Information

Before starting any new document ensure to refer to previous visits/interactions to identify any outstanding actions that may need to be carried forward. Any progress should be recognised and praised.

-

Engineer details (**payroll number must be included**)

-

Prepared by

-

Conducted on

-

Visit Type

- HomeSafe

- RTW

- Post Check

- Damage Claim

- Investigation

- Coaching

- Equipment Inspection

- 121

- IDD

- Probation Discussion

TM RISK ASSESSMENT

TM RISK ASSESSMENT

-

Are there any hazards?

-

Hazard type

- Traffic

- Ground

- Third Party

- Weather

-

Are hazards controllable?

-

Details

-

Visit type

- HomeSafe

- RTW

- Post Check

- Damage Claim

- Investigation

- Coaching

- Equipment Inspection

- 121

- IDD

- Probation Discussion

HOMESAFE

-

Job No

-

Job type

- Service

- Install

- Install (multi-screen)

- MHO

- MHO (multi-screen)

- Other

-

Observation

-

Is the Engineer working safely on arrival?

-

Risk Assessment

-

WHAT? (what was Safe/ Unsafe?)

-

WHY? (why did the Engineer do it this way?)

-

HOW? (how was this recognised/ refined/ rectified?)

-

Manual Handling

-

WHAT? (what was Safe/ Unsafe?)

-

WHY? (why did the Engineer do it this way?)

-

HOW? (how was this recognised/ refined/ rectified?)

-

PPE

-

WHAT? (what was Safe/ Unsafe?)

-

WHY? (why did the Engineer do it this way?)

-

HOW? (how was this recognised/ refined/ rectified?)

-

Damage Awareness

-

WHAT? (what was Safe/ Unsafe?)

-

WHY? (why did the Engineer do it this way?)

-

HOW? (how was this recognised/ refined/ rectified?)

-

Working at Height

-

WHAT? (what was Safe/ Unsafe?)

-

WHY? (why did the Engineer do it this way?)

-

HOW? (how was this recognised/ refined/ rectified?)

-

Ladder type

- No Ladder

- Step/ Combi

- Single Section

- Double Section

- Triple Section

- CAT

- DAT

- SAT (inc rope access)

- Access Ladder (inc flat roof working)

- 10 Rung

- Rope Assisted 15 Rung

- Rope Assisted 19 Rung

-

How was Combi- ladder used?

-

Additional record of findings (Equipment set up and description of job as was carried out. Highlight positive aspects of work witnessed)

-

Add pictures to support observation (inc RAMS forms if applicable)

-

Additional HomeSafe on this visit

-

Job No

-

Job type

- Service

- Install

- Install (multi-screen)

- MHO

- MHO (multi-screen)

- Other

-

Risk Assessment

-

WHAT? (what was Safe/ Unsafe?)

-

WHY? (why did the Engineer do it this way?)

-

HOW? (how was this recognised/ refined/ rectified?)

-

Manual Handling

-

WHAT? (what was Safe/ Unsafe?)

-

WHY? (why did the Engineer do it this way?)

-

HOW? (how was this recognised/ refined/ rectified?)

-

PPE

-

WHAT? (what was Safe/ Unsafe?)

-

WHY? (why did the Engineer do it this way?)

-

HOW? (how was this recognised/ refined/ rectified?)

-

Damage Awareness

-

WHAT? (what was Safe/ Unsafe?)

-

WHY? (why did the Engineer do it this way?)

-

HOW? (how was this recognised/ refined/ rectified?)

-

Working at Height

-

WHAT? (what was Safe/ Unsafe?)

-

WHY? (why did the Engineer do it this way?)

-

HOW? (how was this recognised/ refined/ rectified?)

-

Ladder type

- No Ladder

- Step/ Combi

- Single Section

- Double Section

- Triple Section

- CAT

- DAT

- SAT (inc rope access)

- Access Ladder (inc flat roof working)

- 10 Rung

- Rope Assisted 15 Rung

- Rope Assisted 19 Rung

-

How was Combi- ladder used?

-

Additional record of findings (Equipment set up and description of job as was carried out. Highlight positive aspects of work witnessed)

-

Add pictures to support observation (inc RAMS forms if applicable)

-

Additional HomeSafe on this visit

-

Job No

-

Job type

- Service

- Install

- Install (multi-screen)

- MHO

- MHO (multi-screen)

- Other

-

Risk Assessment

-

WHAT? (what was Safe/ Unsafe?)

-

WHY? (why did the Engineer do it this way?)

-

HOW? (how was this recognised/ refined/ rectified?)

-

Manual Handling

-

WHAT? (what was Safe/ Unsafe?)

-

WHY? (why did the Engineer do it this way?)

-

HOW? (how was this recognised/ refined/ rectified?)

-

PPE

-

WHAT? (what was Safe/ Unsafe?)

-

WHY? (why did the Engineer do it this way?)

-

HOW? (how was this recognised/ refined/ rectified?)

-

Damage Awareness

-

WHAT? (what was Safe/ Unsafe?)

-

WHY? (why did the Engineer do it this way?)

-

HOW? (how was this recognised/ refined/ rectified?)

-

Working at Height

-

WHAT? (what was Safe/ Unsafe?)

-

WHY? (why did the Engineer do it this way?)

-

HOW? (how was this recognised/ refined/ rectified?)

-

Ladder type

- No Ladder

- Step/ Combi

- Single Section

- Double Section

- Triple Section

- CAT

- DAT

- SAT (inc rope access)

- Access Ladder (inc flat roof working)

- 10 Rung

- Rope Assisted 15 Rung

- Rope Assisted 19 Rung

-

How was Combi- ladder used?

-

Additional record of findings (Equipment set up and description of job as was carried out. Highlight positive aspects of work witnessed)

-

Add pictures to support observation (inc RAMS forms if applicable)

-

Additional HomeSafe on this visit

-

Job No

-

Job type

- Service

- Install

- Install (multi-screen)

- MHO

- MHO (multi-screen)

- Other

-

Risk Assessment

-

WHAT? (what was Safe/ Unsafe?)

-

WHY? (why did the Engineer do it this way?)

-

HOW? (how was this recognised/ refined/ rectified?)

-

Manual Handling

-

WHAT? (what was Safe/ Unsafe?)

-

WHY? (why did the Engineer do it this way?)

-

HOW? (how was this recognised/ refined/ rectified?)

-

PPE

-

WHAT? (what was Safe/ Unsafe?)

-

WHY? (why did the Engineer do it this way?)

-

HOW? (how was this recognised/ refined/ rectified?)

-

Damage Awareness

-

WHAT? (what was Safe/ Unsafe?)

-

WHY? (why did the Engineer do it this way?)

-

HOW? (how was this recognised/ refined/ rectified?)

-

Working at Height

-

WHAT? (what was Safe/ Unsafe?)

-

WHY? (why did the Engineer do it this way?)

-

HOW? (how was this recognised/ refined/ rectified?)

-

Ladder type

- No Ladder

- Step/ Combi

- Single Section

- Double Section

- Triple Section

- CAT

- DAT

- SAT (inc rope access)

- Access Ladder (inc flat roof working)

- 10 Rung

- Rope Assisted 15 Rung

- Rope Assisted 19 Rung

-

How was Combi- ladder used?

-

Additional record of findings (Equipment set up and description of job as was carried out. Highlight positive aspects of work witnessed)

-

Add pictures to support observation (inc RAMS forms if applicable)

-

Additional HomeSafe on this visit

-

Job No

-

Job type

- Service

- Install

- Install (multi-screen)

- MHO

- MHO (multi-screen)

- Other

-

Risk Assessment

-

WHAT? (what was Safe/ Unsafe?)

-

WHY? (why did the Engineer do it this way?)

-

HOW? (how was this recognised/ refined/ rectified?)

-

Manual Handling

-

WHAT? (what was Safe/ Unsafe?)

-

WHY? (why did the Engineer do it this way?)

-

HOW? (how was this recognised/ refined/ rectified?)

-

PPE

-

WHAT? (what was Safe/ Unsafe?)

-

WHY? (why did the Engineer do it this way?)

-

HOW? (how was this recognised/ refined/ rectified?)

-

Damage Awareness

-

WHAT? (what was Safe/ Unsafe?)

-

WHY? (why did the Engineer do it this way?)

-

HOW? (how was this recognised/ refined/ rectified?)

-

Working at Height

-

WHAT? (what was Safe/ Unsafe?)

-

WHY? (why did the Engineer do it this way?)

-

HOW? (how was this recognised/ refined/ rectified?)

-

Ladder type

- No Ladder

- Step/ Combi

- Single Section

- Double Section

- Triple Section

- CAT

- DAT

- SAT (inc rope access)

- Access Ladder (inc flat roof working)

- 10 Rung

- Rope Assisted 15 Rung

- Rope Assisted 19 Rung

-

How was Combi- ladder used?

-

Additional record of findings (Equipment set up and description of job as was carried out. Highlight positive aspects of work witnessed)

-

Add pictures to support observation (inc RAMS forms if applicable)

Please ensure to upload a copy of this HomeSafe document to the relevant team folder on the designated Office365 site.

RTW

-

Type of absence

-

First day of absence

-

Last day of absence

-

Absence reason

- Alcohol/ Drug addition

- Allergy

- Asthma (excl work related)

- Blood disorder

- Breast problems

- Cancer/ Tumors

- Chest/ Respiratory problems

- Cold/ Cough/ Flu/ Influenza

- Dental

- Diabetes/ Thyroid/ Endocrine

- Disease of nervous system

- Ear/ Nose/ Throat condition

- Epilepsy or Neurological

- Eye problem

- Gastrointestinal problems

- Gynae including period pains

- Headache/ Migraine

- Heart/ BP/ Cirulatory

- Infectious disease

- Kidney/ Bladder problem

- Non work Injury/ Burn/ Fracture/ RTA

- Non work Musculoskeletal problem

- Non work Back/ Disc problem

- Occupational Asthma

- Occupational Dermatitis

- Pregnancy related

- Scheduall Sickness code

- Stess/ Anxiety/ Depression (non work)

- Stess/ Anxiety/ Depression (work related)

- Swine flu

- Unknown cause

- Vertigo/ Dizziness/ Insomnia

- Virus

- Work Injury/ Burn/ Fracture/ RTA

- Work related Musculoskeletal problem

- Work related Back/ Disc problem

- Other

-

Please state reasons

-

Is the absence work related?

-

Details

-

Was this a linked absence?

-

Details

-

Did Engineer visit a GP during their absence?

-

Is this absence over 7 days?

-

In line with the company absence policy if the absence is over 7 days the employee must provide a 'Fit to Work' certificate in order for a full return to work.

-

Has a 'Fit to Work' note been provided?

-

Add any pictures of 'Fit To Work' certificates

-

Is this absence over 7 days?

-

In line with the company absence policy if the absence is over 7 days the employee must provide a 'Fit to Work' certificate in order for a full return to work.

-

Is the Engineer currently on any medication?

-

Details of medication

-

Number of absences in rolling 12 months?

- 0 (first absence)

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10+

-

How many?

-

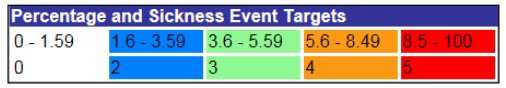

Percentage absence in rolling 12 months?

-

Has this absence triggered further action?

-

Process Triggered?

-

Absence Ref Guide

-

Occupational Heath referral required?

-

Date of referral/ planned referral

-

Additional information

-

If the returning Engineer has been off 28 days or more please refer to the RTWL in the first instance before a full return to work

-

Reason for Absence

-

Any follow up considerations?

-

Add any pictures of doctors notes

Please ensure to email a copy of this document to: admin.laserfiche@bskyb.com

Reopen Visit Type and include 'IDD' if required

POST CHECK

-

Job No

-

Date of Visit

-

Product Type

-

Job Type

- Service

- Install

- Install (multi-screen)

- MHO

- MHO (multi-screen)

- Other

-

Reason for Post Check

H&S

-

Is there evidence of H&S?

-

Do you have the Engineer's Risk Assessment for this job?

-

Is the Risk Assessment an accurate representation of work carried out?

-

Record of Findings

-

Add pictures to support findings

-

Record of Findings

-

Add pictures to support findings

QUALITY & COMPLIANCE

-

In YOUR opinion, has the work been carried out to a high standard?

-

F-Connectors

-

Power lead

-

HDMI lead

-

Dish

-

Cable

-

Is the Q on the correct software? <br>(Use iKnow2 Model Look Up Tool)

-

Add picture of screen to show software

-

Is the remote control paired to TV?

-

Is the picture resolution optimised?

-

Is the Q box connected to the internet?

-

Does the customer have the correct router?

-

Check the mesh and using Chrome and add picture

-

Has the engineer left the property tidy?

