Information

-

Select your Project

-

Planned HSE Inspection - Hazardous Chemical Inspection

-

Conducted on

-

Inspection conducted by:

Hazardous Chemical Inspection

-

The hazard inspection must be conducted by a Supervisor and/or Safety and Health Representative and/or an employee, as follows:

1. For EVERY inspection requirement, indicate the item as Compliant (C), Non-Compliant (NC) or Not Applicable (N/A)

2. For every non-compliance identified, provide the location and a description in the comments section. Note: Include positive comments on section. Note: Include positive comments on compliance, not just negatives

3. Enter defects or non-compliances in the applicable site registers, i.e. electrical equipment defects must be entered into the Electrical Register

4. At inspection completion, discuss the non-conformances with the Area Superintendent and determine an action, completion date and responsible person - enter this in the agreed actions section of this form

5. Forward the completed inspection to the Safety Department

6. The Safety Department is to check that ALL identified non-conformances for that month have been corrected and or entered into INX.

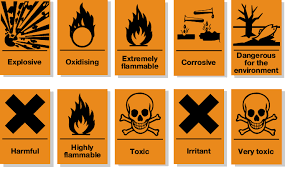

MSDS and ChemAlert (* Randomly inspect four (4) MSDS sheets for the purpose of these inspection points)

-

MSDS and Chemalert Cabinet / Storage Location

MSDS Folders / Chemalert

-

Enter MSDS Folders / Chemalert Location

-

Take photo of MSDS folder at storage location / MSDS sheet auditing

-

Is the location of MSDS files clearly marked and accessible?

-

Is there a nominated person to keep the MSDS file current?

-

Does the MSDS file provide information on the health hazards associated with the use and handling of substances?

-

Does the MSDS file provide information on the environmental hazards associated with the use, storage, handling and disposal of substances?

-

Does the MSDS file describe the identity, chemical and physical properties of substances?

-

Is an MSDS available for each hazardous substance used or produced in the workplace? (Randomly check)

-

Have personnel been audited, at random, for knowledge of location, purpose and use of MSDS?

-

Does ChemAlert report any breaches in allowable limits for any Hazardous Substances on site?

Gas Cylinders

-

Gas Cylinder Storage Location / Area

Gas Storage Location

-

Enter Location of Gas Storage Area

-

Are oxy/acetylene cylinders in use properly secured?

-

Are pressure reducing regulators and flash back arrestors fitted on all cylinders and hand pieces prior to use?

-

Are all oxy/acetylene hoses in use in good order (not perished)?

-

Are reserve cylinders of oxy/acetylene stored separately and secured upright, 3 metres apart (unless separated by a fire separation wall)?

-

Are all oxy/acetylene cylinders on trolleys chained and secured?

Storage Areas

-

Hazardous Chemical Storage Areas

Storage Areas

-

Location of Storage Area

-

Take Photo of Storage Area

-

Is refrigerant gas information recorded?

-

Are correct hazchem signs ("Acetylene", "Flammable Gas", "Oxygen", “Oxidising Gas") in place?

-

Are chemicals and flammable liquids stored in a safe area or in a safety cabinet and correctly sign posted?

-

Is there any evidence of spills/stains outside the storage area?

-

Do the storage areas have adequate ventilation?

-

Are PPE requirements signposted?

-

Has appropriate temperature control been implemented if required?

-

Are containers holding liquids clearly labelled?

-

Incompatible substances are not stored together?

-

Are containers holding liquids of an appropriate type and in good condition?

-

Is all waste being disposed of as per MSDS/Controlled Waste requirements?

-

Are appropriate fire extinguishers in place, charged, in date and accessible?

-

Are alarm systems in the storage areas serviced on a regular basis?

-

Does the site Emergency Response Plan cover emergencies involving hazardous substances?

Sign Off

-

Person conducting inspection: