Title Page

-

Conducted on

-

Prepared by

-

Location

SITE SAFETY INSPECTION

Administrative

-

Daily JSA or AHA forms

-

Toolbox Meeting Records

-

First Aid Kit Stocked and up to date?

-

Map/Directions to Hospital Location

-

Medical Transportation Plan

Fall Protection Plan

-

Approved Fall Protection Plan

-

-

-

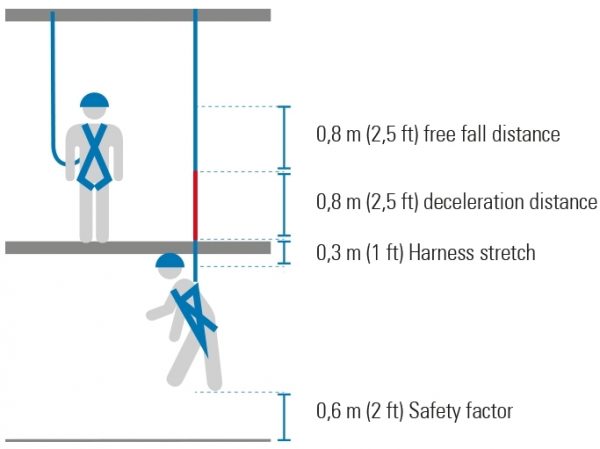

Fall clearance

-

Proper/Approved Anchorage Points- withstand 5k ibs or 220ibs worker with deceleration device withstand 1,8k ibs

-

Horizontal Lifelines

-

Guardrails-42"H+ 21"H midrail & withstand 200lbs of downward force<3"deflect

-

Warning Line 15' from Leading Edge capable of resisting, without tipping over, a force of at least 16 pounds applied horizontally against the stanchion, 30 inches above the walking/working surface

-

Open Holes Protected/Labeled/Guarded

-

Rescue Plan in Place and Reviewed

-

Rescuers/Equipment Onsite

-

OSHA

1926.1211(a)

An employer who designates rescue and emergency services, pursuant to § 1926.1204(i), must:

1926.1211(a)(1) Evaluate a prospective rescuer's ability to respond to a rescue summons in a timely manner, considering the hazard(s) identified;

Note to paragraph (a)(1). What will be considered timely will vary according to the specific hazards involved in each entry. For example, § 1926.103 (Respiratory protection) requires that employers provide a standby person or persons capable of immediate action to rescue employee(s) wearing respiratory protection while in work areas defined as IDLH atmospheres.

1926.1211(a)(2)

Evaluate a prospective rescue service's ability, in terms of proficiency with rescue-related tasks and equipment, to function appropriately while rescuing entrants from the particular permit space or types of permit spaces identified;

1926.1211(a)(3)

Select a rescue team or service from those evaluated that:

1926.1211(a)(3)(i)

Has the capability to reach the victim(s) within a time frame that is appropriate for the permit space hazard(s) identified;

1926.1211(a)(3)(ii)

Is equipped for, and proficient in, performing the needed rescue services;

1926.1211(a)(3)(iii)

Agrees to notify the employer immediately in the event that the rescue service becomes unavailable;

1926.1211(a)(4)

Inform each rescue team or service of the hazards they may confront when called on to perform rescue at the site; and

1926.1211(a)(5)

Provide the rescue team or service selected with access to all permit spaces from which rescue may be necessary so that the rescue team or service can develop appropriate rescue plans and practice rescue operations.

