Title Page

-

Site conducted

-

Conducted on:

-

Prepared by / Position:

-

Responsible Person / Manager at Branch:

Monthly checklist of all RPE in branch

-

When answering any questions on the checklist please read the 'guide' aspect on each one before answering 'yes' or 'no', this guide will instruct on each thing to check / evidence within the question. Images of certain items on the E3000X will accompany the guide for reference also.

-

Have any actions from the previous RPE - RESPIRATORY PROTECTIVE EQUIPMENT (MONTHLY CHECKLIST) been completed / closed out?

-

Review actions with user / foremen & branch manager - look to resolve actions ASAP. Speak with Head of Region, SHEQ or HTS for assistance with any issues.

-

Select a unit:

- Spraying Shop

- Welding Shop

- Fitters Van

SPRAYING SHOP

-

Set

RPE – RAPR E3000X (visual checks)

-

During arc welding, grinding and many other dust-intensive activities such as spray painting, your respiratory tract is always exposed to harmful smoke, dusts and often toxic gases. Wearing a personal respiratory protection system is therefore essential, no matter how good your working environment is ventilated

-

Is the air hose intact?

-

(Check for burns / holes or melted areas)

-

Are the hose clips both functioning correctly?

-

(check for broken clips / air escaping from base & that the clips are tight - it does not matter which end goes in which they are the same both ends)

-

Is the leather belt in good working order?

-

(check for splits / buckle damage)

-

Is the cover plate in one piece?

-

(check for burns / damage & sharp edges)

