Title Page

-

Document No.

-

Rack Check Found Issue Report

-

GMX 512/A1AC

-

Conducted on

-

Team Lead or Supervisor initials

-

This report is to record a discussion between production supervisor or team lean and a production operator regarding an issue found in a finished good rack check.

-

Top Number

-

Rack number

-

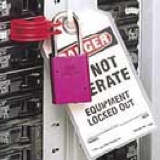

Take a photo of the issue if possible

-

Issue(s) found in rack check.

-

Operator Name

-

Station Where Issue Occured

-

Is this a quality or engineering issue?

-

FYI this is not an official step in the write up/disciplinary process. This is only a recording document. You may be asked to inspect for defects/issues outside of normal work instructions. Please see Follow up Actions to continue.

-

Was the above issue due to an operator mistake?

-

Is this a repeat mistake?

-

FYI this is not an official step in the write up/disciplinary process. This is only a recording document. This document can be used if/when disciplinary process begins as an example of poor quality. Failure to follow corrective actions may result in the starting of the discipline process up to termination.

-

FYI this is not an official step in the write up/disciplinary process. This is only a recording document. This document can be used if/when disciplinary process begins as an example of poor quality. Failure to follow corrective actions may result in the starting of the discipline process

-

Corrective Follow Up Action(s):

-

Does the operator understand the above stated issue(s) and the above stated corrective action(s)

-

Explain again to the operator the issues and corrective issue until fully understood. When operator understands change answer to yes.

-

TEAM LEAD/ PRODUCTION SUPERVISOR: By signing here you certify that the issue(s) and corrective action(s) have been explained and are understood by the operator.

-

OPERATOR: By signing here you acknowledge that you understand the above issue(s) and you will follow the stated corrective actions.