1926.1211(b)

An employer whose employees have been designated to provide permit space rescue and/or emergency services must take the following measures and provide all equipment and training at no cost to those employees:

1926.1211(b)(1)

Provide each affected employee with the personal protective equipment (PPE) needed to conduct permit space rescues safely and train each affected employee so the employee is proficient in the use of that PPE;

1926.1211(b)(2)

Train each affected employee to perform assigned rescue duties. The employer must ensure that such employees successfully complete the training required and establish proficiency as authorized entrants, as provided by §§ 1926.1207 and 1926.1208;

1926.1211(b)(3)

Train each affected employee in basic first aid and cardiopulmonary resuscitation (CPR). The employer must ensure that at least one member of the rescue team or service holding a current certification in basic first aid and CPR is available; and

1926.1211(b)(4)

Ensure that affected employees practice making permit space rescues before attempting an actual rescue, and at least once every 12 months, by means of simulated rescue operations in which they remove dummies, manikins, or actual persons from the actual permit spaces or from representative permit spaces, except practice rescue is not required where the affected employees properly performed a rescue operation during the last 12 months in the same permit space the authorized entrant will enter, or in a similar permit space. Representative permit spaces must, with respect to opening size, configuration, and accessibility, simulate the types of permit spaces from which rescue is to be performed.

1926.1211(c)

Non-entry rescue is required unless the retrieval equipment would increase the overall risk of entry or would not contribute to the rescue of the entrant. The employer must designate an entry rescue service whenever non-entry rescue is not selected. Whenever non-entry rescue is selected, the entry employer must ensure that retrieval systems or methods are used whenever an authorized entrant enters a permit space, and must confirm, prior to entry, that emergency assistance would be available in the event that non-entry rescue fails. Retrieval systems must meet the following requirements:

1926.1211(c)(1)

Each authorized entrant must use a chest or full body harness, with a retrieval line attached at the center of the entrant's back near shoulder level, above the entrant's head, or at another point which the employer can establish presents a profile small enough for the successful removal of the entrant. Wristlets or anklets may be used in lieu of the chest or full body harness if the employer can demonstrate that the use of a chest or full body harness is infeasible or creates a greater hazard and that the use of wristlets or anklets is the safest and most effective alternative.

1926.1211(c)(2)

The other end of the retrieval line must be attached to a mechanical device or fixed point outside the permit space in such a manner that rescue can begin as soon as the rescuer becomes aware that rescue is necessary. A mechanical device must be available to retrieve personnel from vertical type permit spaces more than 5 feet (1.52 meters) deep.

1926.1211(c)(3)

Equipment that is unsuitable for retrieval must not be used, including, but not limited to, retrieval lines that have a reasonable probability of becoming entangled with the retrieval lines used by other authorized entrants, or retrieval lines that will not work due to the internal configuration of the permit space.

1926.1211(d)

If an injured entrant is exposed to a substance for which a Safety Data Sheet (SDS) or other similar written information is required to be kept at the worksite, that SDS or written information must be made available to the medical facility treating the exposed entrant. -

Evaluate a prospective rescue service's ability, in terms of proficiency with rescue-related tasks and equipment, to function appropriately while rescuing entrants from the particular permit space or types of permit spaces identified; select a rescue team or service from those evaluated that:

Has the capability to reach the victim(s) within a time frame that is appropriate for the permit space hazard(s) identified; Is equipped for, and proficient in, performing the needed rescue services.

Aerial Lifts

-

Qualified Operator

-

Daily Inspection

-

User Manual

-

Rescue Plan in Place and Reviewed

-

Warning Labels

-

Firm and Level Surface

-

Fall Protection

Ladders

-

Correct Type for the Task

-

Inspected Prior to Each Use

-

3 Points of Contact

-

Extend 3' Above Landing (Extension)

-

Secured or Spotter Utilized

-

Fully Open and Locked (A-frame)

Falling Objects

-

Drop Zone

-

Tool Lanyards

-

Safety Net

-

Toe Boards

-

Open Holes Protected

PPE

-

Hard Hat

-

Safety Glasses

-

Safety Boots

-

Full Length Pants

-

Gloves (Proper for Task)

