Title Page

-

Site name/address

-

Document No.

-

Principal Contractor/Client

-

Completed on

-

Form completed by

-

Location

-

TDE workers on site

Information

-

Principal / Client

-

TDE Site Foreman

-

Description of work to be completed today

-

Take a photo of the work site - include as much as you can

General Checks

GENERAL CHECKS

-

Has the site hazard board been reviewed and updated as required? Take a photo if you can.

-

If there is a hazard board, ensure this is done before work starts.

-

Have all workers been inducted to the site? <br>E.g. Site induction completed by principal contractor, or induction by you for workers/visitors in your work area

-

Ensure this is done before work starts.

-

Are there other contractors working very nearby, or in the same area as you today?

-

Have you communicated with other contractors to make sure risks that may affect one another are known, understood and effectively managed?

-

Under the law, you must have consulted, co-operated and co-ordinated your activities with other contractors to ensure risks to health and safety are eliminated or minimised. Do this before you start work.

-

A current and complete first aid kit, charged fire extinguisher are readily available

-

You must resolve this ASAP. No work posing a risk of fire may be conducted until an extinguisher is available.

-

A fully stocked spill kit is readily available

-

If your work involved hazardous liquids (including those in mobile plant), a spill kit should be available to contain and clean up any spills. Please advise the office.

-

A first-aider is readily available?

-

A trained first-aider should be readily available at all times. Check if nearby contractors have one. Advise the office of training requirements.

-

Are there any inspections, quality checks or tests required today?

-

Please book any inspections now if not done so already. Ensure all testing equipment is available as required. Inform all workers.

-

Have you discussed any important items with workers? E.g. Issues which need to be discussed / resolved, critical control measures, hold points etc.

-

Describe the issues/discussion. How will issue be resolved, by when, and who is responsible?

Equipment and PPE Checks

EQUIPMENT AND PPE CHECKS

-

In addition to hi-viz and safety boots, the PPE required today is (select all that apply)

- Hard hat

- Hearing protection

- Safety glasses

- Safety goggles

- Heavy duty gloves

- Chemical resistant gloves

- Tripod and harness

- Disposable mask

- Half face respirator

- Disposable coveralls

- Full face shield

- Full face respirator

- Boot covers or slip on boots only (asbestos work)

- Other (add to notes)

-

Is all required PPE available and in good condition?

-

You must have the proper PPE, in good condition, before commencing work, or reschedule the task.

-

Equipment required today is (select all that apply)

- Air pressure test equipment

- Compactor

- Compressor

- Crane

- Excavator/s and attachments

- Gas detector

- Hand tools

- H2O Truck / Trailer

- Power tools (saws, grinders concrete breaker etc.)

- Truck/s

- Water pressure test equipment

- Wheelbarrow

- No equipment is required today

- Other (add to comments)

-

Is all required equipment available and fit for purpose / suitable for the task?

-

You must ensure equipment is available and fit for purpose before commencing work

-

Is all equipment in good condition, and has current inspections, certifications, warrants, maintenance records etc. as required?

-

Any equipment which is not up to standard must be removed from service immediately and clearly labelled as such. Advise the office.

Hazard Identification & Risk Management

HAZARD IDENTIFICATION AND RISK MANAGEMENT

-

Are you excavating near underground services?

-

Do you have service plans?

-

Have services been located? E.g. by hydrovac, radar and mark out etc.?

-

Which critical risks do you expect to encounter today?

- Airborne contaminants

- Asbestos

- Confined or restricted space work

- Contaminated soil

- Electrical equipment

- Hazardous products

- Load lifting / rigging

- Mobile plant

- Open excavations / trenches

- Overhead services, e.g. powerlines

- Power tools

- Quick hitches

- Traffic

- Trailers, loads and tip trucks

- Underground services

-

Do all risks identified in the Job H&S Plan have effective, standard controls implemented?

-

Which risks do not have standard controls implemented, and why not? Describe what controls you have implemented to minimise the risk so far as reasonably practicable?

-

Use the below hazard identification tool to identify any other hazards that may be present. Think about the most critical risks.

-

Are there any other critical risk hazards specific to the work site today, that have not been identified in your Job H&S Plan, or that are unable to be controlled in the normal way? <br>HINT: Especially think about anything not routinely encountered and anything specific to the job or site today.

-

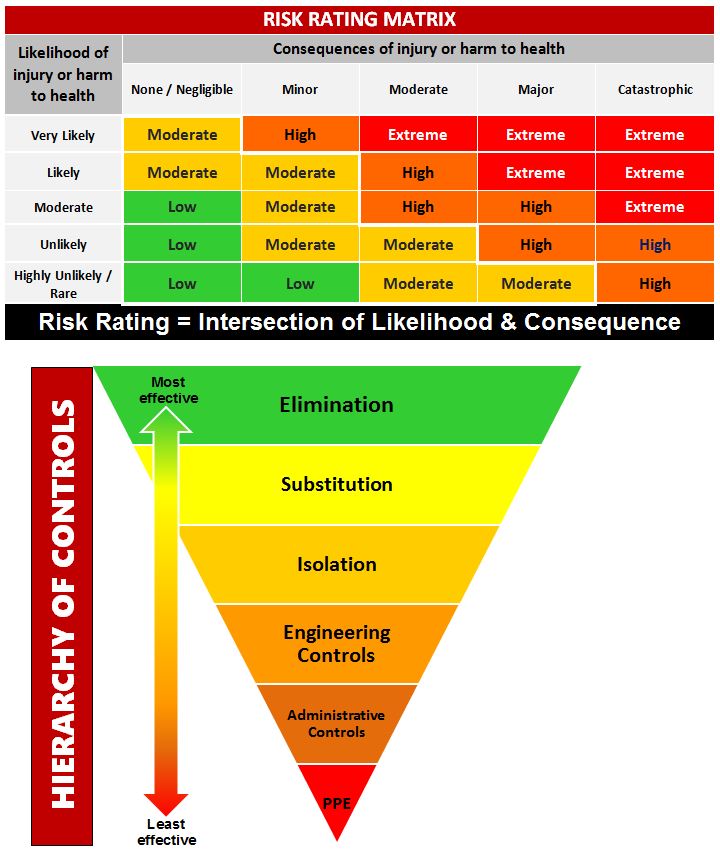

Use the below risk rating matrix and hierarchy of controls tools to select the most effective controls and ensure the risk is reduced to an acceptable level (moderate or less)

-

Add each hazard

Hazard

-

Describe the hazard / risk (What could cause harm and how?)

-

Describe the controls (How will you reduce the likelihood or consequence f harm?)

-

What is the risk rating for this hazard, with controls implemented? (Use the matrix)

-

STOP! That risk to too high. Re-think your controls as they are not effective enough. Once you have determined controls, re-assess the risk. You cannot proceed with work with a risk rating of High or Extreme. Call the office if you need help.

Sign Off

SIGN OFF

-

The foreman and ALL TDE workers must be involved in completing the daily plan and must sign below to indicate they have understood the information.

Other visitors to the work area must be informed of the information contained in this daily plan, as relevant to their visit, and must sign below to indicate they have understood the information. -

Foreman sign off

-

Worker Sign Off

Worker

-

Worker Sign Off

-

Other Visitor Sign Off

Other Visitor

-

Other Visitor Sign Off