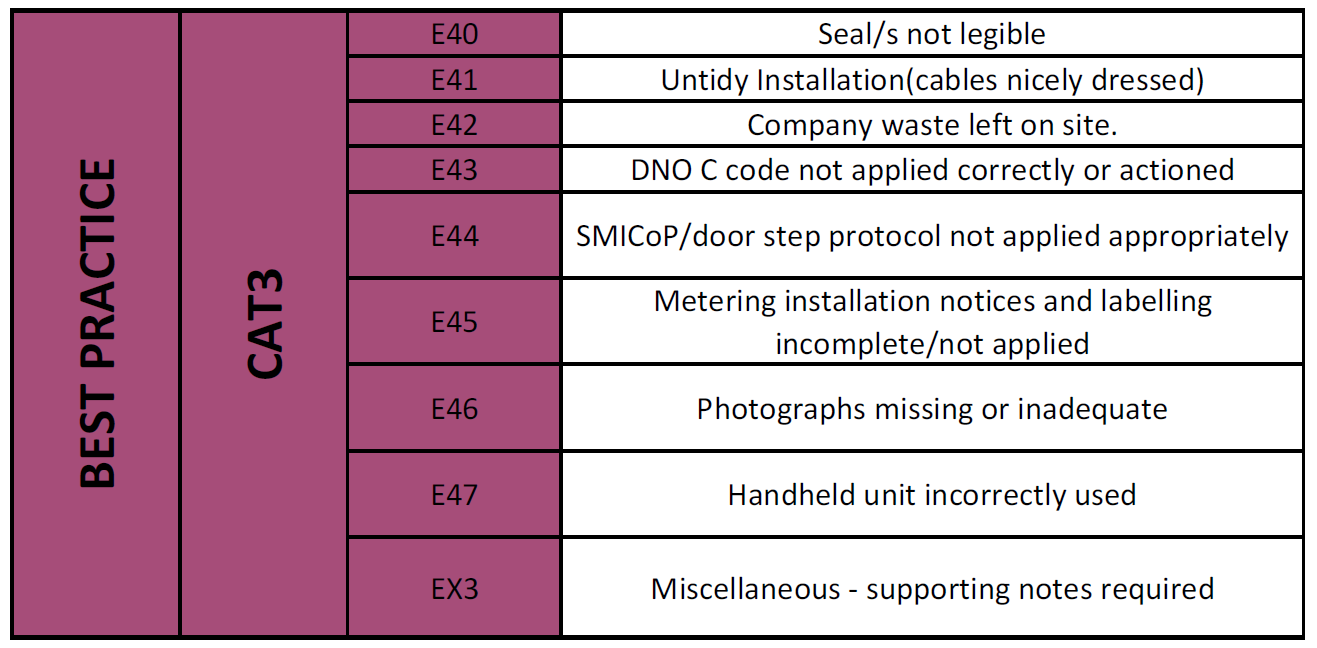

CAT3 issue/s identified

-

-

Select all that apply (include any selected earlier)

- E40

- E41

- E42

- E43

- E44

- E45

- E46

- E47

- EX3

-

Please provide details of all audit non-conformances

-

Have you provided any coaching during the site visit?

-

Please provide details of the coaching provided

-

Please provide any good feedback observed during the site visit

-

Signed by Engineer

-

Signed by Auditor