Title Page

-

Conducted on

-

Prepared by

-

Location

-

Tasks

-

Team Members

1. High Risk Activities

High Risk Work Activities

-

1.1 High risk work activities

- Risk of fall greater than 2 metres

- Demolition of a load bearing structure

- Disturbance of asbestos

- Using temporary support to prevent collapse

- Confined space

- In / near shaft, tunnel or trench deeper than 1.5m

- On or near pressurized gas mains or piping

- On or near chemical, fuel or refrigerant lines

- On or near energised electrical installation

- Contaminated or flammable atmosphere

- On, in or adjacent to traffic corridor

- Movement of powered mobile plant

- Artificial extremes of temperature

- In or near liquid where there is a risk of drowning

- This work does not involve any high risk activities

-

Do you have a SWMS / risk assessment that covers the risk of fall greater than 2m?

-

By checking this box, I am confirming that I have completed a SWMS / risk assessment for the risk of fall greater than 2m and if required I have added actions or notes to this question.

-

Do you have a SWMS / risk assessment that covers the demolition of a load bearing structure?

-

By checking this box, I am confirming that I have completed a SWMS / risk assessment that covers the demolition of a load bearing structure and if required I have added actions or notes to this question.

-

Do you have a SWMS / risk assessment that covers the disturbance of asbestos?

-

By checking this box, I am confirming that I have completed a SWMS / risk assessment that covers the disturbance of asbestos and if required I have added actions or notes to this question.

-

Do you have a SWMS / risk assessment that covers the safe use of temporary support to prevent collapse?

-

By checking this box, I am confirming that I have completed a SWMS / risk assessment the safe use of temporary support to prevent collapse and if required I have added actions or notes to this question.

-

Do you have a SWMS / risk assessment for the confined space?

-

By checking this box, I am confirming that I have completed a SWMS / risk assessment for the confined space and if required I have added actions or notes to this question.

-

Do you have a SWMS / risk assessment for working in or near a shaft, tunnel or trench deeper than 1.5m?

-

By checking this box, I am confirming that I have completed a SWMS / risk assessment for working in or near a shaft, tunnel or trench deeper than 1.5m and if required I have added actions or notes to this question.

-

Do you have a SWMS / risk assessment for working on or near pressurized gas mains or piping?

-

By checking this box, I am confirming that I have completed a SWMS / risk assessment for working on or near pressurized gas mains or piping and if required I have added actions or notes to this question.

-

Do you have a SWMS / risk assessment for working on or near chemicals, fuel or refrigerant lines?

-

By checking this box, I am confirming that I have completed a SWMS / risk assessment for working on or near chemicals, fuel or refrigerant lines and if required I have added actions or notes to this question.

-

Do you have a SWMS / risk assessment for working on or near the energised electrical installation?

-

By checking this box, I am confirming that I have completed a SWMS / risk assessment for working on or near the energised electrical installation and if required I have added actions or notes to this question.

-

Do you have a SWMS / risk assessment for working in a contaminated or flammable atmosphere?

-

By checking this box, I am confirming that I have completed a SWMS / risk assessment for working in a contaminated or flammable atmosphere and if required I have added actions or notes to this question.

-

Do you have a SWMS / risk assessment for working on, in or adjacent to the traffic corridor?

-

By checking this box, I am confirming that I have completed a SWMS / risk assessment for working on, in or adjacent to the traffic corridor and if required I have added actions or notes to this question.

-

Do you have a SWMS / risk assessment for working in the vicinity of powered mobile plant?

-

By checking this box, I am confirming that I have completed a SWMS / risk assessment for working in the vicinity of powered mobile plant and if required I have added actions or notes to this question.

-

Do you have a SWMS / risk assessment for working in the artificial extremes of temperature?

-

By checking this box, I am confirming that I have completed a SWMS / risk assessment for working in the artificial extremes of temperature and if required I have added actions or notes to this question.

-

Do you have a SWMS / risk assessment for working in or near liquid where there is a risk of drowning?

-

By checking this box, I am confirming that I have completed a SWMS / risk assessment for working in or near liquid, where there is a risk of drowning, and if required I have added actions or notes to this question.

-

Move onto section 2

2. Stop and Think

Stop and Think

-

2.1 Do I understand what I need to do?

-

DO NOT START WORK. By checking this box you are confirming that you have notified your JCU Rep / Manager and you now understand what you need to do.

-

2.2 Do I have all the permit I require?

-

DO NOT START WORK. By checking this box, you are confirming that you have contacted the JCU Rep / Manager and you now have all of the correct permits in place.

-

2.3 Are the right people / tools / equipment / PPE available?

-

DO NOT START WORK source equipment/tools/PPE or review the risk assessment to determine alternative controls. By checking this box I am confirming that the right tools / equipment / PPE are available.

-

2.4 Is there a SWP / guideline / SWMS / risk assessment?

-

DO NOT START WORK. By checking this box I am confirming that I have a SWP / guideline / SWMS / risk assessment applicable to the work.

-

2.5 Can I conduct the work in accordance with the SWP / guideline / SWMS / risk assessment?

-

DO NOT START WORK. By checking this box I am confirming that I can follow all controls in the SWP / guideline / SWMS / risk assessment or I have reassessed the risks and controls and recorded these changes.

-

2.6 Have I communicated with other workers any hazards that may affect me or them?

-

DO NOT START WORK. By checking this box I am confirming that I have now communicated hazards to all workers who may be affected by them.

-

2.7 Am I trained / qualified and competent to do this work?

-

DO NOT START WORK source equipment/tools/PPE or review the risk assessment to determine alternative controls. By checking this box I am confirming that the right tools / equipment / PPE are available.

-

2.8 Is supervision (if required) available?

-

DO NOT START WORK until the correct supervision is in place. By checking this box I am confirming that supervision is appropriate for the work.

-

2.9 Will others nearby be safe during my work?

-

DO NOT START WORK. By checking this box I am confirming that I have reassess my work practices and all controls will now ensure others nearby will be safe during my work.

-

2.10 Do I understand what to do in an emergency?

-

DO NOT START WORK. By checking this box I am confirming that I have contacted the JCU Rep / Manager and I now understand what to do in an emergency.

-

2.11 Have I done everything possible to minimise the risk?

-

DO NOT START WORK. By checking this box I am confirming that everything possible has now been taken to minimise the risk.

-

2.12 Am I fit to do the work (i.e. free from fatigue, alcohol / drugs, medical illness, etc.)?

-

WORKERS WHO ARE UNFIT TO DO THE WORK MUST NOT START WORK. By checking this box I am confirming that I am now fit to do the work.

-

2.13 Is it safe to complete this task in the current weather / environmental conditions?

-

DO NOT START WORK. By checking this box you are confirming that the weather/environmental conditions are now suitable to conduct the work or controls have been implemented to allow part/all of the activities to continue (add controls to the action / notes for this question).

-

2.14 Are all hazards controlled?

-

DO NOT START WORK. By checking this box you are confirming that all hazards are now controlled.

3. Hazards and Controls

-

Select the hazards that apply to this work.

- Manual tasks (lifting, awkward or over exertion)

- Gravity (slips, trips, falls, falling objects)

- Radiation (UV, x-ray)

- Electricity (faulty tools, live power)

- High Pressure (gas, air, liquid)

- Working alone

- Biological (infectious diseases, zoonosis)

- Machinery and equipment (caught in, on or between, struck by plant, flying objects)

- Heat / cold

- Chemical

- Noise

- Hot works

-

Manual tasks hazard controls

- Mechanical devices (trolley, forklift)

- 2 person lift

- Split load into smaller containers

-

Gravity hazard controls

- Barricading

- Fall prevention

- Fall restraint

- Spotter

- Lanyards

- Bench / batter / shore

- Structural supports in place

- Ladder safe work procedure

- SWMS greater than 2m risk of fall

- Permit - Working at heights

- Permit - Excavations

-

Radiation hazard controls

- Isolation

- Work planned around high UV times

- Shade identified

- PPE

- Radiation specific induction

-

Electrical hazard controls

- SWMS (energised work)

- Permit - LV isolation / HV Exclusion Zone

- Inspection

- Lock out / tag out

- Test and tag

- RCD (residual current device)

-

High pressure hazard controls

- Isolation of energy sources

- Location of hazards

-

Working alone controls

- Communication person identified and available

- Emergency response planned

-

Biological hazard controls

- Immunisations

- PPE (gloves, masks, eye protection)

- Decontamination certificate received (sighted)

- Laboratory induction / escort

-

Machinery and equipment hazard controls

- Guarding

- Barricading

- Signage

- Lock out / tag out

- Interlocks

- PPE

- Traffic Management

- SWMS (powered mobile plant / working on roads)

- Permit - Traffic corridor

- Permit - Fire protection system isolation

- Permit - Energy isolation

-

Chemical hazard controls

- SDS available

- Ventilation appropriate

- Using chemical in accordance with the manufacturers directions

- PPE

- SWMS (chemical, fuel, refrigerant lines / disturb asbestos)

- Permit - Asbestos

-

Heat / cold hazard controls

- SWMS (artificial extreme temperatures)

- Check safety devices (e.g. alarms, locks)

- Communication equipment

- PPE

-

Noise hazard controls

- Isolate the area

- Hearing protection

-

Hot work hazard controls

- Permit - Hot works

-

Additional hazards and controls

4. Is it SAFE to start work?

Is it safe to start work?

-

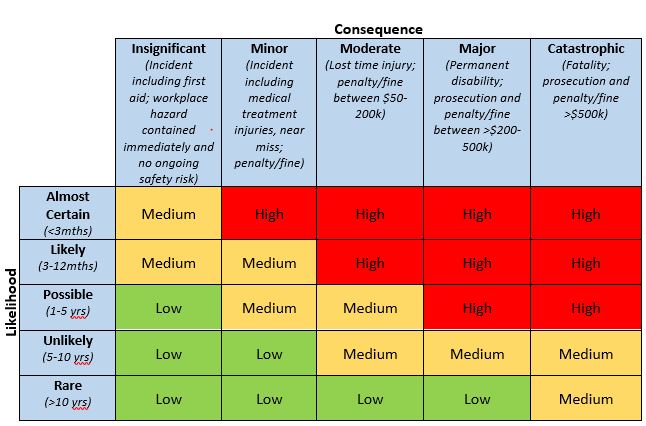

JCU Risk Matrix

-

Using the JCU risk matrix, the overall risk level for this work with controls in place (current risk level) is?

-

Acceptable Level of Risk, START WORK

-

By checking this box you are confirming that all reasonably practicable controls are being used and the JCU Rep / Manager has agreed that this level of risk is acceptable. START WORK.

-

DO NOT START WORK. The current level of risk is unacceptable. If the level of risk can not be reduced to medium or low, contact the JCU Rep / Manager for further direction.