Title Page

-

Inspection Date

-

Review Date

-

Site Location

-

Add media

-

Client

-

Team

-

Completed by

-

Operations Manager and Health & safety

-

INSTRUCTIONS:

-------------------------------------

1. Answer "Yes", "No", "N/A" for the questions below.

2. Add photos and notes by clicking on the paperclip icon.

3. To add a Corrective Measure click on the paperclip icon then "Add Action", provide a description, assign to a member, set priority and due date.

4. Complete audit by providing digital signature.

5. Share your report by exporting as PDF, Word, Excel or Web Link. -

Purpose of this visit.

-

Previous site inspection

-

Previous inspection date , if applicable.

-

All previous items closed

1. Management of Health and Safety

-

Are risk assessments and method statements (RAMS) available?

-

RAMS signed by operatives on site?

-

Have RAMS been reviewed within the last month?

-

Are the installers working to method statement procedures?

-

Are toolbox talks frequent and relevent to the work or current issues.

-

Recent topic?

-

Does there appear to be cooperation and coordination between trades?

-

Have there been any accidents, incidents or near-misses reported?

-

Have the issues been recorded or investigated?

-

Please create an action to close-out.

2. Workplace Safety

-

Is there safe access to and from the working area?

-

Is the working area adequately protected?

-

Are there adequate systems in place for fire safety and do they appear to be updated to reflect changes in site layout?

-

Are unnecessary materials removed from the working area and stored safely?

-

Is equipment safely stored?

-

Are the risks from slips, trips and falls satisfactory?

-

Are the welfare facilities in good order?

-

Is lighting satisfactory?

-

Adequate first aid provision?

-

Are people generally segregated from moving plant and machinery on site?

3. First Aid

-

Is a person appointed to take charge in an emergency?

4. Work Equipment

-

Is all the work equipment suitable for its intended use?

-

Is there an RCD available for cordless chargers or transformers?

-

Are all portable appliances inspected and tested?

-

Next test due

-

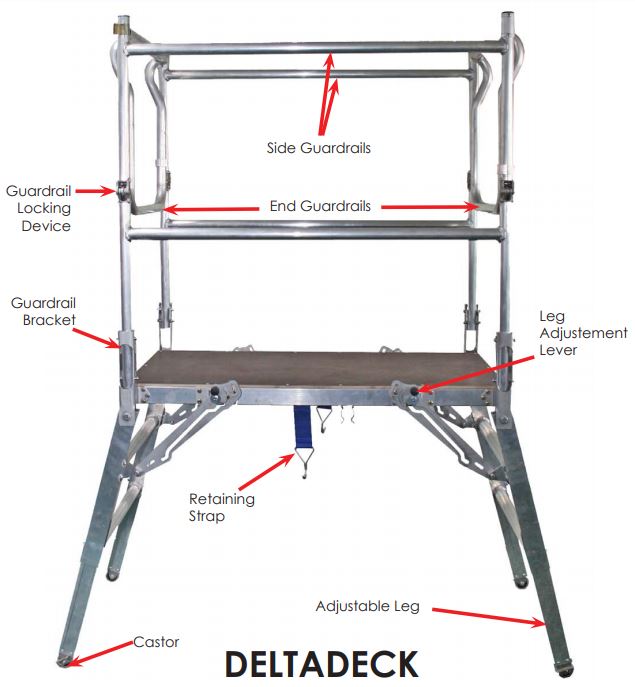

Is there any mobile access equipment and is it suitable – towers, etc? (Refer also to Section 8).

-

Are there any lifting operations or lifting equipment? e.g stillages etc

-

Briefly describe any lifting conditions.

-

Is lifting generally safe?

-

Are stillages being returned to HO regularly?

5. Materials, Environment and COSHH

-

Are COSHH assessments contained within RAMS?

-

Are materials, i.e. frames, glass and ancilleries stored appropriately?

-

Is waste segregated where necessary?

-

Is there anything else that may give rise to an environmental issue

6. Health

-

Is manual handling being carried out safely?

-

Is manual handling at a minimum?

-

Are noise levels generally acceptable?

-

Has an indicative noise sample been carried out?

-

Indicative sound level (informally taken from a smartphone app) dBA

-

Is drilling kept to a minimum ,reducing the effects of HAVS?

-

Is dust suppressed adequately?

-

Are face masks available?

7. Personal Protective Equipment

-

Correct PPE worn? Hi vis, Boots, Hard hat, glasses, Gloves Ear defenders

-

If there is additional PPE , is it being used correctly

8. Work at Height – Fall protection fall prevention, are any of the following being used? (if not - N/A).

-

Scaffold

-

Towers

-

Ladders and steps

-

Hop ups (Hop-ups minimum requirement is 600 x 600mm platform)

-

Podium

-

Is the planning of work at height generally acceptable?

Comments

-

Comments

-

Add media

Completion

-

Are there any further actions required?

-

Actions to close-out.

-

Issued to

-

Date

-

Signed