-

Hearing Protection

-

High Visibility Clothing

-

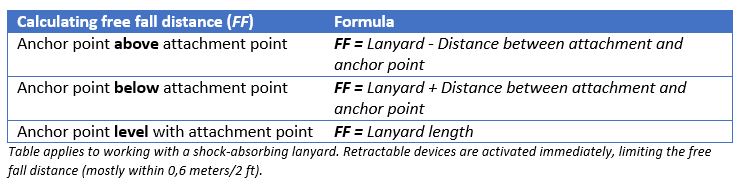

Arc Flash Clothing

-

Face Shield

-

Respiratory Protection

HazCom

-

SDS List Updated

-

SDS's Onsite and Updated

-

Chemicals Labeled

-

Proper Storage

-

HazCom Training

Scaffolding

-

Competent Person

-

Daily Inspection

-

Access Ladders

-

Guardrails

-

Planking

-

Proper Footing and Base

Hazardous Energy Control

-

Approved HECP in Place

-

LOTO DEVICES

-

Equipment De-energized

Electrical

-

Qualified Electrical Person-possess verifiable credentials

-

Arc Flash Protection Boundry Established

-

-

Arc Flash PPE available and inspected

-

Check for potentially energized electrical equipment

-

Inspect Rubber Gloves Check Dates

-

Live Circuits Protected

-

Cords/Power Tools

-

Asured Grounding/GFCI's

-

Flame Resisant Clothing

-

Inspect Electrical Safety Equipment-PPE, faceshield, sle

Powerlines

-

Safe Limits of Approach

-

Spotter with Airhorn

-

Operating Voltage Known

-

Appropriate Signage

Traffic Control

-

Approved Traffic Control Plan

-

Message Boards

-

Traffic Control Devices and signage

-

Certified Flagperson

-

Adequate Stop/Slow paddles

Gas Cylinders

-

Container Labeling

-

Valve Caps in Place

-

Fuel Gas Separation

-

Stored Upright / Secured

-

Signage

Abrasive Blasting

-

Daily Inspection

-

Warning Signs

-

Dust Control

-

Connections Secured

-

Audible Alarm

-

Blasting Medium SDS

Fire Protection/Prevention

-

Fire Extinguishers (Placement, Insp.)

-

Fire Extinguisher shall be provided for each 3,000 sq. ft. of the protected building area.

-

Travel distance from any point of the protected area to the nearest fire extinguisher shall not exceed a 100 feet.

-

At least one fire extinguisher provide on each floor.

-

In multistory buildings, at least one fire extinguish shall be located adjacent to stairway.

-

In accordance with NFPA 10A-12018 for monthly inpection?

-

Hot Work Permit Completed

-

Flammables Removed (Hot Work)

-

Fuel (Storage Tanks/Safety Cans)

-

Safety Systems (Sprinklers)

-

Fire Watch

Sanitation

-

Potable Water

-

Adequate and Portable Toilet Facilities

Mobile Hoisting Equipment

-

Daily Inspection

-

Competent Operator

-

Competent Spotter

-

Competent Rigger/Signaller

-

Load Radius Chart

-

Lift Plan Onsite and Reviewed

Mobile Equipment

-

Qualified Operator

-

Backup Alarm

-

Fire Extinguisher

-

Rollover Protection

Excavations

-

Competent Person

-

Daily/Periodic Inspection

-

All Utilities Identified (Above/Below)

-

Water in Trench

-

Proper Access/Egress

-

Atmosphere Tested/Documented

-

Warning/Barricade System

-

Signage

Confined Space

-

Approved Confined Space Entry Plan

-

Confined Space Permit Complete

-

Competent Person

-

Atmospheric Monitor

-

Attendant

-

Communication

-

Onsite Evac and Rescue

-

Rescue Equipment

-

Rescue Plan Reviewed

Environmental

-

Housekeeping

-

Wetlands

-

Haz Waste Disposal

Observations

-

Correction Actions

-

Contractor Representative Signature

-

Site Safety and Health Officer Signature