Title Page

-

Site conducted

-

Conducted on

-

Prepared by

-

Location

Workplace Safety and Environmental Inspection

-

This PJL group safety audit will gather information to assess the risks and hazards in the workplace. Please complete the audit and add any evidence you feel is necessary

LIGHTING

-

All lights working

-

Sufficient Lighting

-

Windows clean / undamaged

VENTILATION

-

Natural airflow and air extraction

-

Mechanical (include A/C, fans etc.)

-

Filters clean / inspected

-

Free from hazards or flammable material build up

AMENITIES

-

Hygienic toilets / urinals

-

Hygienic kitchen / crib room

-

Fridge and cooking appliances clean

-

Hygienic showers / change rooms

-

Adequate supply of drinking water

EMERGENCY

-

Exits identifies

-

Exit lights illuminated

-

Exit doors and equipment unobstructed

-

Current version evacuation plan in place

-

Evacuation plan tested in previous year

-

Eye wash clean, accessible and serviceable

-

Emergency shower accessible and serviceable

FIRE PROTECTION AND PREVENTION

-

Extinguishers accessible

-

Signs visible

-

Signs indicate type of equipment

-

Signs to standard

-

Inspection tags / seals in date

-

Equipment in good condition

FIRST AID FACILITIES

-

Location accessible

-

Clean and fully stocked

-

First Aid attendants names visible and current

-

Emergency procedure and phone numbers visible

-

Inspected within previous 6 months

BUILDINGS AND FLOORS

-

Building free from damage

-

Floor surface good / oil free

-

Aisles good width, safe and free of obstructions

-

Stairs to approved standards

AISLES AND STORAGE

-

Good demarcation

-

Surfaces in good condition (not worn)

-

Free of clutter / obstructions

STACKING AND STORAGE

-

Racks secure against falling

-

Sufficient racks / areas for storage

-

Clear access and egress

-

Load ratings obvious

WASH DOWN BAY

-

Clean

-

Pumped out regularly

-

Operating instructions available

PLANT AND YARD

-

Free of redundant plant

-

Free of redundant material

-

Plant and yard tidy

-

Traffic Management Plan in place

WASTE / SCRAP REMOVAL

-

Sufficient bins

-

Adequate removal / emptying

-

Waste segregated correctly

PORTABLE ELECTRICAL EQUIPMENT

-

All items identified and on register

-

Cables or plugs undamaged

-

Tools or leads undamaged

-

Stored appropriately

-

Current inspection tag (> 32v)

EARTH LEAKAGE

-

Complete site coverage

-

Tested regularly by a competent person

-

Inspection tag attached

ELECTRICAL INSTALLATIONS

-

Electrical equipment safe

-

Access to switchgear/substations restricted

-

Wires are not exposed

-

Sheaths / cable guides / conduits are undamaged

MACHINE GUARDING

-

Machines comply with appropriate standards

-

Guards in place

-

Guards secured appropriately

-

All nip points guarded

BENCH GRINDERS, DRILLS AND SAWS

-

Guards in place and serviceable

-

Bench grinder wheel in good condition

-

Bench grinder tool rest < 2mm gap to wheel

-

Double eye protection sign installed near grinders

-

Face shields available and clean

-

Saw blades are undamaged

LOCK OUT SYSTEM AND USAGE

-

Written procedure available

-

Procedure covers all energy sources

-

Switches are lockable

-

Tags and locks available

SWITCHES, ISOLATORS, VALVES AND CONTROLS

-

All items correctly labelled

-

Emergency stop buttons red in colour

LADDERS, HANDRAILS AND WALKWAYS

-

Comply with relevant standard

-

Toe boards fitted to stairs / landings

-

Minimum one handrail on stairways

-

Portable ladders inspected / tested

LIFTING GEAR AND MACHINERY

-

All items identified and on register

-

All items are in good condition (not defective)