-

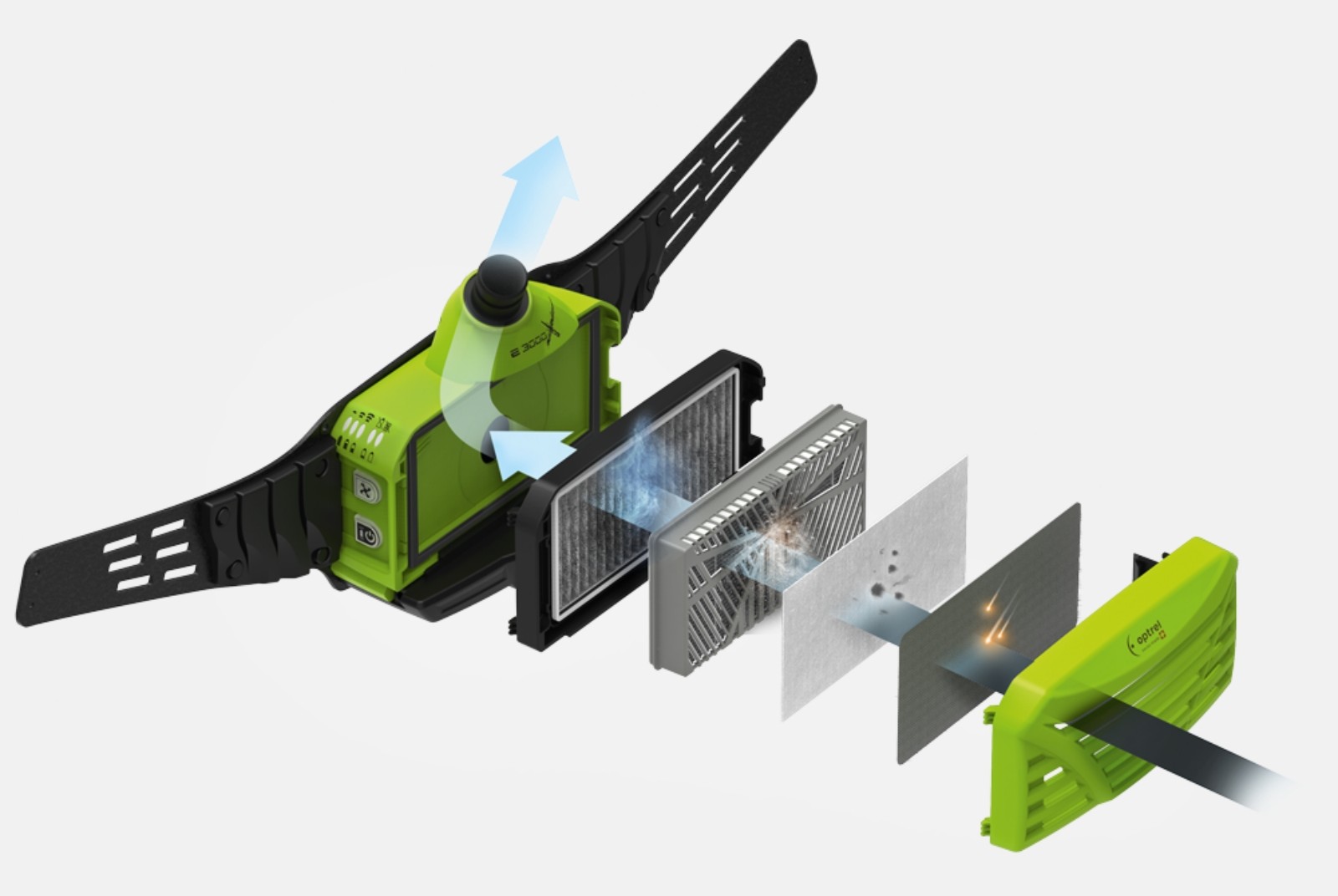

Next questions look at the filters within the unit - main area of concern for the service plan rollout conducted in early 2021 that these safety critical items were not fitted / changed correctly causing issues with the overall performance.

-

Is the main filter intact?

-

(check this is working correctly, the filter shouldn't be totally free from dust / particles that's its purpose to capture this, the alarm will signal if its performing below capacity - change if required. The filter covers the worker at the highest possible level - TH3-certified breathing protection systems filter 10 times more dirt out of the air, or in other words: 99.8% of the harmful particles are filtered out of the air.)

-

Is the pre-filter clean & free from debris?

-

(check the location is correct – between spark arrestor & main filter / the filter shouldn't be totally free from dust / particles that's its purpose to capture this, the alarm will signal if its performing below capacity - change if required)

-

Is the spark arrester in good condition?

-

(check the spark arrestor – thin wire mesh is against the outer cover plate & not clogged up, this will protect against sparks / flames entering the unit, the first line of defence – change if required)

-

Is the main housing seal in good condition?

-

(check the black foam strip along the inner case is free from splits / damage)

-

This RAPR E3000X unit is vital to the maintenance & safe operation in the branch. It's critical that the user is fully protected at all times, the monthly checks should be performed in conjunction with the operative to enhance the understanding from all persons.

RPE - RAPR E3000X (functioning checks)

-

Is the battery sufficiently charged?

-

(check the battery for damage / cracks – make sure the charger is working, the unit will be fully charged in 4 hours & will last for 8-20 hours depending on the air flow levels used)

-

Is the blower working correctly?

-

(check the unit is blowing air up through the filters into the hose / system by using your hand)

-

Can the switch fan speed be changed up / down to 1-2-3?

-

(the LED lights will show the different air flow levels – 1 = 170 litres per minute / 2 = 210 lpm / 3 = 240 lpm)

-

Do all the LEDs work?

-

(check the lights on the unit are in working order – to ensure correct personal air flow is being utilised)

RPE - ClearMaxx helmet (spraying & grinding)

-

Instruction to the operative from supervisor: the helmet should be checked DAILY before use - check the clear lens for damage and replace when needed / Check the air inlet valve is not blocked / Check the face seal for damage, look out for cuts and holes, replace If needed. This will ensure maximum protection on a daily basis ahead of the monthly checklist.

-

Is the face seal intact?

-

(check the elastic / face seal is not perished or dirty)

-

Are the headgear / sweatbands in good condition?

-

(change the sweatband if required using Velcro)

-

Is the helmet shell intact?

