Title Page

-

Conducted on

-

Prepared by

-

Site conducted

-

Section

-

Shift

-

Document Number

Planned Inspection

Underground Work Area Standards

-

No rubbish (gloves/earplugs/food containers/resin boxes/ground support leftovers/minsup clips etc) laying anywhere in any drive or on decline.

-

Ensure signage is clean and properly hung against walls when not in use (clean side facing wall so doesn’t get muddy when vehicles drive past)and hanging points are clearly marked with red/white paint

-

Grade lines painted right to the face and re-painted if needed

-

Water/air hoses have minsup clips and no splits at all in the hoses (especially water)

-

Unused hoses rolled neatly and hung off triple hooks/L pins (secure with rope/old bellwire to keep rolled up)

-

Headings properly watered down from the end of vent bags (including walls)

-

Windrows kept below gumboot height (especially from face back to 20m where jumbo op/nipper will be walking beside drills and obvious rock trip hazards bogged off main travelway

-

All cables/hoses off the ground right to the back of the drills (there should be a triple hook basically beside the back of the drill (ie they should be at regular intervals) so that there is no reason for cables/hoses to be laying for 20m on the ground

-

No tears/holes in Vent bags except in SHOT bag

-

Clearly paint up level names/sign hanging points/end of firing lines/droppers and services

-

Bellwire/nonel cords etc rolled up and disposed of, not left laying along drives

-

Underground stores areas (vent/ground support) properly set up so IT can unload etc neatly. Ensure blue metal signs in place to clearly label what goes where, and ensure there is a rubbish bin available that can be picked up by IT

-

Sumps to be bogged regularly and set up so that pumps can be safely and efficiently lifted.

-

Minimal water pooling in drive (and none above gum boot height), get bogger to fill in holes, or jumbo ops to pop toes. Ensure ore drives are inclined for drainage.

-

No bent bolts/mesh sticking outside on pillars/walls. Get them cut off.

Service and Ventilation Standards

-

-

Signage in place – as per ‘Underground Standards’

-

Firing line and communication ribbon extended as required

-

No services or obstruction running through load bays.

-

Dewater lines ran out into adjacent sump.

-

All hoses and cables run along walls and clear of floor

-

Vent bag run level at highest point in drive, within 30m of face and shot bag at the end

-

Vent not ran through middle of load bay

-

Vent rips repaired or bag replaced

-

Droppers anchored 1 metre apart and marked up at grade line with Triple hooks in position

-

Services hung level and tight along shoulder line within 30m of face

Development Bogging Standards

-

-

Is there any development bogging activities in the work area?

-

Re-entry and gas testing have been completed

-

Heading watered down adequately

-

Hoses removed from heading and stored at droppers

-

Development material type is confirmed (ore/waste)

