Information

-

Audit Title

-

Client / Site

-

Conducted on

-

Prepared by

-

Location

-

Personnel

-

Document No.

1.0 - Previous inspection

-

1.1 - Has the last inspection been reviewed?

-

1.2 - Is this a design scaffolding?

2.0 - Foundations

-

2.1 - Ground conditions can take the weight of the scaffolding

-

2.2 - No evidence of sinkage

-

2.3 - Scaffolding not erected on manhole covers

-

2.4 - Scaffolding not erected over excavations

-

2.5 - scaffolding not erected near trenches

3.0 - Footings ( Base Plate & Sole Boards )

-

3.1 - Are sole boards fitted

-

3.2 - Are sole boards he correct dimensions

-

3.3 - Are base plates fitted correctly

-

3.4 The footing have not been moved ?

-

3.5 - The footings are not damaged

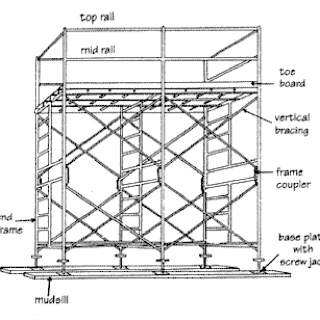

4.0 - Standards

-

4.1 - Are standards free from damage ?

-

4.2 - Are standards vertical ; Plum ?

-

4.3 Are standards correctly spaced ( as per design or TG20 )

-

4.4 Are couplers tight ?

-

4.5 - Are couplers ( sleeves ; joints ) staggered ?

5.0 - Ledgers

-

5.1 - Are he ledgers Horizontal ?

-

5.2 - Are the ledgers free from damage ?

-

5.3 have right angle couplers been used ?

-

5.4 - Are joints staggered ?

-

5.5 Are couplers tight ?

6.0 - Transoms

-

6.1 - Are Transoms horizontal?

-

6.2 - are Transoms free from damage ?

-

6.3 - Have right angle couplers used (as required) ?

-

6.4 - Are transom spacing correct for support of the board and as per design ?

-

6.5 - tubes are at least 50mm pass the coupler?

-

6.6 - is the working platform wide enough and to design ?

7.0 - Edge Protection & General Protection

-

7.1 - top rail fitted at correct height?

-

7.2 - Intermediate rails fitted at the correct height?

-

7.3 - toe boards fitted to all elevations including haki staircases

-

7.4 - Gates and operable?

-

7.5 - Edge protection secured and undamaged. <br>

-

7.6 - Trapdoors fitted in platforms were applicable?

8.0 - Boards

-

8.1 are boards free from all defects?

-

8.2 - Are all boards still in the correct position and not be tampered by others on site ?

-

8.3 - are boards secured where applicable?

-

8.4 - Are boards correctly supported by the Transoms?

-

8.5 - Are boards placed so they don't cause slips , trips and falls ?

9.0 - Bracing

-

9.1 Facade bracing been fitted correctly?

-

9.2 - Ledger bracing been fitted correctly?

-

9.3 - Plan bracing fitted where applicable

-

9.4 - If rackers are fitted are they correct and tied back to standards?

-

9.5 - Are all the couplers tight?

-

9.6 - Are correct couplers fitted?

10.0 - Ladders

-

10.1 - Are the ladders adequate length and raise above the platform 1.05mtrs?

-

10.2 - Are ladders correctly secured?

-

10.3 - Are all ladders undamaged?

-

10.4 - have ladders been inspected within the last three months?

-

10.5 - Are all ladders set at the correct angle i.e 1 to 4

11.0 - Security and Protection

-

11.1 - is public protection adequate?

-

11.2 - is the means to prevent access adequate ?

-

11.3 - scaffolding does not encroach into roadway?

-

11.4 - safe passage available to the public

-

10.5 Signage adequate and fixed into place?

12.0 Ties

-

12.1 - Are ties fitted to right angle couplers ,

-

12.2 - Are the right angle couplers secure and tight

-

12.3 - is pull testing up-to date as per company policy ( 10 percent) ?.

-

12.4 - Is he tie certification in the site health and safety folder?

-

12.5 - Have ties been fitted as per scaffolding design ?

-

12.6 - Are tie spacing correct ?

13.0 Miscellaneous

-

13.1 Last inspection completed within the last 7 days

-

13.2 scaffolding structure has been designed and erected to the specification ?

-

13.3 - SWL of scaffolding has not been exceeded?

-

13.4 - monarflex / debris netting fitted correctly and tidy ?

Quality Inspection Check sheet

-

Have all Actions been closed out from the previous visit , if not detail those outstanding!

-

Pre start briefing have been done ?

-

Have all personnel completed Alandale Plant & Scaffolding induction form and entered it on the induction register?

-

Training records - CISRS / CSCS cards are all up to date on site and a copy kept in the health and safety folder?

-

Does the site supervisor have adequate qualifications and experience to run the site safety ?

-

Does the site have adequate cover on site when Alandale Site Supervisor is off?

-

RAMS have been reviewed within the last 6 Months and or still adequate and task/risk specific?

-

Has harness inspections been carried within the last 7 days and inspection records available in the site health and safety folder?

-

Are harness been worn correctly by operatives ?

-

Power Tools on site are in good condition and have been PAT Tested and are in date?

-

Does the lorry have a lifting plan when on site , does he require one ?

-

Is house keeping on site to a good standard ?

-

Scaffolding tie pull test required ?

-

Is the welfare facilities on site to a good standard and conform to the HSAW act ?

-

Warning signs have been erected i.e locations and elevations.

-

Design Drawings available for construction including design briefing details on drawing register?

-

Have there been any accidents on this project since commencement

-

Are the QSE plans located within the site health and safety folder?

-

Are the QHSE policy located within the site health and safety folder.

-

Has a toolbox talk been carried out in the past seven days , if so detail with the number of attendees. <br>

-

Is the PPE register being maintained with dates of equipment usage ?

-

Are all scaffolding operatives been issued with tether tools ?

-

Has a client satisfaction questionnaire been used to the client within the last 6months ?

14.0 - Details of issues arising from this scaffolding inspection

-

14.1. Recommendations/Personal Responsible /Target Date

15.0 - details of actions to be taken.

-

15.1 - Details of actions taken by competent persons to rectify issues/ date / completed

Sign Off

-

On site representative

-

Auditor's signature