Title Page

-

Contract Number

-

Project

-

Conducted on

-

Conducted by

-

Location

-

Personnel

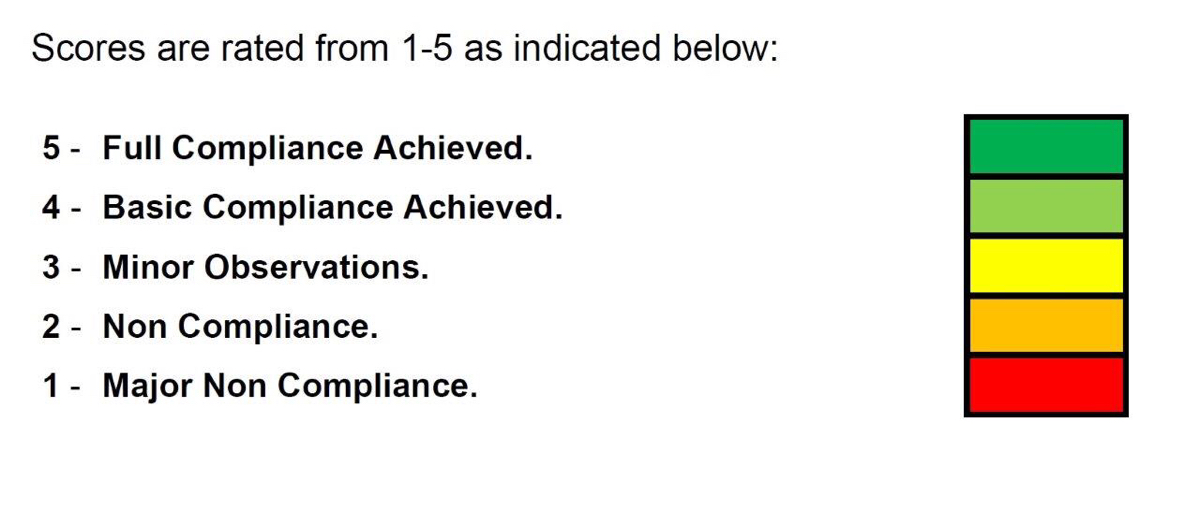

PMC AUDIT SCORING SYSTEM

FIRE & EMERGENCY

-

Has a fire emergency evacuation plan been established for the project

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Has a fire risk assessment been concluded for both the project and the offices

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Are there suitable numbers of trained fire personnel

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Are there suitable numbers of fire extinguishers available on the project

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Is hot works controlled under a suitable permit to work system

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Are flammable materials contained away from ignition sources

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Has a no smoking policy been established for the project, are designated smoking areas identified

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Is there a suitable means for raising the alarm on the project

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Are evacuation drills undertaken frequently and recorded

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Are arrangements in place to test and inspect all fire fighting equipment on the project

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

FIRST AID ARRANGEMENTS

-

Are their sufficient numbers of first aid personnel on the project

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Are first aiders easily identifiable both in the office and on the project

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Is there a fully stocked first aid kit readily available and accessible

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Is their a procedure for recording accidents and incidents on the project

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Are near miss reports discussed and investigated giving recommendations for prevention

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Are medical records available for employees engaged in high risk working activities

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Are emergency vehicle access routes kept clear from obstruction

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

PLANT & EQUIPMENT

-

Are all operators of plant and equipment suitably qualified and deemed competent to perform the tasks

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Is all plant & equipment on the project maintained in accordance with the manufacturers instruction

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Does all plant on site come with a valid certification of conformity (examination test)

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Does the plant operator undertake frequent checks and recorded inspections of his plant / equipment

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Does all plant on the project have the necessary safety features to warn, or prevent collision

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Does all heavy plant on the project have operational beacons while in use

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Does a log book record the hours of the appointed operators

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Is there a suitable demarcation zone around any plant that encroaches onto other persons

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

WORK AT HEIGHT

-

Is adequate edge protection provided for all work at heights that includes 470mm & 950mm handrails

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Do employees have a working platform that provides 600mm of clearance

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Does the scaffold have toe boards fitted to prevent the falls of material

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Is there a procedure for inspecting scaffolds prior to handover and every 7 days therein

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Are scaffolders on the project competent with recognised valid training certificates/ cards

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Do ladders reach 1.2mtr (4 rungs) above the landing levels

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Are ladders free from any obstruction and in good repair

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Are ladders secured to prevent free movement and positioned at the correct angle 75°

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Is all work at height covered under an 'approved' method statement and risk assessment

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Do scaffolds display a current tagging system that explains the scaffold status

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

EXCAVATIONS

-

Is there a 'permit to work' procedure established for excavation works

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Is there suitable edge protection in place around the excavation to prevent falls of both plant and workers

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Has access and egress been considered while working in the excavation

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Have the sides been protected from the risk of collapse i.e. drag boxes, trench supports etc.

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Are spoil heaps well away from the excavation edge

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Is plant and machinery positioned 1.5mtr from the excavation edge

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Are signs erected warning of deep excavations

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Are excavations inspected and recorded every 7 days, including after inclement weather

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

WELFARE FACILITES

-

Are toilets fit for purpose, in good order, and cleaned on a regular basis

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Do all welfare facilities have hot and cold running water for washing and oblation purposes

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Are sanitary and cleansing provisions provided within the facilities

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Are there provisions provided for the storage and preparation of food

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Is lighting and ventilation acceptable in the provided welfare

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Is there a schedule for maintenance and cleaning of the welfare facilities

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Are there sufficient numbers of seating and resting areas provided for employees on the project

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Is drinking water provided around the project and maintained with filtration changes every >30 days

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Do rest areas provide sufficient comfort from extreme heat and direct sunlight

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

TEMPORARY WORKS

-

Does all formwork come with a system design for erection and dismantling

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Has the contractor appointed a temporary works coordinator

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Have all temporary works been approved prior commencement

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Is there a permit to load / strike established

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

TRAFFIC MANAGEMENT

-

Is there an approved traffic management and logistics plan on the project

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Are access arrangements established on the project that don’t interact with moving plant /equipment

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Are speed limitation and traffic warning signs displayed throughout the project

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Is security established on the project to prevent unwanted/ unauthorised entry

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Is there displayed information for delivery vehicles and visitors to the project

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

ELECTRICAL

-

Are all electrical installations protected by RCD - ELCB

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Are all extension cables free from visual damage and splicing

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Are all cables managed to prevent unnecessary tripping hazards

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Are all socket outlets weather proof to prevent against water ingress

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Have all temporary and permanent installations been carried out by a competent electrical engineer

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Are all exposed balustrades and secondary steel components earth to prevent electrical shock

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Is task lighting provided and acceptable for the locations

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Is suitable signage displayed on the project warning of electrical shock risks

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

-

Are mains distribution units (MDU) stationary fixed, and secured with a padlock

- Full Compliance Achieved

- Basic Compliance Achieved

- Minor Observations

- Non Compliance

- Major Non Compliance

- Not Applicable

-

Note

-

Media

Additional comments

-

Additional comments

-

ENVIRONMENTAL

End

-

Auditor Signature

-

Representative signature

-

Project Manager signature