-

(check for cracks / damage from sparks & no over-spray / dust is present)

-

Is the helmet lens intact & in good condition?

-

(check for cracks / damage)

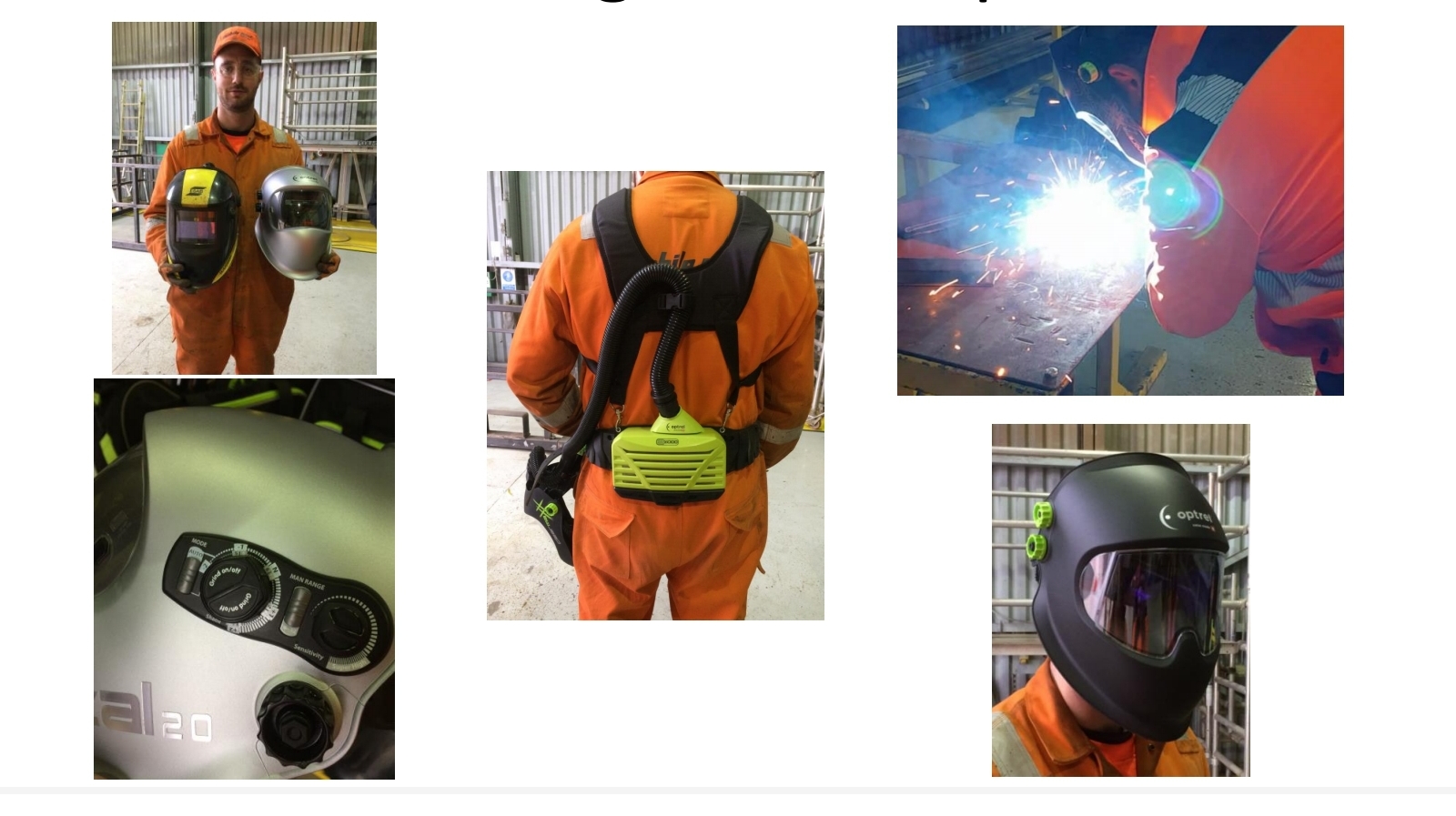

Photographs of all elements / parts of the Optrel system/s in branch

-

Base unit / battery

-

Hose

-

Helmet

Storage of system

-

Is the system (helmet / hose & unit) stored away from dust in a clean dry place?

