Information

-

Document No.

-

Risk Assessment number

-

Conducted on

-

Prepared by

-

Location

-

Personnel

Part A- Assessment Summary

Assessment Summary

-

Assessment Title (Plant Description)

-

Plant ID No.

-

Licence/Registration number

-

Has plant been entered into asset register?

-

Make

-

Model

-

Serial Number

-

Site:

-

Concept

-

New/initial/commissioning

-

Alteration

-

Re-location

-

Revised assessment

-

Department:

-

Construction

-

Town Maintenance

-

Location:

-

Loxton

-

Waikerie

-

Plant/Project No:

-

Date of purchase

-

Used for

-

Used by

-

Incident history (incident numbers):

Risk Assessment Team

-

1. Name

-

Position

-

Waikerie Works Manager

-

Loxton Works Manager

-

Loxton Town Maintenance Team Coordinator

-

Loxton Construction Team Coordinator

-

Waikerie Works Manager

-

Waikerie Town Maintenance Team Coordinator

-

Signature

-

Date

-

2. Name

-

Position

-

Loxton Works Manager

-

Loxton Town Maintenance Team Coordinator

-

Loxton Construction Team Coordinator

-

Waikerie Works Manager

-

Waikerie Town Maintenance Team Coordinator

-

Signature

-

Date

-

3. Name

-

Position

-

Loxton Works Manager

-

Loxton Town Maintenance Team Coordinator

-

Loxton Construction Team Coordinator

-

Waikerie Works Manager

-

Waikerie Town Maintenance Team Coordinator

-

Signature

-

Date

-

4. Name

-

Position

-

Loxton Works Manager

-

Loxton Town Maintenance Team Coordinator

-

Loxton Construction Team Coordinator

-

Waikerie Works Manager

-

Waikerie Town Maintenance Team Coordinator

-

Signature

-

Date

Part B- Sign Off

Department Manager/Supervisor

-

Name

-

Signature

-

Date

OHS Rep, Team Leader or Operator

-

Name

-

Signature

-

Date

OHS/Risk Coordinator

-

Name

-

Signature

-

Date

Part C- Operator Training

Training

-

Is a Licence or Training needed to operate this plant?

-

Details:

-

Is a Trade Certificate needed to operate this plant?

-

Details:

-

Is there a SOP associated with this plant?

-

Details:

-

Is there an Induction procedure associated with this plant?

-

Details:

-

List of related Standards, ACOP's, SOP's, Operating manuals, Documents.