-

Bog heading as per site SWI

-

Last two cuts boned out to check for lifter misfires

-

Supervisor notified of any misfires

-

Windrows to be removed and roadworks completed

-

Face to be raked using bucket

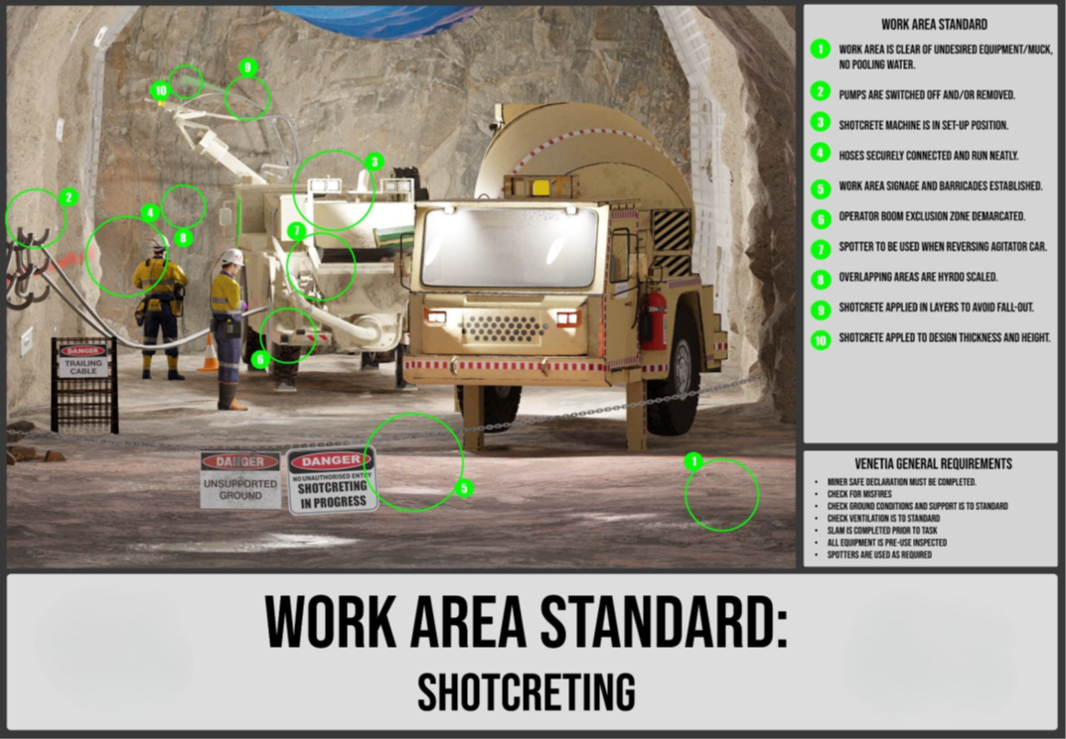

Shotcrete Standards

-

-

Is there any Shotcrete activities in the area?

-

Water/air hoses run – as per ‘Underground Standards’

-

Protruding mesh or other hazard have been removed

-

Pumps or other items removed from heading to avoid damage through overspray

-

Heading hydroscaled overlapping previous cut

-

Fibrecrete applied in layers to avoid fall out

-

Fibrecrete applied to design thickness and height

-

Re-entry time logged with mine control / placed on sign

-

Overspray washed from infrastructure (vent doors etc)

Jumbo Support Standards

-

-

Is there any Jumbo support activities in the area?

-

J/box and eye bolt – as per ‘Underground Standards’

-

Trailing cable hung – as per ‘Underground Standards’

-

Water hoses hung – as per ‘Underground Standards’

-

Pump to be installed to remove standing water

-

Ground support consumables organised against wall

-

Ground support installed as per geotech instruction

-

Bolt and ring spacings as per site requirements

-

Pull rings installed on splitsets as per site requirements

-

Mesh not stacked with more than two sheets together

-

Face has been mechanically scaled

-

Lasers are functional on Jumbo and in use

-

Mesh is brought to correct height from floor as per the relevant ground support standard

-

Shotcrete probe holes have been installed

-

Site controls around drilling into un-prepped face have been complied with Nipper in cab

-

Loader is arranged to clean up face on completion

-

Supervisor notified of any misfires and misfire log filled in

Jumbo Drilling Standards

-

-

Is there any Jumbo Drilling activities in the area?

-

J/box and eye bolt – as per ‘Underground Standards’

-

Trailing cable hung – as per ‘Underground Standards’

-

Water hoses hung – as per ‘Underground Standards’

-

Chainage verified and recorded on face for every cut

-

Grade lines painted back to previous markings

-

Face to be marked up in full

-

Floor to be marked with perimeter and centre line as a minimum using rocks or similar