-

(check the system is stowed away – preferably in the Optrel sports bag it came in)

-

Is the system cleaned regularly using wipes?

-

(Instruction to operative: check it’s overall condition – regular cleaning with maximize efficiency & prolong life of product, The system should be cleaned with a damp cloth, never submerge the system in water, you may use mild disinfection solution, once cleaned dry with a clean cloth)

Photograph of Optrel system when not in use / storage (clean & dry location)

-

stored in Optrel bag / cabinet / box away from work area

Training of users on Optrel system

-

Are all users trained to use the system?

-

(check with Josh Aston & HTS if required – training can be facilitated online via HTS / SHEQ or given through Halogen portal)

-

Do the users have any issues with using the system?

-

(check the tasks they’re using the system for are in line with the products parameters – contact SHEQ or HTS for further guidance of required)

-

NO-ONE should use this safety critical equipment without the relevant training / refreshers. It is imperative those conducting the monthly checklist & those using are confident with the working / set-up of the kit - misuse or neglect could lead to disciplinary proceedings against the individual.

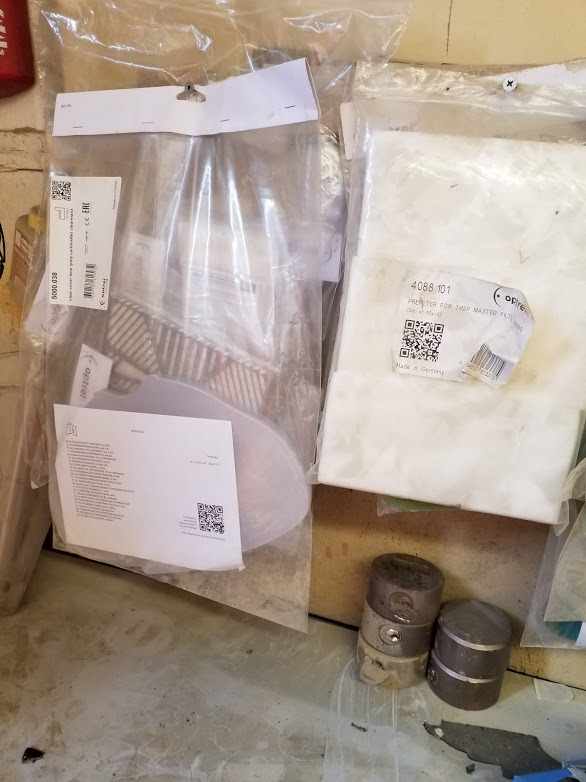

Supplies of Optrel products in branch

-

Are there sufficient supplies in the branch?

-

(check spark arrestors / pre filters / main filters – lenses are readily available in branch store should they be required – contact HTS for back-up supplies)

-

Do staff have access to HTS portal in branch?

-

(check a designated person/s have ease of access to the portal to order essential stocks when needed)

-

Take a photo of stock levels in clean dry place within branch

Statement / Signature

-

I confirm that all of the information above is correct at time of reporting, and that the form has been completed at the point of work incorporating the user.

-

Sign Off:

WELDING SHOP

-

Set

RPE – RAPR E3000X (visual checks)

-

During arc welding, grinding and many other dust-intensive activities such as spray painting, your respiratory tract is always exposed to harmful smoke, dusts and often toxic gases. Wearing a personal respiratory protection system is therefore essential, no matter how good your working environment is ventilated

-

Is the air hose intact?

-

(Check for burns / holes or melted areas)

-

Are the hose clips both functioning correctly?

-

(check for broken clips / air escaping from base & that the clips are tight - it does not matter which end goes in which they are the same both ends)

-

Is the leather belt in good working order?