Part D- Hazards & Controls

Hazards, Controls & Improvements

-

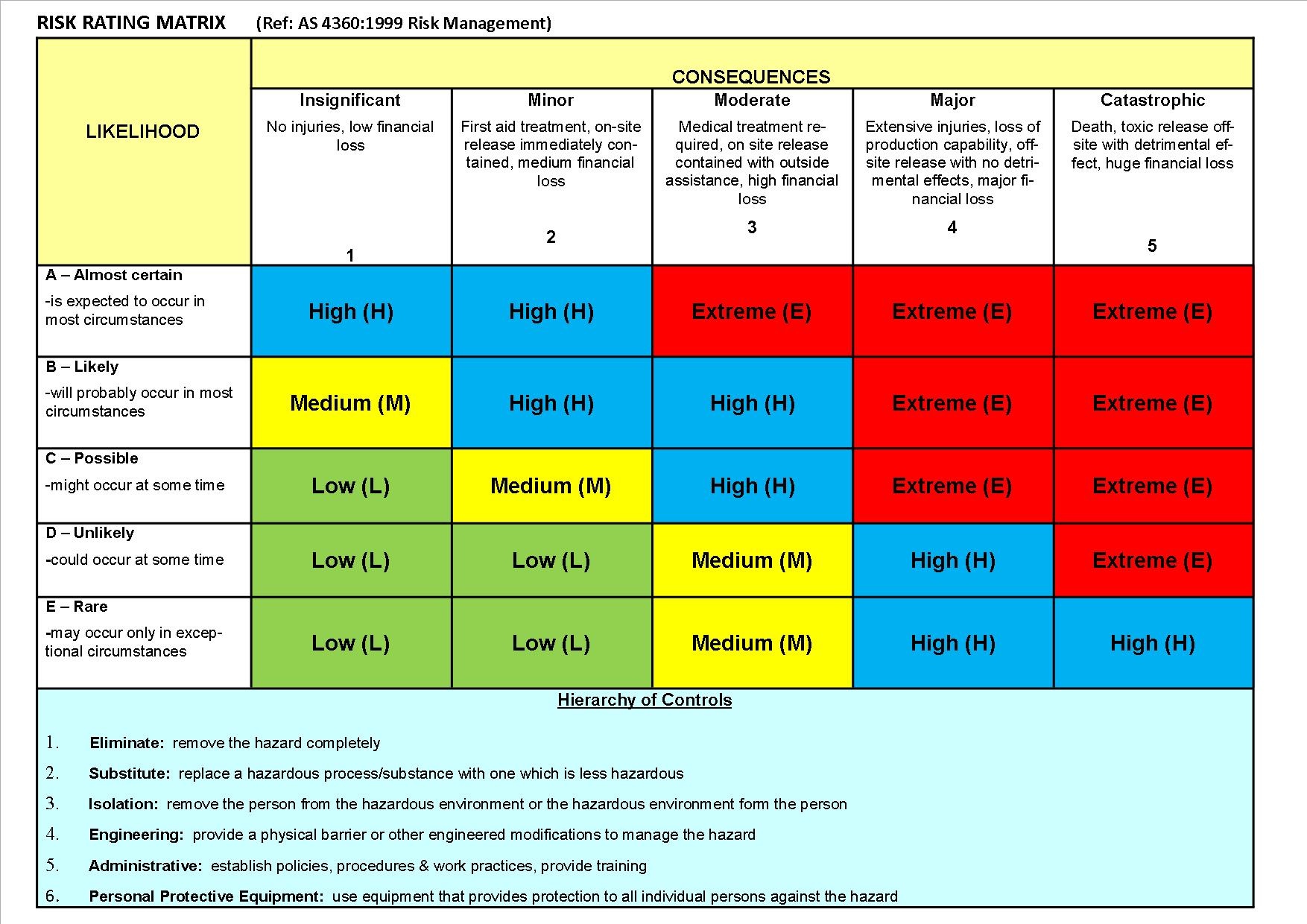

Risk Matrix

A. Entanglement- Due to...

-

A1 Can anyone's hair, clothing, gloves, jewellery, cleaning materials become entangled in moving or spinning parts?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

A2 Can someone/something become crushed between objects?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

A3 Can someone/something get Cuts, Stabbed, Abrasions or Puncture wounds from using this plant?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

A4 Can someone/something become amputated from using this plant?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

A5 Can someone/something become injured due to friction while using this plant?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

A6 Other (specify)?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

B. Crushing- Due to...

-

B1 Material falling off the plant

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

B2 Uncontrolled or unexpected movement of the plant?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

B3 Lack of capacity of the plant to be slowed, stopped or imobilised?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

B4 The plant tipping or rolling over?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

B5 Parts of the plant collapsing?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

B6 Coming into contact with moving parts during testing, inspection, operation, maintenance, cleaning or repair?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemen

-

Is this an acceptable level of risk?

-

Why?

-

B7 Being thrown off or under the plant?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

B8 Other (Specify)?

-

Details:

-

Existing control measures in place?

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

C. Cutting, Stabbing & Puncturing- Due to...

-

C1 Coming into contact with sharp or flying objects?

-

Details:

-

Existing control measures in place?

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

C2 Coming into contact with moving parts of plant during testing, inspection, maintenance, cleaning or repair of the plant?

-

Details:

-

Existing control measures in place?

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

C3 The plant or work pieces disintegrating?

-

Details:

-

Existing control measures in place?

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

C4 Work pieces or plant pieces being ejected?

-

Details:

-

Existing control measures in place?

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

C5 The mobility of the plant?

-

Details:

-

Existing control measures in place?

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

C6 Uncontrolled or unexpected start-up or movement of the plant?

-

Details:

-

Existing control measures in place?

