Title Page

-

Document No.

-

Audit Title

-

Client / Site

-

Conducted on

-

Prepared by

-

Location

-

Personnel

1. Section 1. The Facility

-

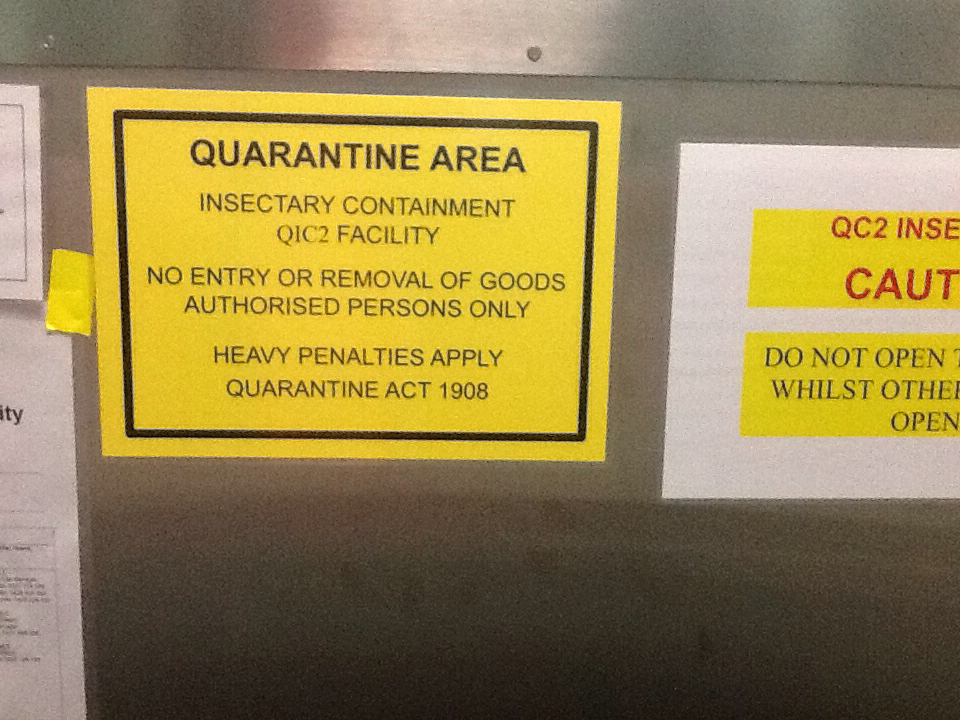

1. Is the quarantine facility secure from unauthorised personnel.

-

2. Is correct signage clearly visible at the facility entrance.<br>Signage must state ' Insectary Containment - QIC2 Facility

-

3. Is the entrance to the work area via an anteroom. <br>Is it of suitable size to allow materials, equipment and trolleys to pass through with one door closed at all times.

-

4. Do the anteroom doors open inward and are self closing. <br>Is there drop down seals on the doors and function correctly.

-

5. Is there a viewing pane in each door and a method for preventing more than one door being open at one time.

-

6. Is there a suitable insect trap provided in the anteroom.

-

7. Are coat hooks provided for gowns in the anteroom or in the entrance to the work area.

-

8. Is there a directional flow of air into the facility.

-

9. Is the facility a fully enclosed space bounded by walls, doors and windows.

-

10. Is there 250 micron mesh screens in the walls and ceiling.

-

11. Are the walls and ceilings painted in light colour to assist with sightings of non contained insects.

-

12. Are surfaces maintained so they remain smooth and impervious to water, and resistant to damage from cleaning agents and disinfectants in use:<br>-walls, floors, benches<br>-furniture including seating<br>

-

13. Open spaces between and under benches, cabinets and equipment are accessible for decontamination.

-

14. Are all services penetrations and light fitting sealed.

-

15. Are sink outlets fitted with 100 micron mesh baskets arresters.

-

16. Is the quarantine work area separate from office write up space.<br>

-

17. Is an effective pest management system in place.

Section 2. Operating Procedures

-

18. Correct PPE is being worn when work undertaken.

-

19. Are gowns placed back on coat hooks when work completed and not left on back of chairs.

-

20. Provision for staff to check that insects are not on any part of their body when exiting the facility.

-

21. Procedures in place to ensure quarantine and non quarantine materials are segregated.

-

22. Are all rearing trays and containers holding viable quarantine material labelled with the common and scientific name of the organism.

-

23. Equipment decontaminated and recorded before being removed from the facility for repair.

Section 3. Class 5.2 Microbiological and Animal Facilities

-

24. Are class 2 biosafety cabinets available for the containment of aerosols.

-

25. Has the cabinets been tested by a qualified service provider within the last 12 months.

-

26. Has the HEPA filter in the IVC system been changed within the last 12 months.

-

27. Is there documentation to ensure HEPA filters are disposed of as quarantine waste.

-

28. Is the testing documentation available.

-

29. Is the vacuum trap set up correctly. Is there a 0.22 micron filter in place.

-

30. Are caps for centrifuge buckets available to contain aerosols when centrifuging.

-

31. Is all quarantine material and non quarantine material in incubators clearly labelled and segregated.

-

32. Are there drop down seals on the door to prevent escape from facility.

-

33. Is the caging system designed to contain the animals.

-

34. Are the cages labelled to clearly identify animals infected with quarantine material.

-

35. Is there a procedure in case of escape of animals from cages.

Section 4. Equipment

-

36.Is a hand free basin or dispenser available to wash hands to exit facility.

-

37. Is there a plumbed eyewash station in the facility. <br>Is it tested regularly.

-

38. Is all electrical equipment tagged and tested.

-

39. Is all equipment suitable for containing insects at all stages of life cycle.

-

40. How often are insect traps checked.

Section 5. Storage

-

41. Is quarantine and GMO material other than viable insects stored in the facility.

-

42.Are the storage areas clearly labelled with quarantine storage and biohazard symbols signs.

-

43. Is quarantine and GMO material stored outside the facility.

-

44. If yes, is the storage area clearly labelled with quarantine storage and biohazard symbol signs.

-

45. Is there a database or documentation to show the location of the stored material.

Section 6 Disinfection

-

46. Are disinfectants suitable for the material in use available.<br>Where applicable are they D of A approved.

-

47. Are they used at correct working concentration and within expiry date.

-

48. Are benches and biosafety cabinets disinfected at start and end of day and between procedures.

Section 7. Waste Disposal

-

49. Are all quarantine bins fitted with a lid and quarantine waste sign.

-

50. Is quarantine waste double bagged.

-

51. Is there a waste segregation procedure in place.

-

52. Are there lidded storage bins available for the temporary storage of waste prior to decontamination. <br>Are bins breakproof?<br>Are they clearly labelled.

Section 8. Decontamination

-

53. Is waste autoclaved out of facility prior to disposal.

-

54. Is the autoclave validated monthly.<br>What is the method of validation and are records of past 12 months available.

-

55. Is the autoclave calibrated annually and are records available.

-

56. Are the waste loads record in a log book and is run logged electronically and is there a print out available recording the run.

-

57. Is there a procedure in place to deal with a failed run.

-

58. What is the method for decontamination of quarantine waste water from the rearing rooms.

Section 9. Administration

-

59. Are the quarantine import permits available for material within the facility.

-

60. If non imported insects from another source are in the facility is this documented.

-

61. Is screen cleaning documented.

-

62. Are there relevant SOPs for the facility and are they within expiry period.

-

63.Are local induction records available.

-

64. Where necessary are staff quarantine approved and are accreditation records available.

-

65. Have staff completed OGTR on line training.

-

66.Are risk assessments available.

-

67. Are emergency contact numbers sighted

-

68. Are fire extinguishers checked.

Section 10. Other Comments

-

Add media

Sign off

-

Inspection Representative

-

Safety Representative