Information

-

Audit Title

-

Document No.

-

Client / Site

-

Conducted on

-

Prepared by

-

Location

-

Personnel

1. Working at Heights

-

1.1. Is there a fall risk of 2m or more? (Inc Voids, Pits & Trenches)

-

1.2. Is there a lack of edge protection?

-

1.3. Is there unsafe or incomplete edge protection?

2. Plant and Equipment

-

2.1. Is there Unsafe or damaged plant/equipment? (including missing or damaged guards)

-

2.2. Is there Incorrect plant /equipment for job? (e.g. grinding discs for cutting)

-

2.3. Is there unsafe or incompatible attachments used with plant/equipment?

-

2.4. Are there any unlicensed operators?

-

2.5. Are there sufficient safe work instructions?

-

2.6. Has there been sufficient training in safe operation, clean-up and maintenance?

-

2.7. Has there been sufficient training of LOTO (lock out, tag out) procedures for cleaning, servicing and maintenance?

-

2.8. Is there a lack of inspection regime?

-

2.9. Are vehicle stands marked with SWL?

-

2.10. Is the forklift serviced regularly?

-

2.11. Are daily checks conducted on the forklift?

-

2.12. Have all attachments to the forklift been approved by an engineer and does the compliance plate on the forklift reflect these attachments?

