Information

-

Project Name

-

Client

-

Conducted on

-

Workgroup

-

Number of Employees

-

Job Titles

-

Prepared by

-

Location

-

Personnel (first and last name)

-

Audit Guidance: -All unsafe acts shall be stopped immediately. -Field Observations shall include photos for both safe and unsafe operations. Photos should be annotated with what the observer is focused on at the time of the audit. -Any item marked as a deficiency shall have a photo (if possible) and a detailed description. -All comments should identify those crew members performing the task correctly and/or incorrectly. -Equipment being inspected shall be listed and/or have a photo with the unit number displayed. -All audits shall be reviewed with the PIC prior to departure from the site. Corrective actions shall be assigned with due dates and noted on the audit. -Any audits being forwarded to the client shall be reviewed by more than one safety team member prior to being sent.

-

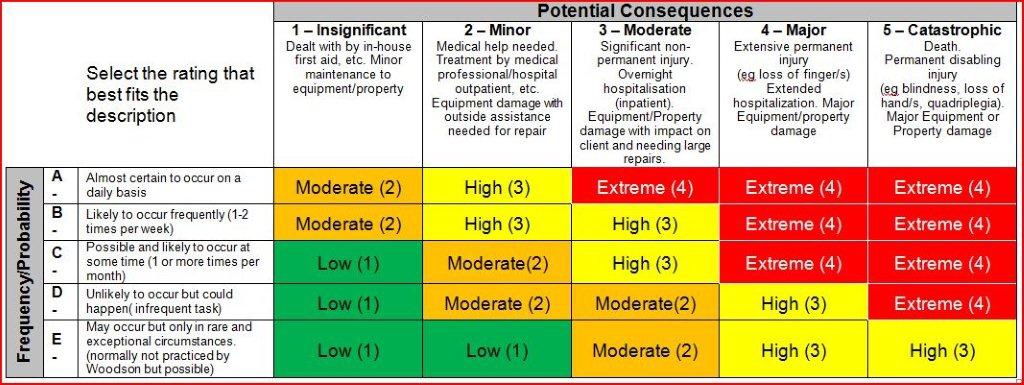

All audit findings shall have an assigned weight (1-4) assigned per the below matrix. Document the weighted number rating in the comment section associated with the applicable question.

Communication

-

When was the last time you were coached from a member of management on safety?

-

Prior to making a decision, do you think Likelihood or Consequences?

-

Human Performance tools observed and bieng utilized correctly?

-

Three part communication utilized?

-

Proper use of hand signals and flagging techniques? Spotters used appropriately?

-

Hand Held radios mounted, charged and being utilized properly? Radio harness being utilized?

Procedures and Documents

-

Tailboard/Job Hazard/Driving assessment completed?

-

Weekly inspection sheets complete?

-

Paperwork (Private Motor Carrier License, Haz-Mat Registration, Vehicle Registration(s), Insurance Certificate, IFTA License & Stickers, Annual Inspections(s).392.2-396.17?

-

Are SDS available for all hazardous chemicals on site ?

Displays and Labels

-

Is the work site properly marked and/or barricaded? 10' rule in compliance?

-

Is appropriate signage in place on entry?

-

Early warning signs placed for overhead/underground hazards?

Environmental

-

Secondary containment in place? Units parked away from waterways?

-

Spill kits available and stocked? Spill response understood and practiced? Spills reported?

Schedule

-

Crew schedules identified and fatigue management addressed?

-

Schedules communicated for multiple operations?

Work Practices

-

TOC/DOC notified ?

-

Taglines when moving suspended loads?

-

Are proper lifting/carrying techniques utilized?

-

Are proper pushing/pulling techniques utilized?

-

Are employees using 3 points of contact when ascending, descending, and climbing?

-

Are cell phones being use appropriately?

-

Is employee mindful of line of fire and pinch points?

-

Are all compartments and fill caps locked when machines are unattended?

-

Proper rigging, lifting, hand signals, and good communication being utilized?

-

Is the housekeeping good?

Work Planning

-

Job Plan (does everyone know duties)?Have the job hazards been identified, prioritized, and documented?Work area clearly defined on JSA?Has an effective control/mitigation plan for identified hazards been developed?

-

Poison Ivy mitigation plan?

-

Has the emergency plan been documented and understood?

-

Were required Human Performance tools discussed/identified/used?

-

Is fall protection equipment in good condition and rescue plan in place?

-

If more than one crew present (contract or Entergy), lead(s) are identified and communication is occuring?

-

Animals, insects and plants mitigated?

-

One call locates completed?

Supervision

-

Emphasis of schedule exceeding safe work?

-

Supervision interfacing with workers?

-

Supervision verifying the job hazard analysis/job plan is being followed?

-

Crew lead demonstrated leadership ability?

Training/Qualification

-

Powersafe complete and up to date

-

Crew Members qualified for task being performed?

-

Crew knowledgeable of previous weeks lunch time training?

Change Management

-

JSA updated periodically and whenever work task changes? Time stamped at lunch?

External Influence

-

Weather conditions discussed and documented?

-

Heat/cold mitigation plan in use and documented?

-

Public encrouchment on job site discussed and documented on JSA?

System/Equipment Operation

-

Are seat belts being used on applicable equipment while in operation?

-

Parking Brake (Apply) 393.41?

-

All PPE in good order and utilized? hard hat, eye protection, hearing protection, vest, footwear, gloves, glove clips, face shield, chaps etc.

-

Safe use of chainsaws?

-

Are dielectric overshoes or EH boots being used?

-

If applicable, Is FR clothing being worn?

-

If applicable, 100% fall protection being utilized?

-

Equipment Parked over bare dirt, end to end or side by side. N/A if not seen at time of audit

Personnel and Materials Management

-

Sufficient personnel assigned to task?

-

Adequate materials provided to complete task?

Equipment Selection and use

-

Is all equipment set up for safe use (outriggers set up properly as applicable)?

-

Are fire extinguishers on site, within date, and in good working order?

-

GFI equipment and extension cords in good working order?

-

Are ladders (fiberglass only) in good condition and tied off as needed?

-

If applicable, Is PVD operational?

-

Are guards in place on grinders, portable saws, etc?

-

are uptime kits on location?

-

Chainsaw guards and safeties in place?

-

Fuel tanks full or left full? water drained from fuel system?

-

Non-frayed winch lines? oiled?

-

Are the proper tools for the job being utilized, and are tools in good condition with no modifications?

-

Eye wash station or solution in good working order and readily available?

Management

-

Short service employee's identified and assigned mentors? On JSA?

-

Timely response to known problems?

-

Policies, practices, procedures properly defined?

-

incidents/near misses reported in a timely manner?

Basic Machine Maintenance/Testing

-

Unit photos

-

Has the crew performed and documented an inspection of the forklift/ manlift/Skytrack prior to work to assure equipment is in safe operating condition?

-

Are safety/medical/first aid equipment/ goods on site and within date, including gel blankets?

-

Di-electric testing on booms completed?

-

Compressors and other equipment covered?

-

Slings and rigging properly inspected and adequate?

-

Back up alarms working properly

-

All BMM completed in accordance with Woodson policy? cab clean, greased and wiped, engine compartment clean, oil at correct level, mirrors clean, windshield in good order, transmission oil correct level, windows clean (pledge), wipers ok, coolant levels good, radiator clean, heater/defroster working, tires and undercarriage clean, leaks, air filters, belts, hydraulic hoses in good condition.

-

Does operator allow 10 minutes to warm up after starting engine. N/A if not seen at time of inspection?

-

Tires/tracks, and undercarriage inspected for excessive wear and loose components, including valve caps (note last rotation)?

-

Is equipment damage/malfunctions recorded on daily/weekly checklist?

-

All equipment lights working properly?

-

Gauges working properly? all controls labeled?

Design Configuration

-

Are appropriate DOT signs and cones in place?

-

Equipment properly barricaded when work is performed near live voltage or when grounded?

Summary and signatures

-

Positive observations. List crew members and specific items they are doing correctly:

-

Inspectors signature

-

Crew lead signature