-

Pump to be installed for down grade cuts

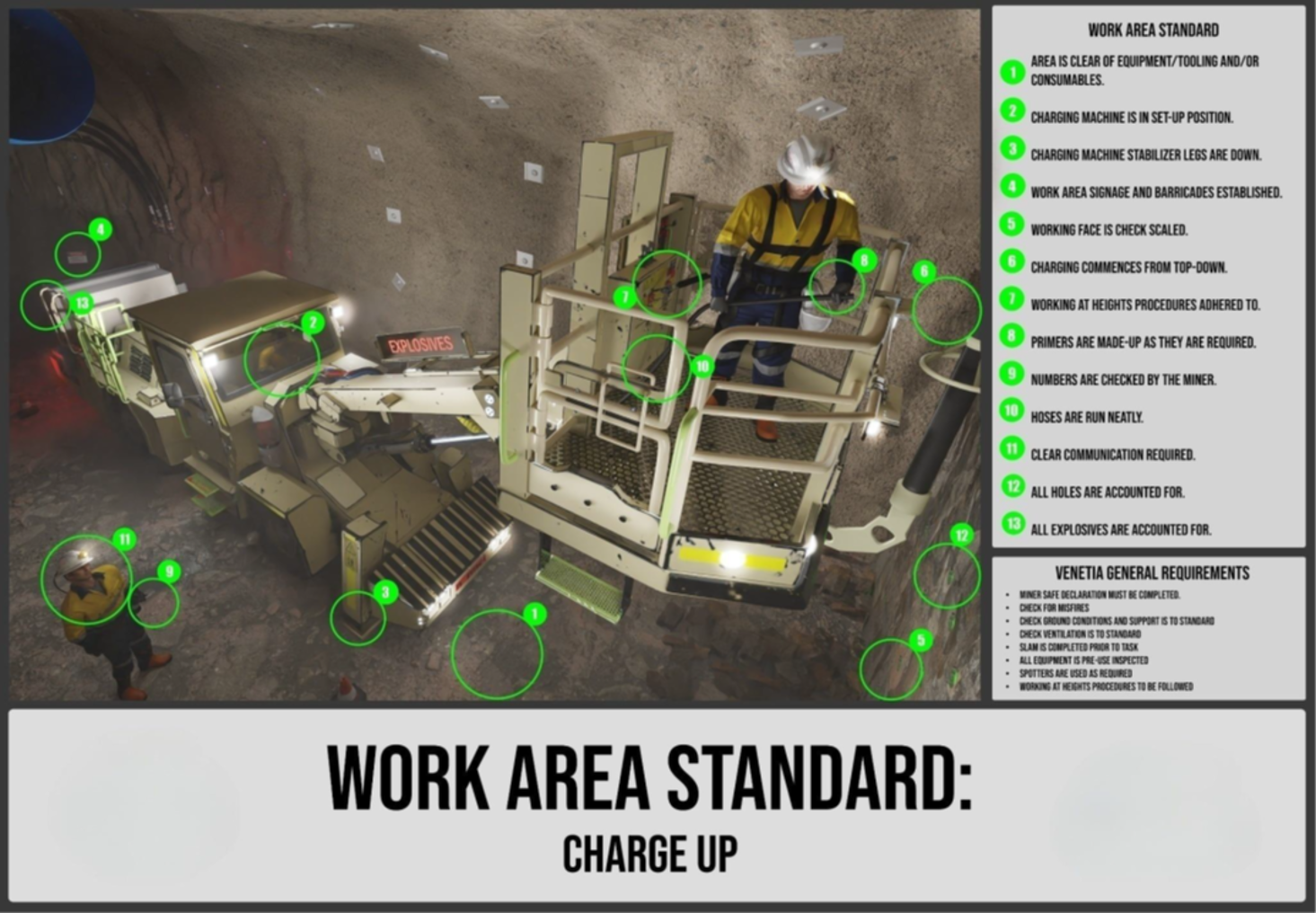

Development Charge Up Standards

-

-

Is there any Development Chare Up activities in the area?

-

Heading clean and free of mining consumables

-

Heading clear of infrastructure that could be damaged

-

If a turnout is being charged, confirm cablebolts are installed at intersection

-

Area has been hand scaled

-

Charging carried out as per relevant site SWI

-

Firing line marked – as per ‘Underground Standards’

Cable Bolting Standards

-

-

Is there any Cable bolt activities in the area?

-

J/box and eye bolt – as per ‘Underground Standards’

-

Trailing cable hung – as per ‘Underground Standards’

-

Water hoses hung – as per ‘Underground Standards’

-

Pump to be installed where required

-

Cement neatly stacked to minimise manual handling

-

Water metre, clino, rod counter all functional

-

Cablebolts installed as per plan and as per SWI

-

Cables grouted to collar

-

Cement bags, pallets and cable offcuts removed

Production Drilling Standards

-

Is there any Production Drilling activities in the area?

-

J/box and eye bolt – as per ‘Underground Standards’

-

Trailing cable hung – as per ‘Underground Standards’

-

Water/air hoses run – as per ‘Underground Standards’

-

Pump to be installed where required

-

Floor to be cleaned prior to drilling

-

Collarpipe and consumables to be stored against wall

-

Walls marked with ring spacings as per plan

-

Centreline marked in backs

Production Charge Up Standards

-

-

Is there any Production Charge Up activities in the area?

-

Area clean and free of mining consumables

-

Area clear of infrastructure that could be damaged

-

Area has been hand scaled if required

-

Working at heights equipment tagged and certified

-

Charging carried out as per relevant site SWI

-

Firing line marked – as per ‘Underground Standards’

Production Bogging Standards

-

-

Is there any Production Bogging activities in the area?

-

Stope clearance and gas testing have been completed

-

Draw point sprays in use as required

-

Travel ways clear of spillage

-

Cab Lines painted up and adhered to

-

Bog draw point as per site SWI

-

Bunds in place when draw point is not active

-

Windrows to be removed and roadworks completed

General

-

Additional Comments

Review

-

I HEREBY CERTIFY THAT ALL THE ABOVE ITEMS WERE CHECKED AND DECLARE THE WORKING AREA/PLACE SAFE FOR ALL WORKERS.

-

Name & Signature of person conducting Inspection: