Title Page

-

Job Number

-

Inspection Date

-

Inspected by

-

Address

-

Was the insured or home occupier on site at the time of the site safety inspection?

-

Were trades onsite at the time of the inspection?

Induction & Safety Talks

-

If the worker does not have a copy of the WWC certificate of completion available these can be searched via WOLF / Trade Contacts / Documentation

-

Have workers completed White Wolf Constructions online safety induction?

- Sighted worker's WWC certificate of completion

- Not all workers have completed WWC's online safety induction

-

Do workers have their white cards available for inspection?

- Sighted workers white cards

- Not all workers had their white cards available

-

Is there evidence of written pre-start talks, take 5's or toolbox talks?

- Sighted copies of pre-start, toolbox or take 5 talks,

- There is no evidence of per-start or toolbox talks being conducted

-

Discuss this with the trade supervisor and highlight his WHS obligation regarding consultation

Emergency Preparedness

-

Is a First aid kit avaliable to workers?

- A First Aid kit was onsite at the time of the inspection

- There was not a First Aid kit onsite at the time of the inspection

-

Is the First Aid kit fully stocked?

- The First Aid kit appeared to be fully stocked

- The First Aid kit lacked supplies

-

Was any hot works being conducted at the time of the inspections? (Sparks or naked flame)

- Hot Works were being performed at the time of the inspection

- No Hot Works were being performed at the time of the inspection

-

Was a portable fire extinguisher available within the hot work zone?

- A portable fire extinguisher was sighted at the hot work zone

- A portable fire extinguisher was not available at the hot work zone

Housekeping

-

Is rubbish placed in skip bins or designated stockpiles?

- All rubbish is placed in skip bins, stockpiled or removed from site daily

- The majority of rubbish is placed in bins or stockpiled, however the site requires a general clean

- Delivered materials have been placed on the nature strip

- Delivered materials have been placed on the front grass/garden

- The site requires an urgent clean

-

Is there clear access around the site? (No trip hazards, pathways are clear)

- There is clear access around the site

- Pathways are blocked with building materials

- Pathways are blocked with demolition debris

-

Are building materials stacked/stored in a manner to prevent overbalancing?

- Building materials are stacked/stored in an orderly manner

- Building materials are unorganised and requires stacking

- There are no excess building materials onsite

Work at Heights

-

Does this job involve any work at heights where there is the risk of a person falling more than 2 metres?

-

How is fall protection being managed?

- Scaffold

- Perimeter Roof Safety Rail

- PPE - Harness

- Fall protection is no in place

-

Has the Perimeter Roof Safety Rail handover certificate been uploaded to the WOLF job card?

- The handover certificate has been uploaded to the WOLF job card

- The handover certificate has not been uploaded to the WOLF job card

-

Discuss this with the Estimator/Supervisor responsible for the job

-

Does the Perimeter Roof Rail has an access gate? Reference AS 4994.1 Clause 3.4.2 (f) "The design of the roof edge protection shall take into account the safety of persons passing through the roof edge protection to gain access to the roof."

- Access to the roof complies with AS 4994.1

- Access to the roof does not comply with AS 4994.1

-

AS 4494.1 Clause 3.4.2

-

Is the roof rail intact or does it appear to be tampered with or components are missing?

- Viewed from the ground the roof rail appears to be intact

- Viewed from the ground the roof rail system appears to been tampered with or components are missing

-

If the roof rail appears to have been tampered with, issue a stop work instruction and discuss corrective actions with site workers. A toolbox talk should also be held to discuss tampering with roof rail components and general falls from height.

-

Is the scaffold complete or being erected?

-

Is there signage displayed indicating "Scaffold Incomplete Do Not Use"?

- Signage is displayed indicting the scaffold is incomplete

- Signage is not displayed indicating the scaffold is not to be used

-

Is the scaffold 4 metres or greater in height to the working platform?

-

Has the Scaffold handover certificate been uploaded to the WOLF job card?

- The scaffold handover certificate has been uploaded to the WOLF job card

- The scaffold handover certificate has not been uploaded to the WOLF job card

-

Discuss this with the Estimator/Supervisor responsible for the job

-

Has the scaffold been inspected and tagged within the 30 day inspection cycle?

- The scaffold inspection is within the 30 day cycle

- The scaffold is overdue for an inspection

- A scaffold tag could not be located

-

Are any scaffold components missing? e.g. handrail, toe board, planks etc

- A visual inspection indicates the scaffold is intact and has not been tampered with

- A visual inspection indicates the scaffold has been tampered with

-

If the scaffold appears to have been tampered with issue a stop work instruction and discuss corrective actions with site workers. A toolbox talk should also be held to discuss the implications of unauthorised removal of scaffold components and general falls from height.

-

Are there excessive building materials stacked on the scaffold? (consider weight or loose materials that could be dislodged by wind)

- The scaffold is free of excess building materials or debris

- There is excess building materials or debris on the scaffold

-

Do all safety harnesses have an AS 1891 tag visible?

- AS 1891 tag identified on safety harness

- AS 1891 tag not visible on safety harness

-

If the safety harness does not have an AS 1891 tag it cannot be used

-

Have safety harnesses been inspected and tagged within the mandatory 6 month cycle?

- The current inspection tag is within the regulation 6 month period

- The safety harness is overdue for an inspection

-

A safety harness that has not been inspected within the 6 month range cannot be used

-

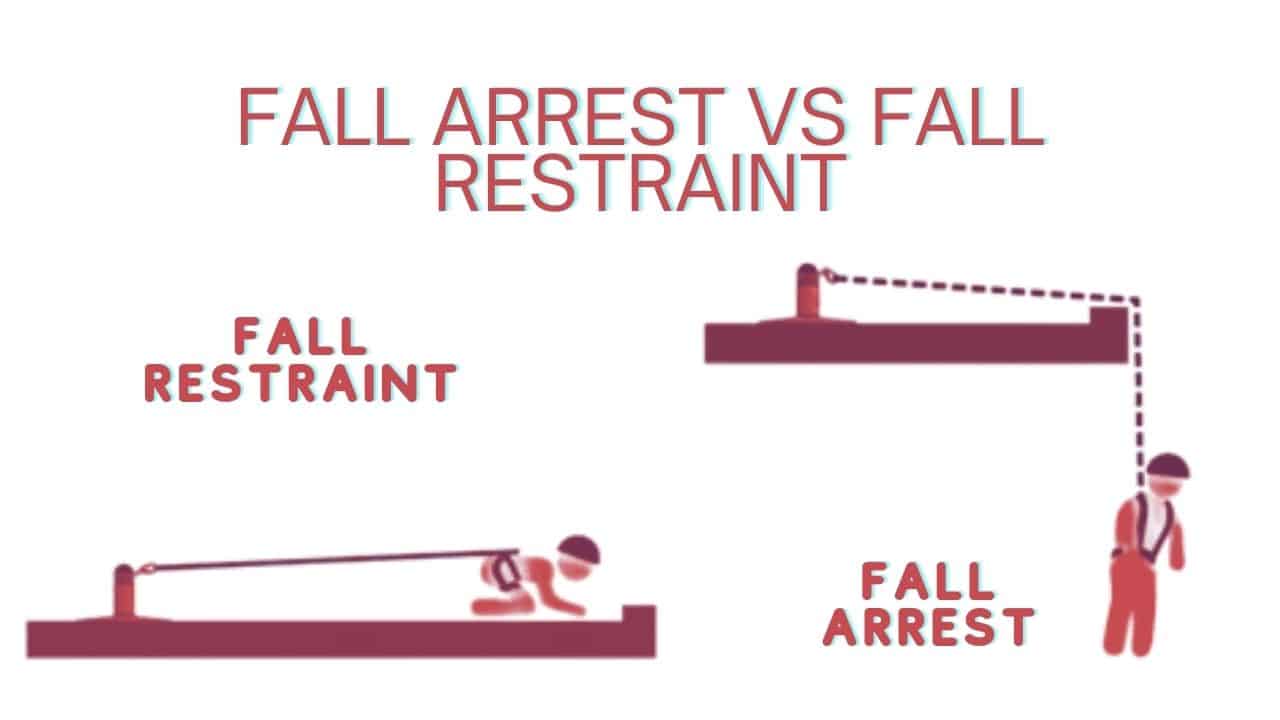

Is the safety harness configured to "fall restraint"?

- The safety harness was configured on 'fall restraint'

- The safety harness was configured in 'fall arrest'

- The safety harness was not secured to a point of attachment

-

Issue stop work instruction and discuss Work at Height Safety with workers. Work can not proceed until the safety harness is reconfigured to Fall Restraint. A toolbox talk should be conducted to record the discussion.

-

Is there a written Work at Heights Rescue procedure available as per WHS Regulations Section 80?

-

https://legislation.nsw.gov.au/view/html/inforce/current/sl-2017-0404#sec.80

Portable Ladders

-

-

-

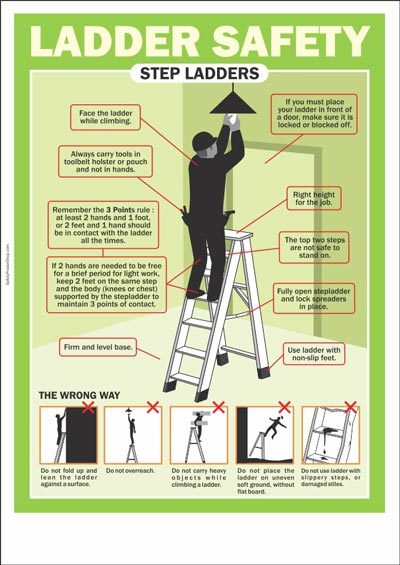

Are step ladders onsite use during the inspection?

-

Are step ladders rated at a minimum 120kg?

- Ladders are rated at a minimum 120kg

- Ladders are rated below 120kg

- The manufacturers label cannot be read or is missing

-

Are step ladders in good condition? ( No missing or non-manufacturer parts)

- Ladders are in good condition

- Faulty ladder - missing component

- Faulty ladder - non manufacturer component fitted

- Faulty ladder - damaged or bent arm or step

-

Are any step ladders less than 1200mm in height?

- All step ladders were are a minimum 1200mm at the time of the inspection

- Step ladders less than 1200mm were identified onsite at the time of the inspection

-

Are there any step ladders labelled "Domestic" onsite?

- There were no domestic labelled ladders identified onsite at the time of the inspection

- A domestic labelled ladder was identified onsite at the time of the inspection

-

Are step ladders being used as a work platform? i.e. Used to support planks

- Step ladders were being used as a stand alone device

- It was observed that step ladders were being used as a work platform to elevate and support workers

- There were no trades onsite at the time of the inspection

-

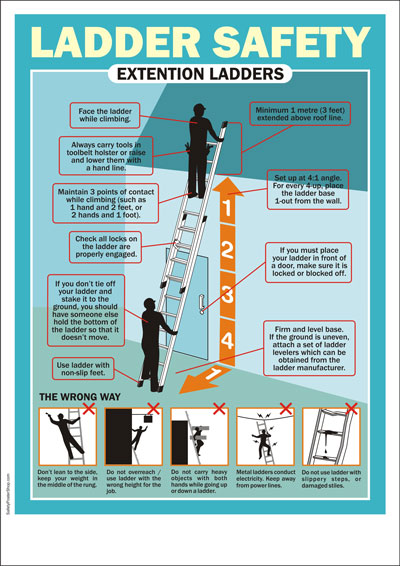

Are extension ladders in use at the time of the inspection?

-

Is the extension ladder secured at the top and or bottom to prevent slipping?

- The extension ladder was secured to prevent slipping at the time of the inspection

- The extension ladder is not secured to prevent slipping at the time of the inspection

-

Does the extension ladder protrude at least 1 metre above the top of the access point?

- Extension ladder protruded 1 metre past the access point at the time of the inspection

- Extension ladder did not protrude 1 metre past the access point at the time of the inspection

-

Is the extension ladder positioned at a ratio of 4:1?

- The extension ladder was positioned at the correct ratio of 4:1

- The extension ladder was not positioned at the correct ratio of 4:1

-

Does the extension ladder have a minimum 120kg rating?

- Ladders are rated at a minimum 120kg

- Ladders are rated below 120kg

- The manufacturers label cannot be read or is missing

Electrical

-

Were electric power tools and or equipment being used at the time of the inspection?

-

Are power tools and or equipment tested and tagged at a maximum 3 month intervals?

- A random sample of power tools & equipment indicates testing and tagging occurs within the prescribed range

- A random sample of power tools indicates testing and tagging does not occur with the prescribed range

- A faulty power appliance was identified during the inspection

-

Are portable RCD boxes in use?

- Sighted RCD in use

- RCD's are not used. Sighted power tools plugged directly into wall sockets.

-

WHS approved RCD Box

-

Note : It is mandatory that subcontractors electrical equipment is plugged into a portable RCD and not house power outlets.

-

Are extension leads elevated or positioned as not to create a trip hazard or suffer from damage due to mechanical impact

- Extension leads were elevated or positioned in a manner not to create a trip hazard or suffer from damage due to mechanical impact at the time of the inspection

- Extension leads were observed to create trip hazards or could be damaged from mechanical impact at the time of the inspection

- N/A Cordless tools in use at time of inspection

- No extension leads in use at the time of inspection

-

Do power tools have manufacturer guarding/protective devices fitted?

- Power tools have manufacturers guarding/protection fitted at the time of the inspection

- Power tools have had the manufacturers guarding/protection removed

-

Power tools that are missing manufacturer fitted guards must be removed from site (typically grinders)

General Safety

-

Where required, are safety or warning signs clearly displayed?

- Safety /warning signs were displayed at the time of the inspection

- Safety/warning signs are not required for the works being conducted at the time of the inspection

- Safety/warning signs are required

-

Are there any building elements that could cause impalement or puncture wounds?

- Elements that posed a risk of impalement or puncture were protected

- There was a risk of impalement or puncture wound at the time of the inspection

- No building elements or material posed a risk to impalement or puncture wounds at the time of the inspection

-

Are pressurised cylinders (oxy or gas bottles) unrestrained?

- Pressurised cylinders were restrained at the time of the inspection

- There were no pressurised cylinders onsite at the time of the inspection

- Pressurized cylinders were observed unrestrained at the time of the inspection

-

Is there sufficient natural or artificial lighting to safely complete work tasks?

- There was sufficient natural or artificial lighting at the time of the inspection

- Task lighting is required

- N/A - There were no subcontractors onsite at the time of the inspection

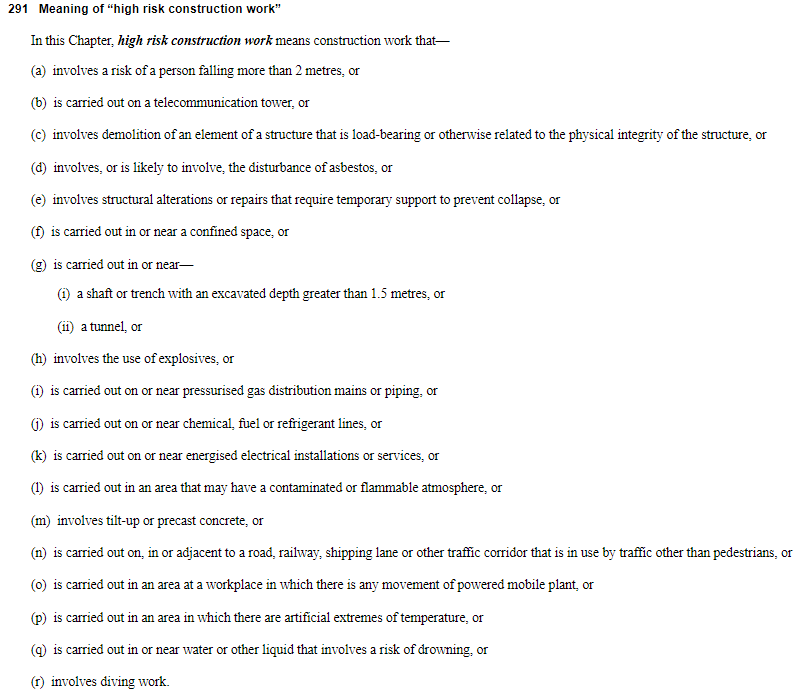

High Risk Construction Work

WHS Regulations - Clause 291

-

-

Was any High Risk Construction Work (as per WHS Regulations) being conducted at the time of the inspection?

- High Risk Construction Work was being performed at the time of the inspection

- High Risk Construction Work was not being performed at the time of the inspection

-

Was there a Safe Work Method Statement onsite describing the control measures for the High Risk Construction Work?

-

Has the SWMS been signed by workers performing the High Risk Construction Work?

- SWMS was signed by workers

- SWMS has not been signed by workers

Additional Optional Items

-

Positive Observations

-

Room for Improvement

-

General

-

Submit Report

-

As there are no trades onsite at the time of the inspection a number of safety inspection categories have been disabled from this audit

Housekeeping

-

Is rubbish placed in skip bins or designated stockpiles?

- All rubbish is placed in skip bins, stockpiled or removed from site daily

- The majority of rubbish is placed in bins or stockpiled, however the site requires a general clean

- Delivered materials have been placed on the nature strip

- Delivered materials have been placed on the front grass/garden

- The site requires an urgent clean

-

Is there clear access around the site? (No trip hazards, pathways are clear)

- There is clear access around the site

- Pathways are blocked with building materials

- Pathways are blocked with demolition debris

-

Are building materials stacked/stored in a manner to prevent overbalancing?

- Building materials are stacked/stored in an orderly manner

- Building materials are unorganised and requires stacking

- There are no excess building materials onsite

Work at Heights

-

At the time of the site inspection was a scaffold or perimeter roof safety rail installed for future use?

-

Please select the type of fall protection installed.

- Scaffold

- Perimeter Roof Rail

-

Is the scaffold complete or still being erected?

-

Is there signage indicating "Incomplete Scaffold Do No Use"?

- Signage is clearly displayed indicating the scaffold is incomplete

- There is no signage displayed to indicate the scaffold is incomplete

-

Has the scaffold handover certificate been uploaded to the WOLF job attachments?

- Yes, Handover certificate has been uploaded to WOLF

- No, Handover certificate has not been uploaded to WOLF

-

Discuss this with the Estimator/Supervisor responsible for the job and Trade Manager

-

Has the scaffold been inspected and tagged at the maximum 30 day periods?

- The current scaffold tag is within the latest 30 day period

- The scaffold is overdue for an inspection

-

Are any scaffold components missing? e.g. handrail, toe board, planks etc

- A visual inspection indicates the scaffold is intact and has not tampered with

- A visual inspection indicates the scaffold has been tampered with

-

Are there excessive building materials stacked on the scaffold? (consider weight or loose materials that could be dislodged by wind)

- The scaffold is free of excess building materials or debris

- There is excess building materials or debris on the scaffold

-

Has the Perimeter Roof Rail handover certificate been uploaded to the WOLF job attachments?

- Yes, Handover certificate has been uploaded to WOLF

- No, Handover certificate has not been uploaded to WOLF

-

Discuss this with the Estimator/Supervisor responsible for the job and Trade Manager

-

Does it appear roof rail components have been tampered with or are missing?

- Viewed from the ground, the roof rail systems appears intact

- Viewed from the ground, the roof rail system appears to have been tampered with.

Additional Items

-

Additional unsafe items identified during the site safety inspection. (Please provide details and photos)

-

Comments by the insured or home occupier regarding quality, timeliness etc. (Optional)

-

Submit Report