-

(check for splits / buckle damage)

-

Is the cover plate in one piece?

-

(check for burns / damage & sharp edges)

-

Next questions look at the filters within the unit - main area of concern for the service plan rollout conducted in early 2021 that these safety critical items were not fitted / changed correctly causing issues with the overall performance.

-

Is the main filter intact?

-

(check this is working correctly, the filter shouldn't be totally free from dust / particles that's its purpose to capture this, the alarm will signal if its performing below capacity - change if required. The filter covers the worker at the highest possible level - TH3-certified breathing protection systems filter 10 times more dirt out of the air, or in other words: 99.8% of the harmful particles are filtered out of the air.)

-

Is the pre-filter clean & free from debris?

-

(check the location is correct – between spark arrestor & main filter / the filter shouldn't be totally free from dust / particles that's its purpose to capture this, the alarm will signal if its performing below capacity - change if required)

-

Is the spark arrester in good condition?

-

(check the spark arrestor – thin wire mesh is against the outer cover plate & not clogged up, this will protect against sparks / flames entering the unit, the first line of defence – change if required)

-

Is the main housing seal in good condition?

-

(check the black foam strip along the inner case is free from splits / damage)

-

This RAPR E3000X unit is vital to the maintenance & safe operation in the branch. It's critical that the user is fully protected at all times, the monthly checks should be performed in conjunction with the operative to enhance the understanding from all persons.

RPE - RAPR E3000X (functioning checks)

-

Is the battery sufficiently charged?

-

(check the battery for damage / cracks – make sure the charger is working, the unit will be fully charged in 4 hours & will last for 8-20 hours depending on the air flow levels used)

-

Is the blower working correctly?

-

(check the unit is blowing air up through the filters into the hose / system by using your hand)

-

Can the switch fan speed be changed up / down to 1-2-3?

-

(the LED lights will show the different air flow levels – 1 = 170 litres per minute / 2 = 210 lpm / 3 = 240 lpm)

-

Do all the LEDs work?

-

(check the lights on the unit are in working order – to ensure correct personal air flow is being utilised)

Photographs of all elements / parts of the Optrel system/s in branch

-

Base unit / battery

-

Hose

-

Helmet

Storage of system

-

Is the system (helmet / hose & unit) stored away from dust in a clean dry place?

-

(check the system is stowed away – preferably in the Optrel sports bag it came in)

-

Is the system cleaned regularly using wipes?

-

(Instruction to operative: check it’s overall condition – regular cleaning with maximize efficiency & prolong life of product, The system should be cleaned with a damp cloth, never submerge the system in water, you may use mild disinfection solution, once cleaned dry with a clean cloth)

Photograph of Optrel system when not in use / storage (clean & dry location)

-

stored in Optrel bag / cabinet / box away from work area

Training of users on Optrel system

-

Are all users trained to use the system?

-

(check with Josh Aston & HTS if required – training can be facilitated online via HTS / SHEQ or given through Halogen portal)

-

Do the users have any issues with using the system?

-

(check the tasks they’re using the system for are in line with the products parameters – contact SHEQ or HTS for further guidance of required)

-

NO-ONE should use this safety critical equipment without the relevant training / refreshers. It is imperative those conducting the monthly checklist & those using are confident with the working / set-up of the kit - misuse or neglect could lead to disciplinary proceedings against the individual.

Supplies of Optrel products in branch

-

Are there sufficient supplies in the branch?

-

(check spark arrestors / pre filters / main filters – lenses are readily available in branch store should they be required – contact HTS for back-up supplies)

-

Do staff have access to HTS portal in branch?

-

(check a designated person/s have ease of access to the portal to order essential stocks when needed)

-

Take a photo of stock levels in clean dry place within branch

RPE - Panoramaxx Helmet (Welding & Grinding)

-

Instruction to the operative from supervisor: the helmet should be checked DAILY before use - check the outer & inner lens for damage and replace when needed / Check the air inlet valve is not blocked / Check the face seal for damage, look out for cuts and holes, replace if needed. This will ensure maximum protection on a daily basis ahead of the monthly checklist.

