Information

-

Select your project

-

Planned HSE Inspection - Fixed Pedestal Drills

-

Conducted on

-

Inspection conducted by:

Fixed Pedestal Drills

-

The hazard inspection must be conducted by a Supervisor and/or Safety and Health Representative and/or an employee, as follows:

1. For EVERY inspection requirement, indicate the item as Compliant (C), Non-Compliant (NC) or Not Applicable (N/A)

2. For every non-compliance identified, provide the location and a description in the comments section. Note: Include positive comments on compliance, not just negatives

3. Enter defects or non-conformances in the applicable site registers

4. At inspection completion, discuss the non-conformances with the Area Superintendent and determine an action, completion date and responsible person – enter this in the agreed actions section of this form

5. Forward the completed inspection to the Safety Department

6. The Safety Department is to check that ALL identified non-conformances for that month have been corrected and or entered into INX.

Pedestal Drill

-

Enter the Pedestal Drill ID number

-

Take a photo of the Pedestal Drill

-

Is the OEM manual supplied?<br>- in English?<br>- includes work instructions?<br>- identifies hazards?

-

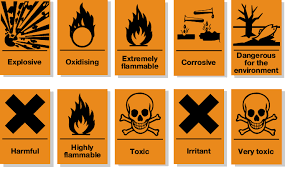

Is the appropriate PPE signage located above the pedestal drill?

-

Is appropriate personal protective equipment available?<br>- single eye protection (for drills)<br>- hearing protection - ear plugs or ear muffs

-

Are the vice jaws in good condition and can the jaw be freely moved along the slides (wind open to the maximum position, then wind closed to the minimum position)?

-

Are suitable locking mechanisms in place where the vice can be secured to the drill bed?

-

Is the drill chuck in good operational condition and free from rust or corrosion?

-

Is the drill chuck in good condition? (ask frequent users if drill bits are constantly slipping whilst drilling, drill chuck teeth may be worn)

-

Is the drill chuck guard adequately secured to the drill and functioning to prevent entanglement?

-

Is a speed guide chart located on the drill? (ask frequent users if current speed settings are suitable for general use)

-

Are all operating switches, buttons and control handles in good working condition?(including foot lock out switches)

-

Has the swarf been cleaned up after the previous use?

-

Are electrical cords in good condition and correct test tag in place?

-

Is the area kept tidy and housekeeping practices maintained?

-

Is personal protective equipment signage displayed?

-

Is an effective emergency stop button fitted?

Sign Off

-

Person conducting inspection: