Title Page

-

Location of the site

-

Photo of site - Daytime

-

Who is responsible for the site? (Organisation or Persons)

-

Who is the named person responsible for maintenance of the site?

-

Prepared on

-

Prepared by

-

Supported by

Site Information

-

Site description

-

Who is commonly onsite? and in what numbers?

Focus of the Workplace Risk Assessment

-

What is the relationship that has led to this risk assessment being undertaken?

Goal of the Workplace Risk Assessment

-

Why is this workplace risk assessment needed?

-

What is the intended result, effect, or output of this workplace risk assessment?

Headline assessment

-

Is there a pre-existing risk assessment for the site available for inspection?

-

Is a site plan available with all Services marked?

-

Is there a record held of accidents, incidents & near misses for the site?

-

Is the site likely to have Asbestos containing materials?

-

Has an asbestos survey been undertaken?

-

Is the survey current?

-

In the notes please provide more details as to why one has not been completed

-

In the notes please detail why it is believed there are no ACM's onsite and where appropriate upload evidence

-

Is there a Fire Risk Assessment available?

-

Is the FRA current?

-

Please raise an action for the FRA to be updated ASAP and in the notes provide details of when the last FRA was completed

-

Raise an action for a FRA to be completed ASAP

-

Is there Mains Gas onsite?

-

Where is the main gas inlet

-

Is the Gas Shut off value easy accessible and clearly marked?

-

Is there an current Gas Safety Certificate?

-

Is there any Carbon Monoxide monitoring

-

Is there Electricity onsite?

-

Where is the electrical intake?

-

Where is the fuse board?

-

Is the fuse board secure?

-

Has a Fixed Electrical Inspection been carried out in the last 5yrs?

-

Is there Water onsite?

-

Where is the Water Intake?

-

Where is the isolation value inside the building

-

Is the valve easy to access?

-

Is the valve free turning?

-

Is there a legionella risk assessment?

-

Is the risk assessment current?

-

Are there any COSHH Substances onsite?

-

Where all COSHH substances controlled by a COSHH assessment

-

Where all COSHH substances stored in an appropriate manner?

-

Are Material Data Safety Sheets available?

-

Is there a program of site inspections to identify issues?

-

Is there evidence to support the site inspection program?

-

Are the documented procedures for the management of Foreseeable emergencies?

-

Please raise an action for a program of site inspections to be set up

H&S Law

-

Does the controlled of the site have a H&S policy?

-

Is there a H&S Law poster displayed?

-

Is there a site H&S board?

-

Are the relevant insurance policies displayed?

-

Is there a poster which details who to contact for First Aid?

Internal Hazards

Internal

-

Is the lighting sufficient internally throughout the site?

-

Is there a program of inspection to check emergency lighting?

-

All internal surfaces are in good condition

-

All ramps are of a safe gradient and have sufficient friction

-

Are all stairwells in good condition, with sufficient handrails

-

Are door closers used to control the speed / weight of door opening and closing?

-

Are finger guards in place to prevent finger traps on doors?

-

Are there any DSE users onsite

-

Have DSE assessments been completed for all eligible persons?

Fire Risk Monitoring

-

This section covers key aspects for Fire Safety, but does not replace the need for a detailed Fire Risk Assessment to be undertaken by a competent Fire Risk Assessor.

-

Is the Responsible person clearly identified?

-

Fire Extinguishers are present and within service date?

-

Fire Extinghishers are not blocked

-

The assembly point is clearly signed

-

All Evacuation routes lead to a place of ultimate safety

-

Fire Exits are freely accessible

-

Flammable / Combustible materials are stored correctly with an inventory available

-

Information is easily accessible to the Fire Brigade

Electrical Hazards

-

Extensions cords are not used as permanent wiring

-

Plugs are in good condition

-

Sockets are in good condition

-

Electrical safety inspections are carried out?

Commercial Kitchens

-

Is there a commercial kitchen onsite?

-

Is "Better food Better Business" available?

-

Is the "Better food Better Business" diary in use?

-

Are daily temperature checks being carried out?

Hygiene of Food Room and Equipment

-

Are food rooms and equipment in good condition and well maintained?

-

Are food rooms clean and tidy and do staff clean as they go including difficult areas?

-

Is equipment easy to clean and kept in a clean condition?

-

Are all food and hand contact surfaces e.g. work surfaces, fridge handles, probe thermometers, in good condition and cleaned?

-

Is probe thermometer disinfected regularly?

-

Are suitable approved cleaning chemicals available and stored correctly and are proper cleaning methods used?

Food storage

-

Are deliveries appropriately stored immediately?

-

Is ready-to-eat food stored above/separate from raw food in the fridges and freezers?

-

Is food in fridges/freezers covered?

-

Is high risk food check for date & stock rotated (FIFO)?

-

Are high risk foods date coded?

-

Are dried goods stored correctly e.g. in a suitable room, off the floor, in covered containers?

-

Is outer packaging removed from ready-to-eat food before being placed into a clean area?

-

Are freezers working properly?

-

Are fridges and freezers defrosted regularly?

Food handling practices

-

Do staff's wash hands frequently while handling ready to eat food?

-

Are ready-to-eat foods prepared in separate clean areas?

-

Are separate utensils and equipment used for ready-to-eat foods ?

-

Is wrapping and packaging used for ready-to-eat food kept in the clean area?

-

Do separate staff handle ready-to-eat food or are controls being followed to ensure staff change clothing and wash hands before handling ready-to-eat food?

-

Is separate ***complex equipment provided for ready-to-eat food and is it located in the clean area?

-

Are staff handling food as little as possible? (e.g. using tongs)

-

If colour coded equipment is provided (e.g. utensils, chopping boards), is it correctly used?

-

Are high risk foods prepared in small batches and placed in the fridge immediately after handling/preparation?

-

Is food cooled as quickly as possible away from raw food and other sources of contamination?

-

Are vegetables/fruit/salads/ trimmed and washed thoroughly before use unless labelled as ‘ready-to-eat’?

-

Are frozen foods defrosted safely?

-

Are controls in place to prevent contamination by chemicals/foreign bodies e.g. glass, packaging materials, bolts, rust, cleaning chemicals?

-

Are staff aware of food allergy hazards?

-

Are controls being followed to ensure staff wash hands after handing raw food and before touching surfaces?

-

Is a separate probe thermometer used for ready-to-eat foods and properly cleaned/disinfected before use?

External Hazards

External Hazards

-

Is there systems in place to prevent unauthorised access?

-

Is the lighting sufficient externally throughout the site?

-

Please upload photos from around the site after dark

-

Is external lighting controlled by a timer?

-

Are all external surfaces in a good condition

-

Walkways are free from trip hazards

-

Man hole covers are easily accessible and are in good condition

-

All ramps are of a safe gradient and have sufficient friction

-

Are all stairwells in a good condition with sufficient handrails

-

Are there any fragile roofs onsite?

-

Are the warning signs clearly displayed warning of fragile roofs?

-

Please raise an action for signage to be displayed warning of fragile roof

-

Are there any areas of the site that are derelict or hidden away?

-

Is there a Ice & Snow plan for the site

-

Rubbish is stored away from the building?

-

Is there any concern with vermin onsite?

Trees

-

Are there any trees onsite?

-

When was the last tree survey undertaken?

-

Is there an active management plan for trees onsite to ensure they do not encroach on or cause risk to roads, paths and buildings?

Water

-

Are there any ponds?

-

Is there adequate protection to stop Children & Adults falling into them?

-

Are there any Swimming Pools?

-

The pool has measures to protect people from falling into the pool

-

The pool has proper signage

-

The pool has lifeguarding arrangements in place suitable to the use of the pool

-

There is access to summon emergency assistance to the pool

-

All chemicals are stored securly

-

The chemical balance of the pool is tested regularly and there is a written schedule

-

Stairs and ladders are in good condition

-

Water depths are clearly marked

-

Water system is protected against backflow

-

Water recirculation and filtration is adequate

Other Risks

-

To begin the workplace risk assessment, select the "+" icon next to Hazard:

Hazard

-

Description of hazard / concern

-

Photo of the hazard (optional)

-

How may the hazard be realised and what are the potential outcomes

-

Who or What might be harmed?

-

Risk likelihood

-

Risk consequences

-

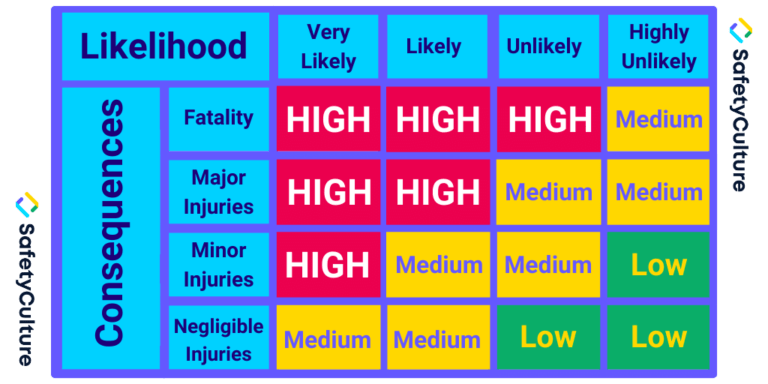

Use this risk matrix to identify the risk level:

-

Risk level

-

Hazard causing risk can be eliminated?

-

Are you already doing something to control this risk (existing risk control measure)?

-

Develop a risk control measure targeting this risk & add actions

-

What control measures are required

-

Briefly describe the existing control measure:

-

Further action needed to control the risk?

-

Select the "Action" icon to create an action, assign it to someone, and set a due date.

-

Eliminate the hazard causing the risk.

-

Are you already doing something to control this risk (existing risk control measure)?

-

Briefly describe the existing control measure:

-

Further action needed to control the risk?

-

Select the "Action" icon to create an action, assign it to someone, and set a due date.

-

Further action needed to control the risk?

-

Select the "Action" icon to create an action, assign it to someone, and set a due date.

-

Monitoring of this risk is in place?

-

Any additional comments

-

To ADD another hazard to the workplace risk assessment, select the "+" icon next to Hazard.

To END the workplace risk assessment, select the "Next Page >" button at the bottom right.

Other Hazards

-

Are pedestrians and vehicles separated?

-

Is there any Gas stored onsite?

Completion/Review

-

What risk control measures have you developed?

-

Has the hierarchy of controls been applied to all hazards effectively

-

Where PPE has been suggested as a control measure has the RA detailed the exact specification requirement

-

How will you monitor the effectiveness of these risk control measures?

-

How often will you review this workplace risk assessment?

- Every 2 weeks

- Every month

- Every 3 months

- Every 6 months

- Every year

- Every 15 months

-

The HSE recommends reviewing workplace risk assessments at least annually.

Responsible persons

-

Name of Responsible person

-

Role

-

Name Person completing the Risk Assessment

Guidance

-

This risk assessment has been undertaken to provide information to those responsible for the management of the site named. Attention is drawn to a number of key pieces of H&S legislation;

Health & Safety at work act etc. 1974 & its associated regulations

Management of HSW regulations

Legionella

Asbestos

COSHH

PPE

Occupiers Liability Acts

This list is not exhaustive and others may apply. -

Auditor biography