Title Page

-

FDH Number

-

IM Ticket Number

-

Cabinet Serving Area

- Hamilton West

- Hamilton East

- Tauranga West

- Tauranga East

- Te Awamutu

- Cambridge

- Tokoroa

- New Plymouth

- Wanganui

- Hawera

-

Conducted on

-

Prepared by

-

Location

-

Personnel

- Pre maintenance Survey

Distribution Patch Panel (DPP) door (Before Photos)

-

Take a photo of the front of the OCP (Feeder)

-

Take a photo of the top third of the front of the DPP.

-

Take a photo of the middle third of the front of the DPP.

-

Take a photo of the bottom third of the front of the DPP.

-

Open DPP door and remove the pigtail protection cover.

-

Take a photo of of the rear of the OCP (Feeder)

-

Take a photo of the top third of the rear of the DPP.

-

Take a photo of the middle third of the rear of the DPP.

-

Take a photo of the bottom of the rear of the DPP.

-

Does the cabinet have a functioning door retention clip.

-

Photograph the DPP Door Retention Clip.

-

Any additional information and observations

-

Take a photo of issues observed that has not already been recorded.

Trays (Before Photos)

-

Take photos of all ABF trays (particular attention to broken or faulty trays)

-

Take photos of the feeder trays (particular attention to broken or faulty trays)

-

Take photos of the ADSS (particular attention to broken or faulty trays)

-

Any additional information and observations

-

Take a photo of issues observed that has not already been recorded.

Micro Duct Gland plate (Berofe Photos)

-

(From left to right) Take a photo of the first third of the Micro Duct Gland Plate.

-

Take a photo of the middle third of the Micro Duct Gland Plates

-

Take a photo of the remaining Micro Duct Gland Plates.

-

Any additional information and observations

-

Take a photo of issues observed that has not already been recorded.

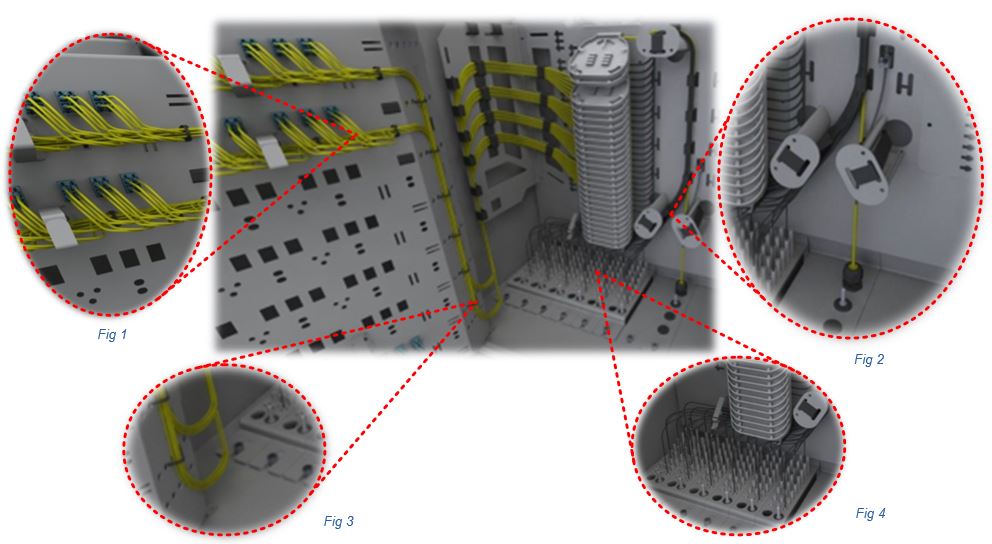

Pigtail and Distribution Cable Route.

-

-

Take photo of the pigtail and cable route replicating the picture above.

-

Take a photo of issues observed that has not already been recorded.

-

Add media

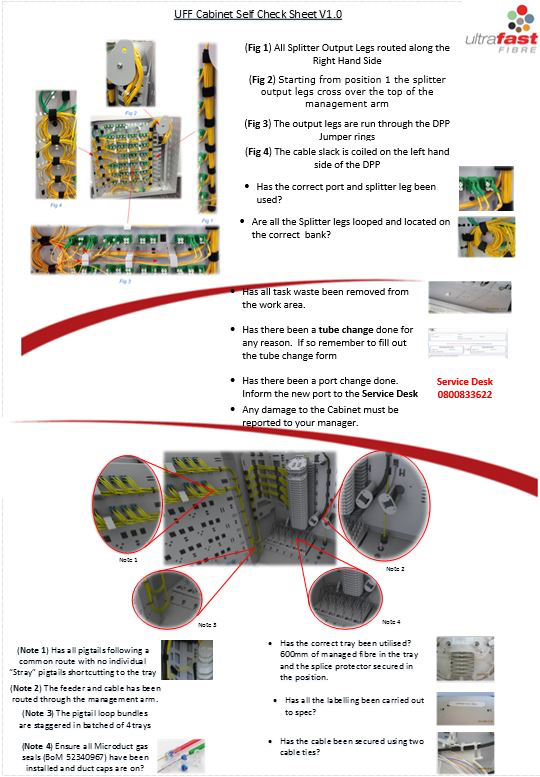

Post Maintenance Activities Record.

Cabinet Interior

-

Ceiling insulating foam re-attached.

-

Brief description of why the task cannot be completed.

-

Take photo of the cabinet roof.

-

Any additional information and observations

-

Take photo of issues observed that has not already been recorded.

Cabinet exterior

-

Is there any signs of graffiti.

-

Take photo of the cabinet exterior to record the graffiti.

-

Is there any vegetation encroachment into the cabinet working area.

-

Take photo of the cabinet surroundings to capture any vegetation or graffiti.

-

Any additional information and observations

-

Take a photo of issues observed that has not already been recorded.

Cabinet Door

-

-

Attach the UFF Cabinet self check sheet V1.0 onto the cabinet door.

-

Brief description of why the task cannot be completed.

-

Replace Locking mechanism.

-

Brief discription on why the task cannot be completed.

-

-

Take a photo of the inside if the cabinet door replicating the photograph above. ( post maintenance activities)

-

Any additional information and observations

-

Take a photo of issues observed that has not already been recorded.

DPP Door

-

Additional Cable Management Hooks installed.

-

Brief description of why the task cannot be completed.

-

Additional Optical Adaptors ( Bulkheads) installed

-

Brief description of why the task cannot be completed

-

All dust caps fitted into the Bulkheads.

-

Splitter Output legs restored and conform with Technical Update 020 and the SDU installation standards

-

Take photo of the front of the DPP if not already captured.

-

Brief description of why the task cannot be completed.

-

Door retention clip been replaced.

-

Brief description of why the task cannot be completed.

-

Main compartment is clean, free from dirt and moisture and all task waste removed.

-

Take a photo of the DPP Door if not already captured above. (Post maintenance activities)

-

Take a photo of the rear of the DPP (Post maintenance activities)

-

Take a photo of the front of the DPP (post Maintenance activities)

-

Any additional information and observations

-

Take a photo of issues observed that has not already been recorded.

Duct Maintenance

-

All ducts have the appropiate gas seals.

-

Brief description of why the task cannot be completed.

-

Install an end cap on all micro ducts

-

Cut down the 14/10mm tubes.

-

Brief description of why the task cannot be completed.

-

All kinked need fibre repaired.

-

Brief description of why the task cannot be completed.

-

All ABF ducts have Duct caps.

-

Brief description of why the task cannot be completed.

-

100mm ducts are sealed and to standard.

-

Photo of the gland plates.(post maintenance activities)

-

Any additional information and observations

-

Take a photo of issues observed that has not already been recorded.

Labelling.

-

All labelling conforms to UFF ODN labelling and Network Naming Convention.

-

Brief description of why the task cannot be completed.

-

Labelling upgraded to encompass Technical Update 047 Splice Tray labelling.

-

Brief description of why the task cannot be completed.

-

Multiple photographs of the labelling ( post maintenance activities)

-

Any additional information and observations

-

Take a photo of issues observed that has not already been recorded.

Plinth maintenance

-

Re-terminate locate wires to the isolated earth stubb.

-

Brief description of why the task cannot be completed.

-

Check connection to the isolated earth stubb.

-

Photograph the underside of the gland plate.( post maintenance activities)

-

Photograph the earth stake. ( post maintenance activities)

-

Any additional information and observations

-

Take a photo of issues observed that has not already been recorded.

FDH Surround

-

Surrounding area of FDH is free from Defects (BRS Vans driving on grass verges)

Task activies and coded rates

-

The following tasks are identified for bundling into the regular cabinet maintenance routine and are associated code is UFFM44

- Hinge replacement (Provided by UFF)

- Door replacement (Provided by UFF)

- Lock mechanism replacement if broken (provided by UFF)

- Graffiti (where easy)

- Vegetation (as per B&M Agreement)

- Task Waste Management ongoing

- Check functional earth stake connection and refasten if required

- Ceiling foam check in place and refasten if required

- UFF cabinet self-check sheet V1.0 in place on door (supplied by UFF)

- FDH patch door support clip replaced where broken on an ongoing basis.

- Check locate wire and re-terminate if required

- FDH ID Labels are visible and to Standard

- Air Vents are clear obstacles

- Check concrete plinth for structural integrity

- Rust and paintwork (excluding Graffiti)

- Rodent/insect infestation

- Install Fibre warning sticker -

Were the tasks and activities conducted for code UFFM44 and code UFFM44 claimed

-

Take photos of the work carried out

-

Tray replacement is associated to Code UFFM45

-

Were the tasks and activities conducted for code UFFM45 and code UFFM45 claimed

-

How many trays were replaced.

-

Take photos of the completed work

-

Labelling to meet with UFF Technical Update 047 (FDH Splice Tray Labelling) is associated to code UFFM46.

-

Were the tasks and activities conducted for code UFFM46 and code UFFM46 claimed

-

Take photos of the completed work.

-

The following bundle tasks are identified and the associated with code UFFM47

- Cut-down 14/10 tube – Technical update 045 (1min task – one off)

- New FDH patch door support clip installed – Technical update 044 (5min task – one off)

- Splitter port status – record those not yet used, in Te Awamutu only. (UFF FDS staff to complete similar FDH checks in other areas).

- Install fibre management hooks (If not already installed as per provisioning)

- Install bulk heads on patch panels (If not already installed as per provisioning) -

Were the tasks and activities conducted for code UFFM47 and code UFFM47 claimed

-

Please take photos of the completed work.

-

Any additional information and observations

-

Take a photo of issues observed that has not already been recorded.

Sign Off

-

UFF Contractor Sign Off