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

C7 Other (specify)?

-

Details:

-

Existing control measures in place?

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

D. Shearing- Due to..

-

D1 Body parts being sheared between two parts of the plant or parts of the plant and a work piece or structure?

-

Details:

-

Existing control measures in place?

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

E. Friction Burn- Due to...

-

E1 Contact with friction heated moving parts/surfaces of plant or materials?

-

Details:

-

Existing control measures in place?

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

F. Striking by Moving Objects- Due to...

-

F1 Uncontrolled or unexpected movement of the plant or materials?

-

Details:

-

Existing control measures in place?

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

F2 The plant, parts or works pieces disintegrating?

-

Details:

-

Existing control measures in place?

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

F3 Work pieces being ejected?

-

Details:

-

Existing control measures in place?

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

F4 Mobility or movement of the plant or plant parts?

-

Details:

-

Existing control measures in place?

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

F5 Other (specify)?

-

Details:

-

Existing control measures in place?

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

G. High Pressure Fluid Injury- Due to...

-

G1 Coming into contact with fluids under high pressure due to plant or hose failure or misuse of the plant?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

H. Suffocation- Due to...

-

H1 Lack of oxygen or atmospheric contamination?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

I. High Temperature Injury- Due to...

-

I1 Coming into contact with objects at high temperatures?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

I2 Fire?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

J. Thermal Discomfort- Due to...

-

J1 Exposure to high or low temperatures?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

K. Electrical Shock or Electrical Burn- Due to...

-

K1 The plant contacting live electrical conductors?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

K2 The plant working in close proximity to electrical conductors?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

K3 Overload of electrical circuits?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

K4 Damaged or worn electrical cables, leads or switches?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

K5 Water near electrical equipment?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

K6 Inadequate isolation of electrical power supply?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

K7 Residual electrical energy?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

L. Explosion- Due to...

-

L1 Explosion of flammable or explosive gases, vapours, liquids, dust or other substances triggered by operation of the plant or material?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

L2 High pressure build up?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

M. Slipping, Tripping or Falling- Due to...

-

M1 Uneven or slippery surfaces?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

M2 Poor housekeeping, e.g. equipment, etc. not stored properly?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

M3 Obstacles being placed in the vicinity of the plant?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

M4 Other (specify)?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

N. Falling from Height- Due to...

-

N1 Lack of a proper work platform?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

N2 Lack of proper stairs or ladder?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

N3 Lack of guardrails or suitable edge protection?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

N4 Unprotected holes, penetrations or gaps?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

N5 Poor floor or walking surfaces, not slip resistant?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

N6 Steep or sloping walking surfaces?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

N7 Collapse of the supporting structure?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

N8 Other (specify)?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

O. Ergonomics or Plant Environment Injury- Due to...

-

O1 Poorly designed seating?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

O2 Repetitive body movements?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

O3 Constrained body posture or the need for excessive effort?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

O4 Design deficiency causing mental or psychological stress?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

O5 Inadequate or poorly placed lighting?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

O6 Lack of consideration given to human error or human behaviour?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

O7 Mismatch of the plant with human traits and natural limitations?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

O8 Other (specify)?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

P. Other Hazards- Injuries or ill health due to...

-

P1 Chemicals?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

P2 Dust?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

P3 Radiation?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

P4 Toxic gases?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

P5 Noise?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

- Low

- Medium

- High

- Extreme

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

P6 Fumes?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

-

P7 Vibration?

-

Details:

-

Existing control measures in place:

-

Risk rating before controls

-

Improvements needed to ensure safety:

-

Risk Score after controls implemented:

-

Is this an acceptable level of risk?

-

Why?

Part E- Action Plan

Recommended Improvements

-

Description of improvement, person responsible, timeframe, date of completion & signed off.

- Improvement

-

Description of improvement:

-

Person responsible:

-

Date to be completed by:

-

Actual date of completion:

-

Name of person completing improvement:

Part F- Media

Photos/drawings of Plant

-

Photos of plant:

- Photo

-

Description of photo:

-

Drawing(s) of plant:

- Drawing

-

Description of drawing