PLATE INSPECTION GENERAL

-

DOCUMENT No.: QIPF-HPR-1

-

Receiving Inspection Procedure: QIP-HPR-1

-

AUDIT TITLE: HEADER PLATE RECEIVING CHECKLIST

-

CONDUCTED ON

-

PREPARED BY

-

LOCATION

-

P.O. NUMBER:

-

ETR JOB SERIAL NUMBER(S) (ex: 1111.2222.001 thru 010)

EQUIPMENT FOR THICKNESS READINGS

-

CALIPER

-

UT METER

-

MICROMETER

-

OTHER

THICKNESS COMPLIANCE

-

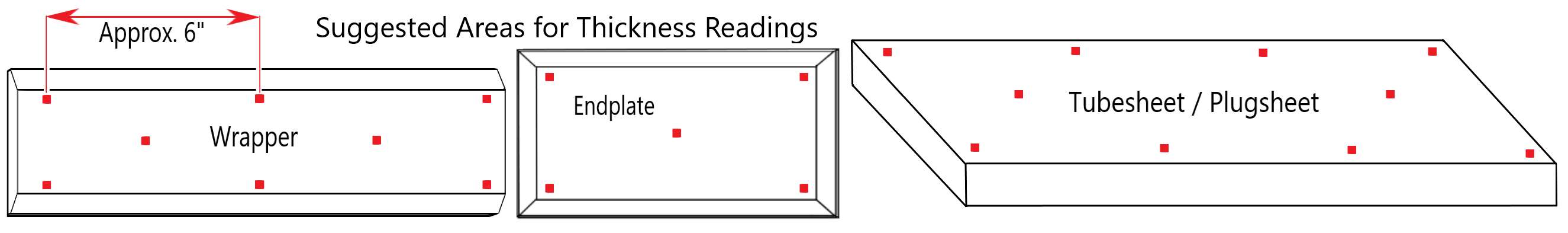

Suggested Areas for Thickness Readings

EXAMINATION RESULTS

Heat No. / Code

-

Line 1:

-

Line 2:

-

Line 3:

-

Line 4:

-

Line 5:

-

Line 6:

-

Line 7:

-

Line 8:

-

Line 9:

-

Line 10:

Type:

-

Line 1: Tubesheet / Plugsheet / Wrapper / Endplate

-

Line 2: Tubesheet / Plugsheet / Wrapper / Endplate

-

Line 3: Tubesheet / Plugsheet / Wrapper / Endplate

-

Line 4: Tubesheet / Plugsheet / Wrapper / Endplate

-

Line 5: Tubesheet / Plugsheet / Wrapper / Endplate

-

Line 6: Tubesheet / Plugsheet / Wrapper / Endplate

-

Line 7: Tubesheet / Plugsheet / Wrapper / Endplate

-

Line 8: Tubesheet / Plugsheet / Wrapper / Endplate

-

Line 9: Tubesheet / Plugsheet / Wrapper / Endplate

-

Line 10: Tubesheet / Plugsheet / Wrapper / Endplate

Quantity

-

Line 1:

-

Line 2:

-

Line 3:

-

Line 4:

-

Line 5:

-

Line 6:

-

Line 7:

-

Line 8:

-

Line 9:

-

Line 10:

Visible Defects (see list below) (Yes or No)

-

Line 1:

-

Line 2:

-

Line 3:

-

Line 4:

-

Line 5:

-

Line 6:

-

Line 7:

-

Line 8:

-

Line 9:

-

Line 10:

Plate Dimensions within Tolerance (Yes or No)

-

Line 1:

-

Line 2:

-

Line 3:

-

Line 4:

-

Line 5:

-

Line 6:

-

Line 7:

-

Line 8:

-

Line 9:

-

Line 10:

Thickness Within Tolerance (+0"min) (Yes or No)

-

Line 1:

-

Line 2:

-

Line 3:

-

Line 4:

-

Line 5:

-

Line 6:

-

Line 7:

-

Line 8:

-

Line 9:

-

Line 10:

Average Thickness

-

Line 1:

-

Line 2:

-

Line 3:

-

Line 4:

-

Line 5:

-

Line 6:

-

Line 7:

-

Line 8:

-

Line 9:

-

Line 10:

FLAWS / DEFECTS

Laminations

-

Line 1:

-

Line 2:

-

Line 3:

-

Line 4:

-

Line 5:

-

Line 6:

-

Line 7:

-

Line 8:

-

Line 9:

-

Line 10:

Folds

-

Line 1:

-

Line 2:

-

Line 3:

-

Line 4:

-

Line 5:

-

Line 6:

-

Line 7:

-

Line 8:

-

Line 9:

-

Line 10:

Pitting

-

Line 1:

-

Line 2:

-

Line 3:

-

Line 4:

-

Line 5:

-

Line 6:

-

Line 7:

-

Line 8:

-

Line 9:

-

Line 10:

Cuts

-

Line 1:

-

Line 2:

-

Line 3:

-

Line 4:

-

Line 5:

-

Line 6:

-

Line 7:

-

Line 8:

-

Line 9:

-

Line 10:

Out of Square

-

Line 1:

-

Line 2:

-

Line 3:

-

Line 4:

-

Line 5:

-

Line 6:

-

Line 7:

-

Line 8:

-

Line 9:

-

Line 10:

Wrong Dimensions

-

Line 1:

-

Line 2:

-

Line 3:

-

Line 4:

-

Line 5:

-

Line 6:

-

Line 7:

-

Line 8:

-

Line 9:

-

Line 10:

Other

-

Line 1:

-

Line 2:

-

Line 3:

-

Line 4:

-

Line 5:

-

Line 6:

-

Line 7:

-

Line 8:

-

Line 9:

-

Line 10:

MTRs

-

Heat #s Match

-

MTR Data Correct

-

Meets Section II Requirements

REJECTED MATERIALS

-

Item Description

-

Heat No./Code

-

Reason for Rejection

COMMENT SECTION

-

Comments:

SIGNATURES

-

Receiving Inspector Name:

-

Receiving Inspector Signature: