Information

-

Document No.

-

Audit Title

-

Client / Site

-

Conducted on

-

Location

-

Assessor

-

Trainee

-

BOST Group Tracked Jaw Crusher Competency

-

Person being assessed:

-

Assessors Name

- Jason MacDonald

- Darrell Porter

- Jeff Binder

-

Only a qualified, experienced supervisor from the list can perform this competency test.

Pre-shift Planning

-

Is this person competent at;

-

Clarifying work location, task and work instructions?<br>Traffic management plan ?<br>Restricted Areas

-

Ensuring that any required permits are completed / obtained ?

-

Identifying environmental hazards in the work area including;<br>Inclement weather<br>Dust<br>Fog<br>Poor Lighting / Reduced Visibility<br>

-

Identifying other site hazards;<br>Powerlines<br>Underground services including power, gas, sewer, water<br>Trenches, Soft ground<br>Unexploded Ordinance<br>Benches<br>Dial before you Dig

-

Ensuring that correct refuelling and daily maintenance procedures are followed ?

-

Wearing and fitting all the necessary PPE ? <br>Hard hat, boots, safety glasses / goggles, hearing protection, gloves, isolation padlock, high visibility long sleeve clothing

-

Identifying the correct emergency response procedures ?<br>Channel 11, Emergency, Emergency, Emergency <br>State the nature of the incident<br>Location<br>Resources required<br>Do not attempt help if too dangerous

-

Finding MSDS / SDS (safety data sheets) and understanding their contents ?

Pre-Start Inspection

-

Locating, identifying and using supplied spill kits if necessary ?

-

Complete and document a daily Pre-Start Inspection on an approved BOST Group Pre-Start Checklist Sheet.

-

Is this person competent at checking from ground level:

-

All Danger Tags, tools or rags have been removed from the machine ?

-

Condition of access ladders, walkways and platforms?

-

Condition of handrails?

-

Condition of emergency stops and labels?

-

Condition of fire extinguisher?

-

Condition of hydraulic hoses and telescopic rams?

-

Level of grease pot and condition of lines if autogrease module is fitted ?

-

Identifying the location of all nip points on machine ?

-

Identifying the location of all grease points on machine ?

-

Identifying the feed bin ?

-

Identifying the vibrating feeder / apron feeder ?

-

Identifying the main conveyor ?

-

Identifying the jaw crusher ?

-

Identifying the magnet belt (if fitted) ?

-

Identifying the tracks and chassis ?

-

Identifying the power train ?

-

Chassis, conveyor frame and bin for cracks and/or damage?

-

Condition of tracks, assemblies and track tension ?

-

Checking drive couplings for wear or misalignment ?

-

Condition of Feeder bin structure and vibrating / apron feeder ?

-

Condition of jaw liners and cheek plates ?

-

Condition of conveyor belting and skirting rubber ?

-

Condition of belts scrapers and plows ?

-

Condition of guards. Are they all fitted ?

-

Head and Tail Drum bearings ?

-

Condition of chutes ?

-

Is this person competent at:

-

Checking radiator level? (Only when engine is cold) and if a radiator is fitted.

-

Checking engine oil level?

-

Checking hydraulic oil level?

-

Checking fuel level?

-

Checking air cleaner(s)?

-

Checking battery & battery leads?

-

Checking engine for leaks?

-

Checking fan and alternator belts?

-

Checking radiator hoses and clamps?

-

Assessor Signature

-

This person is competent at performing a pre-start on this jaw crusher.

Start Up:

-

After Pre-Start, the jaw crusher is ready to start up.

-

Is this person competent at:

-

Checking that the area around jaw crusher is clear before startup ?

-

Starting the engine without revving?

-

Allowing the engine to idle for approximately 2-5 minutes to warm up.

-

Is this person competent at checking the following whilst engine is warming up

-

Lights

-

Gauges

-

Oil or fluid leaks ?

-

Checking for First Aid Kit ?

-

The jaw crusher is now ready for work.

Tramming / Walking Jaw Crusher

-

Is this person competent at performing the following once the engine has warmed up

-

Adjusting engine speed from idle to full speed to move onsite and adjusting from full speed back to idle for tramming into or out of workshop and onto or off a float ?

-

Engaging track mode by selecting switch or moving levers ?

-

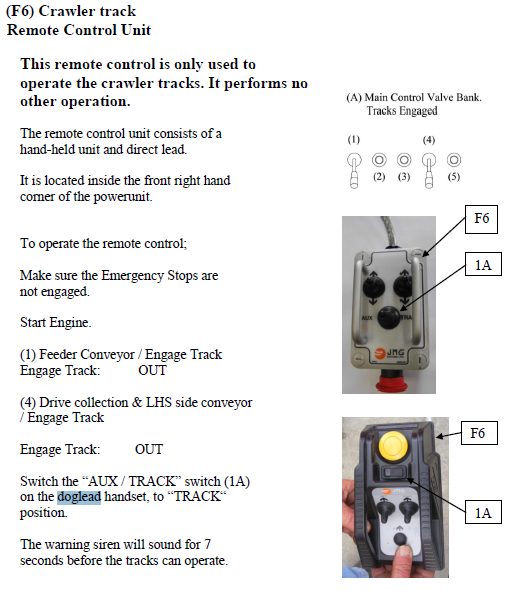

Locating the umbilical / doglead remote handset and ensuring that it is correctly attached ?

-

Maximus Dogleads

-

Portafill Dogleads - Old Style

-

Portafill Dogleads - New Style

-

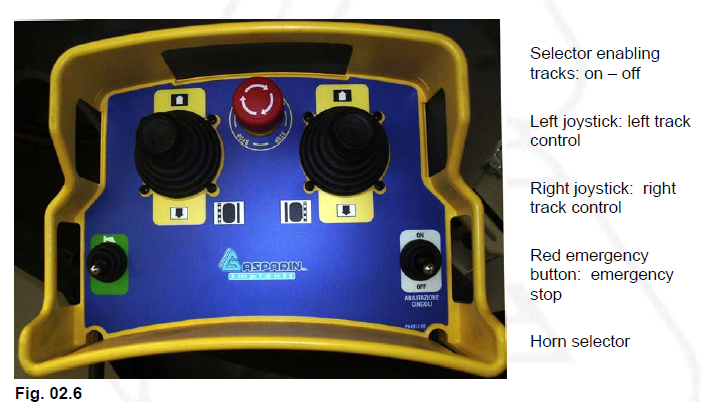

Gasparin Dogleads

-

Rotating the handset so that the steering controls are correctly aligned with the walking direction of the plant ?

-

Ensuring that a competent, authorised spotter is available before moving the screen and that hand signals are agreed upon ?

-

Ensuring the path of travel is clear of obstructions and people ?

-

Ensuring that first gear forward or reverse is selected ?

-

All guards, conveyors and jack legs are raised ?

-

Conveyor belting is laid down in the machine travel path when entering and exiting the workshop or any other concreted area ?

Operating Jaw Crusher

-

Is this person competent at performing the following once the engine has warmed up

-

Adjusting engine speed from idle to full speed ?

-

Operating tail drum raising and lowering before and after tracking machine ?

-

Turning on magnet belt (if fitted) ?

-

Turning on scalping belt (if fitted) ?

-

Making sure main conveyor is running before starting jaw ?

-

Turning on jaw crusher before starting feeder ?

-

Turning on vibrating feeder / apron conveyor ?

-

Checking that all the Belts and rollers are all turning freely ?

-

Checking that all the belts are tracking correctly ?

-

Checking that all the pressures and settings are correct ?

-

Adjusting the jaw CSS setting to suit the application and feed source material ?

SAFETY AROUND CRUSHING AND SCREENING PLANT

-

A HARD HAT and all appropriate PPE MUST BE WORN WHILST WORKING

NEAR ANY OF BOST GROUPS CRUSHING AND SCREENING PLANT -

Assessor Signature

-

This person has been proven competent in the operations of the jaw crusher.

Shut Down:

-

Is this person competent at:

-

Allowing the jaw to completely clear all product from the system ?

-

Stopping the vibrating feeder / apron feeder first ?

-

Stopping the jaw next ?

-

Stopping the main conveyor last ?

-

Allowing the engine to idle for 2-5 minutes before turning off?

-

Completing walk around the machine to check for any damage or repairs needed?

-

Completing walk around the machine to check for any spillage points ?

-

Turning off battery isolator ?

-

Assessor Signature

-

This person has been proven competent in the shut down of the jaw crusher ?

Competency

-

All competency outcomes achieved?

-

Assessor Comments

-

This person can positively identify the main components, perform pre-start checks, start, operate and shut down the jaw crusher.

-

Supervisor/Assessor Signature

-

Trainee Signature