-

2.13. Are warning lights and reversing beepers operating?

-

2.14. Does the operator hold appropriate certificate / licence?

-

2.15. Are manufacturers and designers operating instructions available for all plant?

-

2.16. Are hand tools in good condition?

-

2.17. Are handles and shafts free from splits, deep cuts and damage?

-

2.18. Are hand tool heads checked regularly to ensure they are secured?

-

2.19. Are portable power tools in good condition?

-

2.20. Are adequate storage facilities provided?

-

2.21. Do staff use power tools correctly with RCD's?

-

2.22. Are all guards in place?

-

2.23. Do staff correctly use pressure equipment?

-

2.24 Is compressed air equipment maintained on a regular basis, and is this maintenance recorded?

-

2.25. Are gas cylinders correctly stored - secured by chain or bar?

-

2.26. Are welding screens or curtains in place when welding?

-

2.27. Are all gas cylinders turned off and hoses rewound when not in use?

-

2.28. Are welding hoses and leads in good condition?

-

2.29. Are flashback arrestors in place?

-

2.30. Is PPE available and used for welding?

-

2.31. Is a fire extinguisher located in the area?

-

2.32 Is the workbench / area tidy?

-

2.33. Is the required signage and safety instructions displayed?

-

2.34. Is an eyewash station available?

-

Add media

3. Scaffolds

-

3.1. Are any unlicensed persons erecting scaffold above 4m?

-

3.2. Is there any unsafe or incomplete scaffold?

-

3.3. Is there sufficient inspection protocol for scaffold?

-

3.4. Is there Incompatible scaffold components? Unlabelled or do not meet AS?

-

3.5. Has Safe Work Load (SWL) been exceeded? (tools, stored materials, number of persons)

4. Lifting Equipment

-

4.1. Is there any loads lifted over persons, close proximity to obstacles incl. overhead power lines?

-

4.2. Is there a lack of maintenance, testing and inspection?

-

4.3. Is there sufficient SWL information displayed?

-

4.4. Is there a daily inspection protocol?

-

4.5. Is there unsafe or damaged lifting equipment, including ropes, slings, chains, hooks?

-

4.6. Is there any lifting equipment unlabelled, does not meet AS, no SWL displayed?

-

4.7. Are there any unlicensed operators?

-

4.8. Is there any SWL of plant or any lifting equipment exceeded?

-

4.9. Is all lifting gear tagged, current, stored, appropriately and in good condition?

-

4.10. Is the SWL displayed on relevant lifting equipment (including lifting beams)

-

4.11. Is the correct lifting equipment being used for lifting activities?

5. Harness and Equipment

-

5.1. Is there any unsafe or damaged harness or equipment?

-

5.2. Is there any incompatible hooks/equipment?

-

5.3. Is there any unlabelled or does not meet Australian Standards Harnesses or Equipment?

-

5.4. Is there any unsafe or uncertified anchor points?

-

5.5. Is there a inspection protocol for equipment?

-

5.6. Has there been formal training for operators?

6. Ladders

-

6.1. Are ladders in good condition?<br>(No domestic ladders on site)

-

6.2. Is there unsafe positioning of ladders?

-

6.3. Are there any unsecured ladders?

-

6.4. Are there any ladders unsuitable for job? (e.g. metal ladder used for electrical work)

7. Hazardous Manual Tasks

-

7.1. Is there a identification hazardous manual tasks?<br>

-

7.2. Is there a assessment of hazardous manual tasks?

-

7.3. Is there any risk controls? (examples: no job rotation, lighter loads, trolleys, lifting equipment, etc)

-

7.4. Has sufficient training been given for risk controls and safe lifting/ team lifting techniques?

8. Hazardous Chemical (including fuel and oil)

-

8.1. Is there any unsafe storage locations? (e.g. flammables near ignition sources, spills could enter storm water drains, etc)

-

8.2. Is there any incompatible chemicals stored near each other?

-

8.3. Is there any spill containment equipment?

-

8.4. Are there Safety Data Sheets available on site?

-

8.5. Is there a emergency procedure for injury/spills/fire etc?

-

8.6. Is there any excessive quantities stored on site or in vehicles?

-

8.7. Is there sufficient ventilation?

-

8.8. Is there any Insufficient, or incorrect, PPE?

-

8.9. Is there any unsuitable storage containers? (unlabeled or stored in food containers)

-

8.10. Have all chemicals been identified?

-

8.11. Are all chemicals correctly stored?

-

8.13. Are containers we'll marked/labelled correctly?

-

8.14. Is there appropriate ventilation for both use and storage?

-

8.15. Are Material Safety Data Sheets (MSDS) provided and available to all staff?

-

8.16. Is there a MSDS register available on site? (Check if several hazardous substances found in the workplace are in the register)

-

8.17. Is there an appropriate decanting system in place for hazardous substances?

-

8.18. Is a spill kit available?

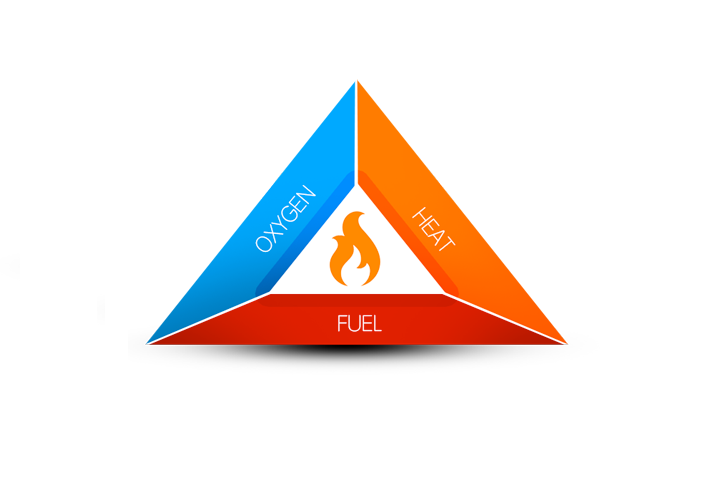

9. Fire protection & Emergency Response

-

9.1. Are written procedures / plans in place and current?<br>

-

9.2. Are emergency procedures displayed on site?

-

9.3. Does a minimum of 2 practice drills occur per year?

-

9.4. Is there any unsuitable or inadequate communication equipment?

-

9.5. Are inspection tests up to date for: Fire extinguisher & Hose reels?

-

9.6. Is Fire equipment marked with a location and identification marker?

-

9.7. Are all Fire extinguishers accessible and clear from obstruction?

-

9.8. Are assembly areas allocated and understood?

-

9.10. Are warning systems clear (Audible) in all areas?

-

9.11. Are all exits kept clear?

10. First Aid

-

10.1 Are sufficient first aid kits available at the workplace?

-

10.2. Are first aid kits checked on a regular basis?

-

10.3. Is all content in date? (Check expiry dates)

-

10.4. Do the contents of the kits agree with the content list?

-

10.5. Are first aid officers identities displayed?

-

10.6. Are emergency telephone numbers displayed?

-

10.7. Are all injuries reported and recorded? (View books and forms)

-

10.8. When first aid equipment is used, is it recorded?

-

10.9 Is a sharps kit available?

11. Traffic Management

-

11.1. Is there a sufficient Traffic Management Plan (TMP) in place?

-

11.2. Has all persons on site been given training for TMP?<br>(Inc contractors and visitors)

-

11.3. Is there sufficient controls for TMP? (physical barriers, bollards, speed limits, flashing lights, spotters, etc)

12. Personal Protective Equipment (PPE)

-

12.1. Is appropriate PPE available and being used and maintained correctly?

-

12.2 Is adequate signage in place where PPE is required to be used?

-

12.3. Is all PPE maintained in good condition?

-

12.4. Are respirators stored correctly?

-

12.5. Is there a system in place to issue, inspect, replace and monitor PPE?

-

12.6. Has appropriate training been given in safe use, clean up and inspection of PPE?

13. Electrical Hazards

-

13.1. Is electrical equipment tested and tagged on a regular basis?

-

13.2. Is the workshop protected by Residual Current Device's (RCD)

-

13.3. Are RCD's manually tested to ensure correct operation?

-

13.4. Are correct power boards used? (No double adaptors or piggy back plugs)

-

13.5. Is clear access provided to switchboards?

-

13.6. Are switchboards in good condition?

-

13.7. Are there contact with underground assets?

-

13.8. Is there contact with overhead electrical lines?

-

13.9. Are leads placed on the ground or on metal structures?

-

13.10. Is there electrical equipment near water?

-

13.11. Is electrical equipment near flammable?

-

13.12. Are electrical equipment near chemicals that could cause damaged?

-

13.13. Are electrical leads in contact with moving machinery parts?

-

13.14 are electrical leads on work surfaces?

-

13.15. Are there LOTO (Lock-Out/Tag-Out) procedures for electrical equipment?

14. Environmental Hazards

-

14.1. Is a Environmental Management plan (EMP) in place?

-

14.2. Is there a dust suppression system?

-

14.3. Is a system in place to prevent contaminants entering stormwater drains?

-

14.4. Is a water re-use system in place?

15. Work Environment

-

15.1. Are washroom and lunchroom facilities available?

-

15.2. Is there sufficient lighting?

-

15.3. Is the outside area kept clean and tidy?

16. Noise

-

16.1. Is the hearing protection provided appropriate for the level of noise emitted?

-

16.2. Are earmuffs correctly maintained? (Check some earmuffs)

17. Signage

-

17.1. Are relevant signs displayed near equipment?

-

17.2. Are unauthorised entry signs displayed?

-

17.3. Are signs in good condition? (Not faded)

-

17.4. Are sufficient signs in use - internally and externally?

-

17.5. Are out of service / danger tags available for use?

18. Administrative Procedures

-

18.1. Is the WH&S policy displayed?

-

18.2. Is the Rehabilitation Policy displayed?

-

18.3. Is the emergency evacuation plan or procedure displayed?

-

18.4. Is there a sufficient induction for workers, contractors and visitors?

-

18.5. Is there sufficient supervisory arrangements?

-

18.6. Is there sufficient training, licences, skills & experiences?

-

18.7. Is there a Safe Work Method Statement for high risk work?

-

18.8. Is there a incident notification procedure?

-

18.9. Is there sufficient routine, inspections, monitoring & audits?

19. General

-

19.1 Are all work areas maintained in a clean and tidy state?

-

19.2. Are scrap metal bins provided and does regular waste removal occur?

-

19.3. Are there adequate storage facilities?

-

19.4. Do staff use good stacking and storage practices?

-

19.5. Are items stored in their designated areas in the storage facilities provided?

-

19.6. Are isles kept clear at all times? (No trip hazards)

-

19.7. Are incident / injury forms available?

-

19.8. Are hazard report forms available?

-

19.9. Are barriers / guards adequate to prevent fall hazards?

-

19.10. Are risk assessments carried out on the use of plant equipment?

20. Other

-

20.1.

-

20.2.

Corrective Actions

-

Enter any corrective actions that will be undertaken

Sign Off

-

On site representative

-

Auditor's signature