-

Is the helmet USB lead intact & working correctly?

-

(check the charger is working & used in a clean dry location)

-

Is the green light at the front of the helmet working correctly?

-

(check the green light is illuminated - this means the unit is charged)

-

Is the nose pad intact & comfortable?

-

(check with the wearer there's no damage or splits in the pad - replace if required)

-

Is the headband / attachment intact & free from damage?

-

(check & adjust head band to suit (including the tilt button) helmet should sit just above the nose, adjust the lens as close to eyes as possible to maximise field of vision - replace headband using velcro if required)

-

Does the autopilot feature work?

-

(check the auto / buttons are functioning correctly - the green button should be in the N position)

-

Can the brightness be changed up or down?

-

start welding and adjust + or – depending on clarity and brightness (this has now set the lens perfect for your eyes) no further adjustment is needed

-

Can the sensitivity be changed to suit the wearer?

-

(adjust sensitivity according to the environment (away from the superhigh setting is advised if not welding low amps)

Statement / Signature

-

I confirm that all of the information above is correct at time of reporting, and that the form has been completed at the point of work incorporating the user.

-

Sign Off:

FITTERS VAN

-

Set

RPE – RAPR E3000X (visual checks)

-

During arc welding, grinding and many other dust-intensive activities such as spray painting, your respiratory tract is always exposed to harmful smoke, dusts and often toxic gases. Wearing a personal respiratory protection system is therefore essential, no matter how good your working environment is ventilated

-

Is the air hose intact?

-

(Check for burns / holes or melted areas)

-

Are the hose clips both functioning correctly?

-

(check for broken clips / air escaping from base & that the clips are tight - it does not matter which end goes in which they are the same both ends)

-

Is the leather belt in good working order?

-

(check for splits / buckle damage)

-

Is the cover plate in one piece?

-

(check for burns / damage & sharp edges)

-

Next questions look at the filters within the unit - main area of concern for the service plan rollout conducted in early 2021 that these safety critical items were not fitted / changed correctly causing issues with the overall performance.

-

Is the main filter intact?

-

(check this is working correctly, the filter shouldn't be totally free from dust / particles that's its purpose to capture this, the alarm will signal if its performing below capacity - change if required. The filter covers the worker at the highest possible level - TH3-certified breathing protection systems filter 10 times more dirt out of the air, or in other words: 99.8% of the harmful particles are filtered out of the air.)

-

Is the pre-filter clean & free from debris?

-

(check the location is correct – between spark arrestor & main filter / the filter shouldn't be totally free from dust / particles that's its purpose to capture this, the alarm will signal if its performing below capacity - change if required)

-

Is the spark arrester in good condition?

-

(check the spark arrestor – thin wire mesh is against the outer cover plate & not clogged up, this will protect against sparks / flames entering the unit, the first line of defence – change if required)

-

Is the main housing seal in good condition?

-

(check the black foam strip along the inner case is free from splits / damage)

-

This RAPR E3000X unit is vital to the maintenance & safe operation in the branch. It's critical that the user is fully protected at all times, the monthly checks should be performed in conjunction with the operative to enhance the understanding from all persons.

RPE - RAPR E3000X (functioning checks)

-

Is the battery sufficiently charged?

-

(check the battery for damage / cracks – make sure the charger is working, the unit will be fully charged in 4 hours & will last for 8-20 hours depending on the air flow levels used)

-

Is the blower working correctly?

-

(check the unit is blowing air up through the filters into the hose / system by using your hand)

-

Can the switch fan speed be changed up / down to 1-2-3?

-

(the LED lights will show the different air flow levels – 1 = 170 litres per minute / 2 = 210 lpm / 3 = 240 lpm)

-

Do all the LEDs work?

-

(check the lights on the unit are in working order – to ensure correct personal air flow is being utilised)

RPE - ClearMaxx helmet (spraying & grinding)

-

Instruction to the operative from supervisor: the helmet should be checked DAILY before use - check the clear lens for damage and replace when needed / Check the air inlet valve is not blocked / Check the face seal for damage, look out for cuts and holes, replace If needed. This will ensure maximum protection on a daily basis ahead of the monthly checklist.

-

Is the face seal intact?

-

(check the elastic / face seal is not perished or dirty)

-

Are the headgear / sweatbands in good condition?

-

(change the sweatband if required using Velcro)

-

Is the helmet shell intact?

-

(check for cracks / damage from sparks & no over-spray / dust is present)

-

Is the helmet lens intact & in good condition?

-

(check for cracks / damage)

Photographs of all elements / parts of the Optrel system/s in branch

-

Base unit / battery

-

Hose

-

Helmet

Storage of system

-

Is the system (helmet / hose & unit) stored away from dust in a clean dry place?

-

(check the system is stowed away – preferably in the Optrel sports bag it came in)

-

Is the system cleaned regularly using wipes?

-

(Instruction to operative: check it’s overall condition – regular cleaning with maximize efficiency & prolong life of product, The system should be cleaned with a damp cloth, never submerge the system in water, you may use mild disinfection solution, once cleaned dry with a clean cloth)

Photograph of Optrel system when not in use / storage (clean & dry location)

-

stored in Optrel bag / cabinet / box away from work area

Training of users on Optrel system

-

Are all users trained to use the system?

-

(check with Josh Aston & HTS if required – training can be facilitated online via HTS / SHEQ or given through Halogen portal)

-

Do the users have any issues with using the system?

-

(check the tasks they’re using the system for are in line with the products parameters – contact SHEQ or HTS for further guidance of required)

-

NO-ONE should use this safety critical equipment without the relevant training / refreshers. It is imperative those conducting the monthly checklist & those using are confident with the working / set-up of the kit - misuse or neglect could lead to disciplinary proceedings against the individual.

Supplies of Optrel products in branch

-

Are there sufficient supplies in the branch?

-

(check spark arrestors / pre filters / main filters – lenses are readily available in branch store should they be required – contact HTS for back-up supplies)

-

Do staff have access to HTS portal in branch?

-

(check a designated person/s have ease of access to the portal to order essential stocks when needed)

-

Take a photo of stock levels in clean dry place within branch

RPE - Panoramaxx Helmet (Welding & Grinding)

-

Instruction to the operative from supervisor: the helmet should be checked DAILY before use - check the outer & inner lens for damage and replace when needed / Check the air inlet valve is not blocked / Check the face seal for damage, look out for cuts and holes, replace If needed. This will ensure maximum protection on a daily basis ahead of the monthly checklist.

-

Is the helmet USB lead intact & working correctly?

-

(check the charger is working & used in a clean dry location)

-

Is the green light at the front of the helmet working correctly?

-

(check the green light is illuminated - this means the unit is charged)

-

Is the nose pad intact & comfortable?

-

(check with the wearer there's no damage or splits in the pad - replace if required)

-

Is the headband / attachment intact & free from damage?

-

(check & adjust head band to suit (including the tilt button) helmet should sit just above the nose, adjust the lens as close to eyes as possible to maximise field of vision - replace headband using velcro if required)

-

Does the autopilot feature work?

-

(check the auto / buttons are functioning correctly - the green button should be in the N position)

-

Can the brightness be changed up or down?

-

start welding and adjust + or – depending on clarity and brightness (this has now set the lens perfect for your eyes) no further adjustment is needed

-

Can the sensitivity be changed to suit the wearer?

-

(adjust sensitivity according to the environment (away from the superhigh setting is advised if not welding low amps)

-

Is the green light at the front of the helmet working correctly?

-

(check the green light is charged)

Statement / Signature

-

I confirm that all of the information above is correct at time of reporting, and that the form has been completed at the point of work incorporating the user.

-

Sign Off: