Title Page

-

Site conducted

-

Conducted on

-

Prepared by

Questionnaire

-

Applicants name?

-

Phone Number?

-

Email?

-

What is your experience driving HC vehicles?

-

Do you have any experience with computers and programs like operating faceplates, weighbridge systems, Ipads/tablet related work apps?

-

The mill operates 24 hours a day from 11pm Sunday night shift to 11pm Friday afternoon. We run a weekly rotating shift starting with day shift around 4am to 12pm, then afternoon shift starting from 4pm to 12am. Do you have any Experience in shift work as it is a requirement of the role?

-

What current Work permits/licenses do you hold? e.g. HC, MC, Forklift, Front End Loader, Working at Heights, confined space?

-

Truck driving shifts work around 8-to-10-hour shifts, this will consist of an average of 4 loads per day with an average turnaround of approximately 2 hours per load. Time management skills are very important. Have you had a similar work experience with time management?

-

Safety is a big component on Rivalea sites., Do you have any safety training like safety officer, HSR, first aid, warden? and do you have experience filling out JSA's or work records?

-

Are you available for overtime if required?

-

Due to the changing demand of feed, some days drivers will be required to perform some cleaning tasks like, hosing, washing trucks, street sweeping, etc, when the load demand is low. Do you understand and agree to perform these tasks as required.

-

Employee Signature

Feedmill Tour

Laboratory

-

The lab is our quality assurance area ran by 2 trained technicians. their roles include testing of raw material and finished product ensuring all our incoming raw materials, ground grain, and outgoing finished product is within required specs. A variety of tests are concluded on raw material and finished product using our FOSS system that tests protein, moisture, fats, ash. other manual tests like durability and fines of finished product are also conducted to ensure the product meets standards.

-

Mill operatives will take over lab duties at 5pm when the technicians are finished for the day. It is part of the weighbridge duties to ensure all feed is tested before it leaves site.

Out Loading Area

-

The out loading bin area is where all outwards feed is loaded from. This consists of a two laneway access road with 30 bins, some of which can hold up to 60 tons of feed. Bins 1-4, 5-8, 19-24, 25-30 are located on the left hand side. Bins 9-12, 13-16, and 17-18 are located on the right hand side. A variety of different freight and logistic companies load here daily, about 70% of our feed is made for our internal piggeries, while the rest is divided between contract sites and free trade customers.

Control Room

-

The control room is the central office located in the production building. This is a specialized area run by shift supervisors who task it is to batch all the feed produced in the Feedmill. This is a highly skilled area requiring attention to detail and supervision of many moving parts. This oversees the two main production areas of Soft Intake, and the Press Floor. Shift supervisors are responsible for all of our finished product to be batched , Pressed and ready for pick up as well as overseeing raw material levels and grinding systems.

Soft Intake

-

The soft intake is our area focused on keeping the feedmill running. Its main role is to fill raw materials in our Macro and Micro fill stations. these stations are located in warehouse 1 attached to the main building and outside in our soft intake meals pit. The mill runs 24 hours a day, 5 days a week, so soft intake operators are to ensure all stocks are kept at the required levels for weekly production. Other duties include assisting in pressfloor operations, restocking pressfloor, clearing of finished product bins & the flushing RAM products.

Pressfloor

-

The Pressfloor is our preferred starting area for our mill operatives. Its a crucial role that shows our steam pelletizing process. The role of the press operator is to monitor 3 pelleting presses, ensuring the pellet quality meets our standards and correct hand additives and medications are added to the feed. Maintenance and meeting cleaning standards is another vital role that press operators must complete on all machinery and equipment, this ensures our pelleting systems are running efficiently.

Warehousing

-

There are 3 warehouses located throughout the feedmill, warehouse 2, and 3 store the bulk of our Macro and Micro tipped products. The warehouse operators role is to unload and load trucks, ensure all incoming products are correctly labeled and stored.

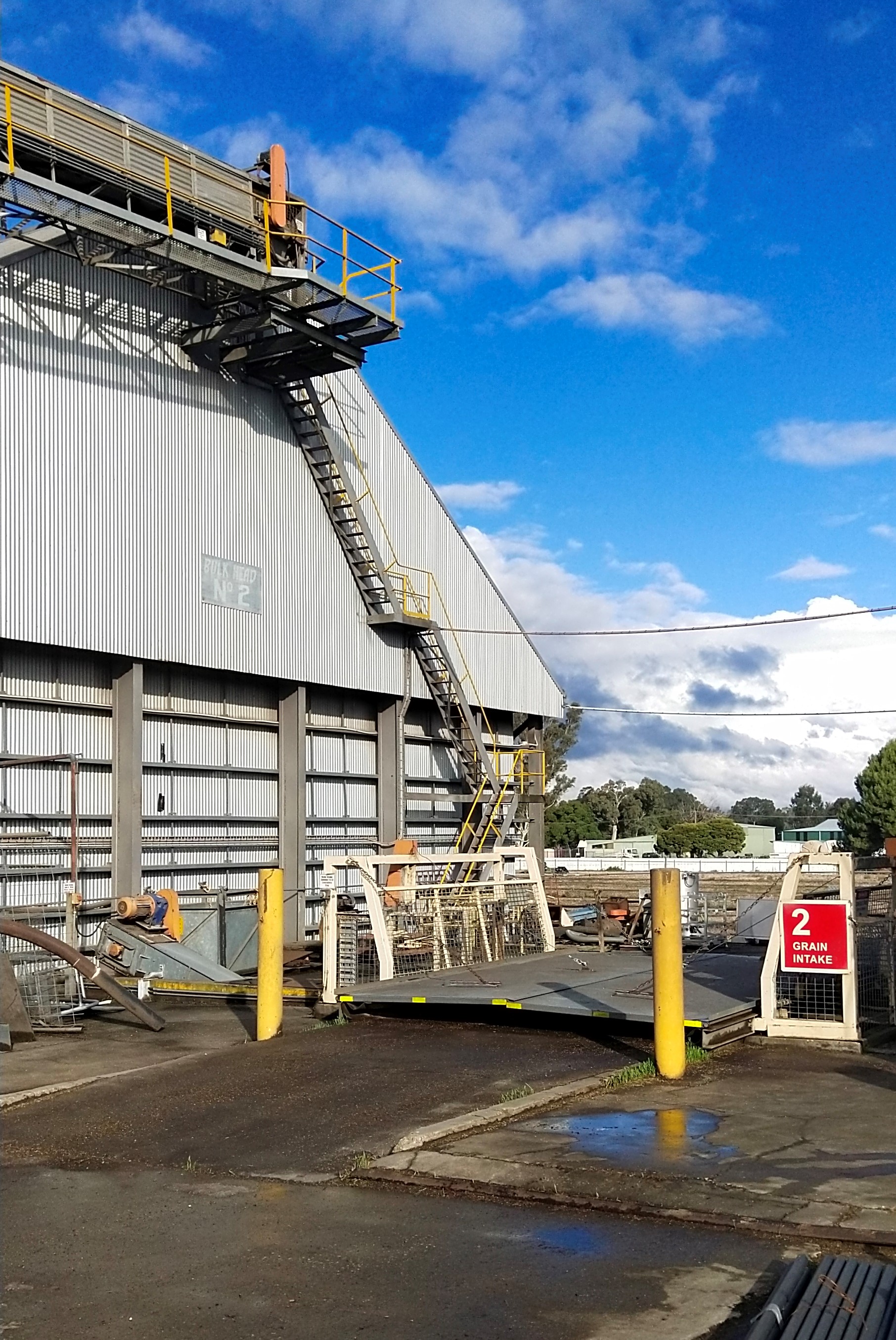

Weighbridge

-

The weighbridge is one of our most important roles, its the first point of contact for all incoming deliveries, managing traffic efficiently and safely is a crucial component of this role. Weighbridge incorporates a variety of tasks, including managing grain intake systems, testing grain quality, data entry, Lab work and administrative duties.

Amenities

-

Add drawing

Smoking Areas

-

• The Corowa feedmill has two smoking areas, it is now a requirement of all employees they only smoke in these designated areas.

-

• The first smoking area is located directly behind the weighbridge this area is clearly marked

-

• The second smoking area is located at the end of the office towards warehouse 3 this area is clearly marked

-

It is the responsibilty of all smokers to keep this area clean and tidy this includes the emptying of ash trays. Cigarette butts must not be left on the ground in these locations

-

Smoking in prohibited areas can result in disciplinary actions or the banning of smoking on-site.