Title Page

-

Site conducted

-

Conducted on

-

Inspected by

-

Equipment Owner

Checklist

Full Body Harness

-

Harness Model & Manufacturing Date

-

Serial Number & Lot Number

-

Harness Size

-

-

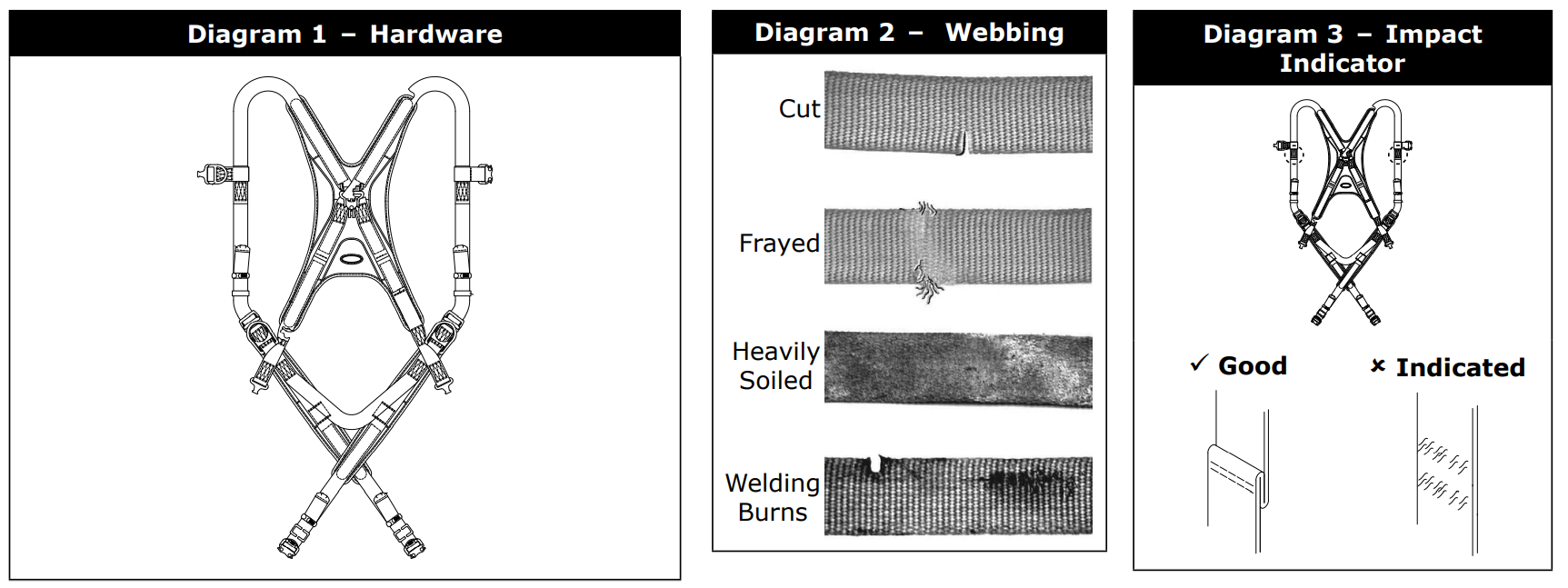

Harness Hardware: (Diagram 1) Inspect harness hardware including buckles, adjusters, D-rings, Easy-Link, loop keepers, lanyard parking, etc. These items must not be damaged, broken, or distorted, and must be free of sharp edges, burrs, cracks, worn parts, or corrosion. PVC coated hardware must be free of cuts, rips, tears, holes, etc. in the coating to ensure non-conductivity. Ensure buckles and adjusters work smoothly.

-

Webbing & Stitching: (Diagram 2) Inspect webbing; material must be free of frayed, cut, or broken fibers. Check for tears, abrasions, mold, burns, or discoloration. Inspect stitching; Check for pulled or cut stitches. Broken stitches may be an indication that the harness has been impact loaded and must be removed from service.

-

The Stitched Impact Indicators: (Diagram 3) These are sections of webbing lapped back on themselves and secured with a specific stitch pattern. The stitch pattern is designed to release when the harness arrests a fall or is exposed to equivalent force. If an Impact Indicator has been activated (indicated), the harness must be removed from service and destroyed.

-

Labels: Inspect, make certain all labels are securely held in place and legible.

D-Ring Extender

-

D-Ring Extender Model & Manufacturing Date

-

Serial Number & Lot Number

-

Length

-

-

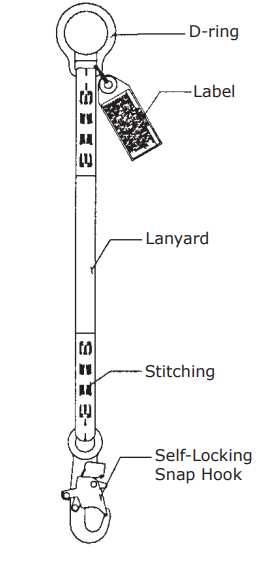

Hardware: (Includes snap hooks, carabiners, adjusters, keepers, thimbles and D-rings). These items must not be damaged, broken, distorted, or have any sharp edges, burrs, cracks, worn parts, or corrosion. Ensure the connecting hooks work properly. The hook gates must move freely and lock upon closing. Ensure the adjusters, if present, work properly.

-

Webbing & Stitching: Inspect the webbing. The material must be free of frayed, cut, or broken fibers. Check for tears, abrasions, mold, burns, or discoloration. Inspect the stitching. Check for pulled or cut stitches. The webbing must be free of knots, excessive soiling, heavy paint buildup, and rust staining. Check for chemical or heat damage, indicated by brown, discolored, or brittle areas. Check for ultraviolet damage, indicated by discoloration and the presence of splinters or slivers on the webbing surface. All of these above factors are known to reduce the webbing strength. Damaged or questionable webbing should be replaced.

-

SYNTHETIC ROPE: Inspect the rope for concentrated wear. The material must be free of frayed or broken strands, cuts, abrasions, burns, and discoloration. The rope must be free of knots, excessive soiling, heavy paint buildup, and rust staining. Rope splices must be tight, with five full tucks, and the thimbles must be held by the splice. Check for chemical or heat damage indicated by brown, discolored, or brittle areas. Check for ultraviolet damage, indicated by discoloration and the presence of splinters and slivers on the rope surface. All of the above factors are known to reduce the rope strength. Damaged or questionable ropes should be replaced

-

Labels: Inspect the labels. All labels must be present and fully legible.

Time & Date of Completion

-

Select date

-

Add signature