-

Record of Findings

-

Additional pictures to support findings

CUSTOMER

-

Having a conversation with the customer highlight any areas that were covered.

- ETA

- Engineer Appearance

- Engineer Attitude

- On Demand

- Demonstration / Showcase

- Sky Apps

- Pre / Post Job Walkthrough

-

Record any findings to support conversation

-

Add media

-

Customer Statement (Tick to add statement)

-

Engineer Rating - What rating would the customer give the visit?

- 0 - 😡

- 1 - 😡

- 2 - 😡

- 3 - ☹️

- 4 - ☹️

- 5 - ☹️

- 6 - ☹️

- 7 - 😕

- 8 - 😕

- 9 - 😀

- 10 - 😀

-

Job Type

- Service

- Install

- Install (multi-screen)

- MHO

- MHO (multi-screen)

- Other

-

Reason for Post Check

H&S

-

Is there evidence of H&S?

-

Do you have the Engineer's Risk Assessment for this job?

-

Is the Risk Assessment an accurate representation of work carried out?

-

Record of Findings

-

Add pictures to support findings

-

Record of Findings

-

Add pictures to support findings

QUALITY

-

In YOUR opinion, has the work been carried out to a high standard?

-

Record of Findings

-

Has the engineer left the property tidy?

-

Add pictures to support findings

CUSTOMER

-

Having a conversation with the customer highlight any areas that were covered.

- ETA

- Engineer Appearance

- Engineer Attitude

- On Demand

- Demonstration / Showcase

- Sky Apps

- Pre / Post Job Walkthrough

-

Record any findings to support conversation

-

Customer Statement (Tick to add statement)

-

Engineer Rating - What rating would the customer give the visit?

- 0 - 😡

- 1 - 😡

- 2 - 😡

- 3 - ☹️

- 4 - ☹️

- 5 - ☹️

- 6 - ☹️

- 7 - 😕

- 8 - 😕

- 9 - 😀

- 10 - 😀

DAMAGE CLAIM

THIS IS A STAND ALONE FORM AND SHOULD NOT BE USED ALONG SIDE ANY OTHER SECTION OF THIS DOCUMENT

Job Details

-

Incident Number

-

Date of Incident

-

Location of Incident

-

Customer Details

Engineer Details

-

Engineer

-

Tech Number

-

Team Number

Person completing report

-

Prepared by

-

Date of TM site visit

Liability

-

In my opinion was this caused by a Sky visit or install?

-

Record Of Findings Full details giving reason for denying or accepting liability with photographic evidence including report and clearly stating liability accepted/ denied

-

Were there any witnesses?

-

Witness details if not the person reporting the incident (only required if not the customer)

Photographs & Drawings

-

Add pictures to support findings

-

Add drawing to support findings (if required)

-

Add drawing to support findings (if required)

Corrective Actions

-

Has the person reported been made aware of the incident?

-

H&S Dept notified?

-

Is further investigation required?

-

Who will carry out further investigation?

-

Has incident report been completed on SOLARS?

-

What corrective action has been taken to prevent a recurrence?

Customer

-

What action has been agreed with customer?

-

Customer Signature

Email completed document to claimshandling@bskyb.com

INVESTIGATION

-

Explanation of investigation (Reasons and findings)

-

Add pictures to support investigation

-

Is the Engineer present?

I certify that I attended an investigation meeting and will not disclose to any third party the information discussed at this meeting (other than for the purposes of seeking legal advice). Please note that any breach of this agreement may result in action under the company's disciplinary procedure.

-

Engineer

-

Firstly, thank you for meeting me. Before we go any further you've signed the confidentiality agreement which I remind you means that you cannot discuss the content of this meeting with anyone. Do you understand?

I am currently conducting an investigation and I would like to ask you some questions.

Please be as open and honest as you can because it's important to me that I am able to gather all the facts.

You should be aware that the notes from this discussion we have today may be used going forward in any formal process. This means that these notes may be provided to other employees who have been involved in the situation, if necessary to do so. -

Tick box to open dialogue

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

Tick for more text boxes

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

Tick for more text boxes

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

Tick for more text boxes

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

Tick for more text boxes

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

Tick for more text boxes

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

Tick for more text boxes

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

Tick for more text boxes

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

Tick for more text boxes

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

Tick for more text boxes

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

Tick for more text boxes

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

Is there anything else regarding the incident that I have not asked which you feel may be relevant or that I need to look into?