-

SWL marked on all equipment

-

Safety latches in place

-

Regular inspections conducted

-

Stored correctly

-

Current inspection tag colour displayed

COMPRESSED AIR

-

Air hoses undamaged

-

Air outlets face downwards

-

All connections secure (no air leaks evident)

-

Safety clips in place

-

Connections are crimped (no hose clamps used)

ANGLE GRINDERS AND SANDERS

-

Items in good condition

-

Guards in place

-

Second handle available

-

Dead man switches fitted

-

Restricted use for 9" and 7" grinders

HAND TOOLS

-

Free of damage or defects

-

Free of sharp edges, mushroomed ends

-

Handles in good condition (not split)

-

Stored correctly

-

Clean of oil and grease

PRESSURE VESSELS

-

Maintained regularly

-

Safety relief valve operational

-

Receiver drained and free of moisture

-

Inspection date current (within 12 months)

GAS CYLINDERS

-

Cylinders stored vertically and secured

-

Segregation distances > 3 M (for other than class 2 gasses)

-

Correct flash back arrestors fitted

-

Transported correctly (vertically and secure)

-

Equipment in safe condition

CONNECTING PIPES FITTINGS AND HOSES

-

In good condition, no leaks

-

Pipes and lines correctly labelled

-

Safety clips used

FORKLIFT (random sample if more than one at site)

-

In good condition

-

Daily prestart inspection documented / regular

-

Isolated when unattended

-

Free of defective items

-

Operator competent and licenced

-

Seat belt in good condition

-

Safe access and egress from machine

-

Fire extinguisher fitted

-

Revolving light, reversing alarm & horn operational

-

Maintenance records current (M1)

LIGHT VEHICLE / SERVICE TRUCK (one sample)

-

In good condition

-

Daily prestart inspection documented / regular

-

Free of defective items

-

Seat belts in good condition

-

Operator competent and licenced

-

Fire extinguisher fitted

-

First Aid kit fitted

-

Items in rear secured

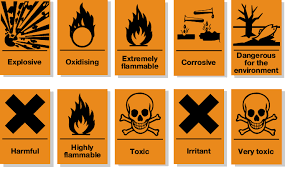

CHEMICALS AND SUBSTANCES

-

Products correctly labelled

-

SDS register available

-

Stored appropriately in bunding / containment

-

Segregation distance adhered to

-

Fumes extracted from storage areas

HEAD PROTECTION

-

Signs erected in applicable areas

-

Safety helmets provided

-

Safety helmets being worn as required

EYE AND FACE PROTECTION

-

Signs erected in applicable areas

-

Equipment provided

-

Worn correctly

HEARING PROTECTION

-

Signs erected in applicable areas

-

Equipment provided

-

Worn correctly

OTHER PPE

-

Harnesses / lanyards in good condition and used

-

Hand protection worn as required

-

Respiratory protection used

-

Sun protection / sunscreen used

-

Insect repellent available

-

Welding PPE in good condition

NOTICE BOARDS

-

In a conspicuous location

-

Suitable size

-

Up to date

-

Procedure in case of fire

-

CPR chart available

Policies

-

All relevant PJL Policies on display

-

Current version (signed by GM in previous 2 years)

PROCEDURES

-

Access available to written / electronic procedures

-

Workers can demonstrate electronic access

JSEA's COMPLETED OVER PAST THREE MONTHS

-

Total number and titles documented by auditor

TRA's COMPLETED OVER PAST THREE MONTHS

-

(select minimum of 25, document date range)

-

Workers understand basic risk analysis methods

SOP's COMPLETED BY SITE PERSONNEL

-

Were SOP's developed in the past 6 months

-

If yes, have they been numbered and published

CONSULTATION

-

(Use prompts e.g. Daily Planning Meetings, KAIZEN Board, Monthly Safety Meetings)

-

Workers can describe their role in consultation practices

CORRECTIVE ACTIONS

-

Any other hazards not mentioned?

-

Any corrective actions needed?

Complete

-

Name of auditor