-

Engineer

-

I have no further questions at this time however I may need to speak to you again.

I will finish my investigation as quickly as possible and let you know where we go from here. -

Has this investigation resulted in a suspension from duty?

-

For the reasons discussed today you are now suspended from the work place on full pay until these matters can be fully investigated. In the first instance you will be suspended until -

-

This matter will be kept confidential. If necessary your colleagues will be informed that your absence is for personal reasons.

In the meantime we may need to talk to you about this issue during your suspension so you should be available for contact and to attend meetings if necessary during your normal working hours. You will be advised of the outcome of the investigation as soon as possible.

Should you for any reason need to speak to one of your work colleagues or to come into your place of work you should contact me in the first instance for prior authorisation.

If you would like any advice or guidance in relation to company polices or processes during your period of suspension please contact ER.

Reopen Visit Type and include 'IDD' if required substituting 'Engineer' with customer, witness etc.

COACHING

-

Reason for coaching

- NPS

- Technical

- Customer Service

- Quality

- Safety

- Other

-

Pre visit comments - What outcome is hoping to be achieved?

-

Coach on site observations/ comments

-

Engineer comments - What will you take away from today's session?

-

Follow up details (if required)

-

Review date

-

Add pictures to support

EQUIPMENT INSPECTION (All inspections are carried out in accordance with the current HS&S Maintenance Schedules)

TAG COLOUR - GREEN (OCTOBER/MARCH 2018)

THIS IS A STAND ALONE FORM AND SHOULD NOT BE USED ALONG SIDE ANY OTHER SECTION OF THIS DOCUMENT

-

Engineer Type

Hard Hat - This item have a working life (refer to ref guide)

-

Hard Hat

-

Hard Hat Date/ Serial no

-

Hop Up

-

Ear Protection

-

Ear Protection Type

-

Eye Protection

-

Eye Protection Type

-

Head Torch

-

Hi-Viz Vest

-

Knee Pads

-

Dust Masks

-

Boots

-

Rubber Mat

-

Antiseptic Wipes

-

First Aid Kit Expiry Date

For Current working Life Guideline Please Refer to the Equipment Inspection Guide for Rope Access Equipment

-

Heightec Comfort Seat (MWSI)

-

Heightec Comfort Seat (MWSI) - Serial Number Date Of Manufacture

-

Sling Rock Twin Leg Kernmantle Lanyard c/w Scaff Hooks

-

Sling Rock Twin Leg Kernmantle Lanyard c/w Scaff Hooks - Serial Number Date Of Manufacture

-

11MM Dynamic Rope - 50 mtr

-

11MM Dynamic Rope - 50 mtr Serial Number Date Of Manufacture

-

Sling Rock Harness

-

Sling Rock Harness- Serial Number Date Of Manufacture

-

Rocker (Safety Back up Device ) c/w Sling + 2 Karabiners

-

Rocker- Serial Number Date Of Manufacture

-

Hand Ascender Foot Loop + 1 Karabiner

-

Hand Ascender Foot Loop - Serial Number Date Of Manufacture

-

Short Cows Tail

-

Short Cows Tail - Serial Number Date Of Manufacture

-

Chest Ascender + Strap

-

Chest Ascender + Strap - Serial Number Date Of Manufacture

-

iD Descender Unit + 1 Karabiner

-

iD Descender - Serial Number Date Of Manufacture

-

10mm Delta Maillon Rapide 10MM

-

10mm Semi-circular Maillon 10MM

-

10mm Screwgate Karabiners

-

Set Of Cows Tails 11mm Dynamic Rope

-

Set Of Cows Tails 11mm Dynamic Rope - Serial Number Date Of Manufacture

-

SAT iD Ascender/Descender + Karabiner

-

SAT iD Ascender/Descender - Serial Number Date Of Manufacture

-

Single Sheave Pulley Block

-

Single Sheave Pulley Block - Serial Number Date Of Manufacture

-

Double Sheave Pulley Block

-

Double Sheave Pulley Block- Serial Number Date Of Manufacture

-

7mm Plastic Coated Wire Strops + 2 Delta Maillons

-

7mm Plastic Coated Wire Strops - Serial Number Date Of Manufacture

-

1.2mtr Sewn Endless Anchor Webbing Slings

-

1.2mtr Sewn Endless Anchor Webbing Slings - Serial Number Date Of Manufacture

-

1mtr Sewn Endless Sling

-

1mtr Sewn Endless Sling- Serial Number Date Of Manufacture

-

1mtr Canvas Rope Protector

-

SAT Sky Safety Helmet

-

SAT Sky Safety Helmet - Serial Number Date Of Manufacture

-

30lt Kit Bag

-

Personal Kit Bag

-

Fish Knife

-

Declaration -- I Confirm on Behalf of Sky UK the above listed equipment has been inspected in accordance with the Manufacturers Guidelines and training received . All Equipment listed above meets the required BS and/or EN Standards appropriate to that equipment as listed in the Maintenance Schedule for Rope Access Equipment

Harness/ Cows Tail - These items have a working life (refer to ref guide)

-

Harness

-

Harness Serial no/ Date of manufacture

-

Cows Tail

-

Cows Tail Serial no/ Date

Kernmantle Rope/ Retractable Safety Line - These items have a working life (refer to ref guide)

-

15M Rope

-

15M Rope Serial no/ Date

-

10M Rope

-

10M Serial no/ Date

-

5M Rope

-

5M Serial no/ Date

-

Rope Grab

Continuous Loop Webbing Sling Life - These items have a working life (refer to ref guide)

-

Continuous Loop Webbing Sling

-

Continuous Loop Webbing Sling Dates

-

Adjustable (ratchet) Webbing Strap

-

10M Strap with Ratchet

-

Karabiners

Chimney Strop Life - These items have a working life (refer to ref guide)

-

Chimney Strop

-

Chimney Strop Serial no/ Date

Soft Sling Life - These items have a working life (refer to ref guide)

-

Soft Slings (part of chimney kit)

-

Soft Slings Dates

-

Microlite

-

Ladder Mate

-

Ladder Spike

-

Gravel Bag

-

Cones X2

-

Crawl Boards X2

-

10mm Eyebolts

-

12mm Eyebolts

-

20mm Eyebolt

Hard Hat - This item have a working life (refer to ref guide)

-

Hard Hat

-

Hard Hat Date/ Serial no

-

Ladders

-

Step Ladder/ Combi Ladder

-

CAT Ladder

-

Ear Protection

-

Ear Protection Type

-

Eye Protection

-

Eye Protection Type

-

Draper Floodlight (Ground mounted)

-

Draper Floodlight (Tripod mounted)

-

Peli Floodlight

-

Knee Pads

-

Manual Handling Gloves

-

Hi-Viz Vest

-

Dust Masks

-

Boots

-

Drill Harness

-

Bosch Detector

-

First Aid Kit Expiry Date

-

Portable Appliance Testing (PAT) Date

-

SPECIALIST ENGINEER

DAT/ SAT Only

-

50M Rope

-

50M Rope Serial no/ Date

-

Rocker

-

Rocker Serial no

-

Safety Ascender/Descender Device

-

30M x 7mm Static ACC. Cord

-

Axel Belay Device

-

Wire Rope Slings

-

Wire Rope Slings Serial nos

-

Delta Mailon

-

Rope Protecters

-

Pulley Blocks (fixed sheave)

-

RGH16 Harness (life same as DTH)

-

RGH16 Serial no/ Date

-

Silverstar Helmet

-

Silverstar Helmet Serial no/ Date

-

8 Rung Extension Ladder

-

Ladder Clamp

-

Conservatory Bearer Bar X2

-

CAMP 30ltr Kit Bag

-

NOTE - If any items are found to be defective they are to be isolated and replaced as soon as possible.

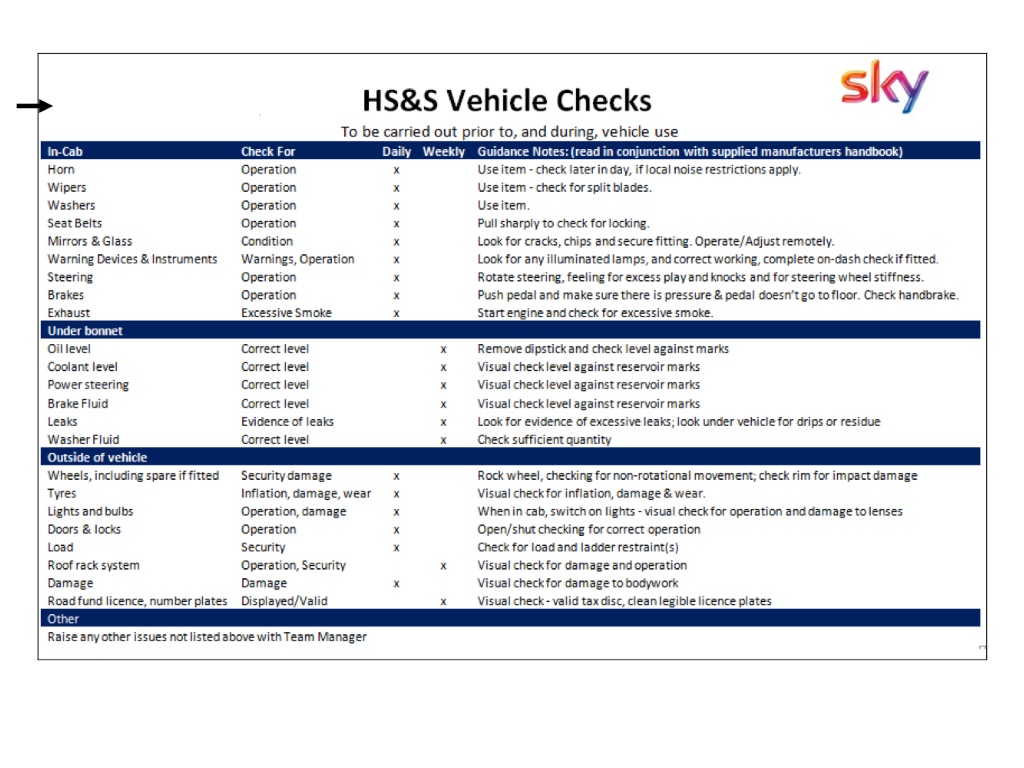

Engineers Van Safety Check

-

Engineers are required to carry out daily and weekly safety checks on their vehicles. From September 2013, to ensure that the engineer is clear about how to carry out these checks, Team Managers should carry out the following as part of the six monthly safety checks.

-

Van Registration

-

Ask the Engineer to demonstrate how they carry out their daily and weekly checks, using the HS&S Vehicle checklist PDF on their iPads

-

Visually check the items alongside the Engineer. If any defects are found record them in the comments section.

-

Discuss any items, as appropriate, to test the Engineers understanding.

-

Ask the Engineer if they have had any issues in the past six months, and whether these issues have been dealt with. If any issues are outstanding, record in the comments section.

-

Where the Engineer shows any areas for improvement, coach accordingly and comment accordingly.

-

Is Vehicle Height Sticker clearly visible on the dash board?

-

Comments

-

HS&S Vehicle Checks Reference Guide (tick box to view)

-

ENGINEER DECLARATION: I confirm that by signing below the listed equipment has been issued to and is used by me. That no other equipment is used without authorisation, and a full inspection has been carried out by the HS&S - PPE & Equipment Examiner. I also confirm that I have carried out the vehicle checks in accordance with the Fleet directives.

Please ensure to upload a copy of this Equipment Inspection to the relevant team folder on the designated Office365 site

121

-

Reason for 121

- Praise/ Reward

- NPS

- Revisits

- Customer Service

- Technical

- Business Update

- Safety

- DriveSafe

- Personal Matter

- Other

-

Current NPS YTD

- Below 65

- 65

- 66

- 67

- 68

- 69

- 70

- 71

- 72

- 73

- 74

- 75

- 76

- 77

- 78

- 79

- 80

- 81

- 82

- 83

- 84

- 85

- 86

- 87

- 88

- 89

- 90

- 91

- 92

- 93

- 94

- 95

- 96

- 97

- 98

- 99

- 100

-

Current revisit KPI % YTD

- Over 5

- 4.1 - 5

- 3.1 - 4

- 2.1 - 3

- 1.1 - 2

- 0.1 - 1

- 0

-

Details

-

Tick box to open dialogue

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

Tick for more text boxes

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

Tick for more text boxes

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

Tick for more text boxes

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

Add pictures to support 121

-

Agreed actions (if any to be reviewed)

IDD

-

Reason for ROD

-

Time and date of incident

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

Tick for more text boxes

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

Tick for more text boxes

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

Tick for more text boxes

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

Tick for more text boxes

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

Tick for more text boxes

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

Tick for more text boxes

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

Tick for more text boxes

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

Tick for more text boxes

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Engineer

-

TM

-

Add media to support ROD

If more text boxes are needed please start a new IDD form

-

Is further action required? (Last ROD page only)

If this is a breach of H&S the incident is required to be reported on SOLARS as a 'Near Miss'

-

Has this ROD resulted in a suspension from duty?

-

For the reasons discussed today you are now suspended from the work place on full pay until these matters can be fully investigated. In the first instance you will be suspended until -

-

This matter will be kept confidential. If necessary your colleagues will be informed that your absence is for personal reasons.

In the meantime we may need to talk to you about this issue during your suspension so you should be available for contact and to attend meetings if necessary during your normal working hours. You will be advised of the outcome of the investigation as soon as possible.

Should you for any reason need to speak to one of your work colleagues or to come into your place of work you should contact me in the first instance for prior authorisation.

If you would like any advice or guidance in relation to company polices or processes during your period of suspension please contact ER. -

Case Justification Form

-

Please note to ensure we are operating efficiently there are mandatory parts of this form that need to be completed before submitting.

Please review all information has been provided before submitting. -

Employee Business Area/ Dept

-

Investigation Manager

-

Investigation Manager Contact Number

-

Details of reason for investigation (please detail the reason you started an investigation, summarise the discussion of each meeting and other findings)

-

Summary of findings and recommendations (please detail the specific reason why you believe there is a cases to answer)

-

CHECKLIST OF DOCUMENTATION

MANDATORY DOCUMENTATION REQUIRED -

Investigation notes and relevant witness statements (Please ensure all customer details including names and addresses are removed before submitting. *It is preferable to use job numbers as a reference

-

FOR HEALTH AND SAFETY CASES

-

Photographs (eg - Photograph for job number xxxxxxxxx. Point of interest ie - The eyebolt has not been drilled (explain what the photograph refers to). Please write job numbers on the photographs)

-

MFT print out/ paper risk assessment (If information is required from the risk assessment)

-

HomeSafe Records (Please ensure records are dated, page numbers on each page and job numbers)

-

Post Checks (Please ensure all have job numbers and dates on pages)

-

Training Records (Detailing H&S training. This can be obtained by emailing Training Planning and providing employee name and ID number)

-

FOR DRILLING CASES

-

Relevant Policy (Please detail the policy which the investigation relates to eg - Disciplinary Policy)

-

Current Sanction Details (If applicable, please detail any current sanction)

-

Suspension Start Date or Extension Date

-

Disciplinary Details

-

Venue

-

Date and Time

-

Chair Name and Contact Number

PROBATION DISCUSSION DOCUMENT

-

Week of Probation

-

Type Of Meeting

-

Welcome & Specific Team Information

-

Add media to support

-

Expectations for Performance, Attendance & Conduct

-

Add media to support

-

Targets/ Objectives

-

Add media to support

-

Support Measures or Adjustments

-

Add media to support

-

Dates & Times of Weekly 121's & Interim Review

-

Add media to support

-

Additional Comments

-

Add media to support

-

What's gone well? - Encourage & praise good performance/ behaviours

-

Add media to support

-

Progress against targets/ objectives set in Introductory Meeting

-

Add media to support

-

Any concerns around Attendance, Performance or Conduct?

-

Add media to support

-

Expectations moving forward

-

Add media to support

-

Support Measures or Adjustments

-

Add media to support

-

Additional Comments

-

Add media to support

-

What's gone well? - Encourage & praise good performance/ behaviours

-

Add media to support

-

Progress against Targets/ Objectives set in Introductory Meeting & 121's

-

Add media to support

-

Any concerns around Attendance, Performance or Conduct?

-

Add media to support

-

Expectations moving forward - Set expectations if improvement(s) not met

-

Add media to support

-

Support Measures or Adjustments

-

Add media to support

-

Date of Final Probation Review Meeting

-

Additional Comments

-

Add media to support

-

Discuss overall Attendance, Performance & Behaviours

-

Outcome

-

Congratulate on successfully completing probation period & celebrate success!

-

Set expectations moving forward

-

Add media to support

-

Explain reason for extension

-

Expected End Date -Duration of extension (no less than 4 weeks & no longer than 13)

-

Agreed improvements expected

-

Add media to support

-

Agreed support required if appropriate

-

Add media to support

-

Set expectation that if improvement not made this could result in non-confirmation of probation.

-

Additional Comments

-

Add media to support

-

TM

-

Engineer