Information

-

Document No.

-

Audit Title

-

Prepared by

-

Date

-

Location

-

Personell

-

Close out sign off:

- Harley Beckham

- Gary Setterfield

- Daniel Caine

- Tommy Temple

- Alf Lapwood

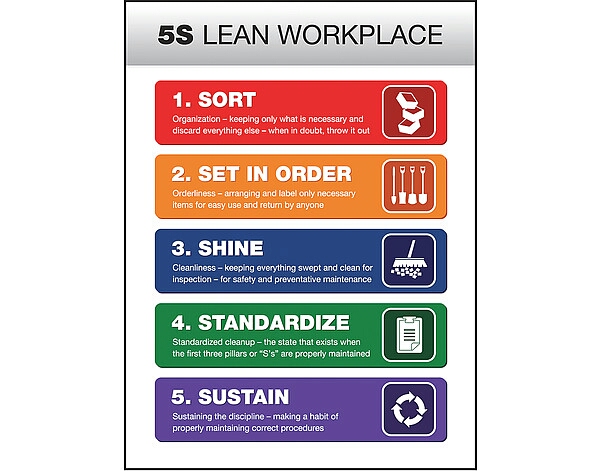

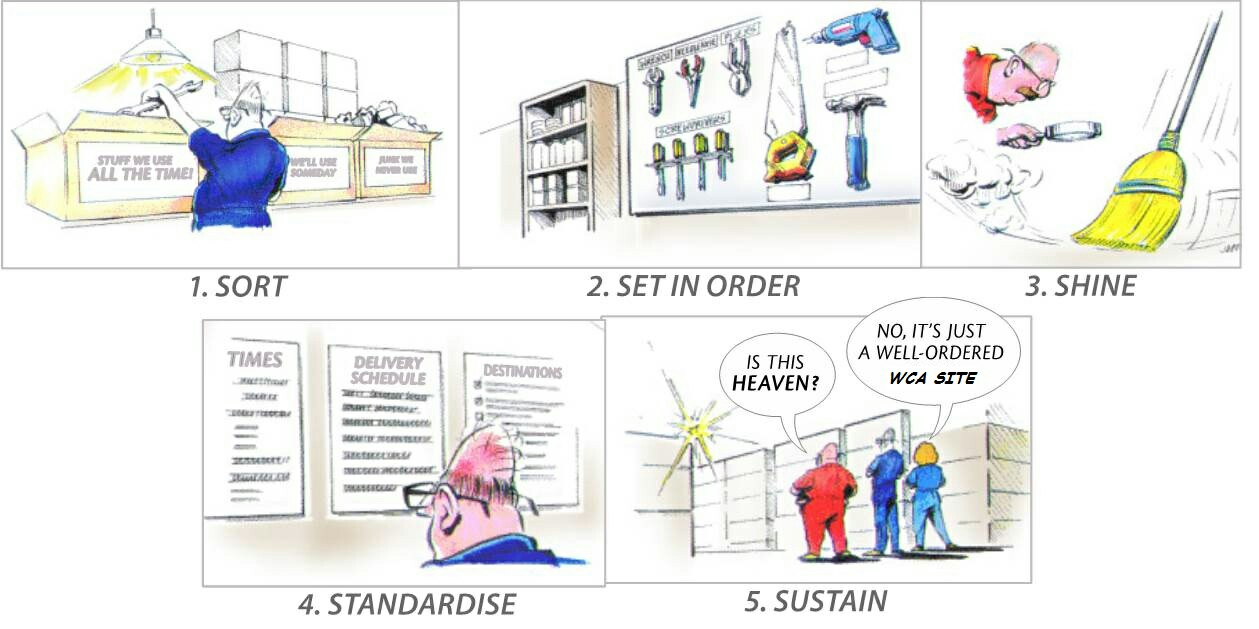

SORT

-

Sorting out necessary and unnecessary items. The items deemed unnecessary and not being used should be removed.

-

1. Are items (materials, tools, equipment) not needed for the job running removed from the active work area?

-

2. Is the area clearly marked (exclusion zones, walkways etc)?

-

3. Are all personal items (e.g. PPE) removed from the active work area?

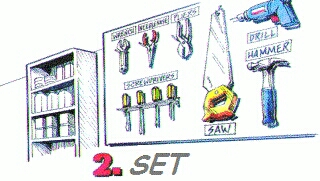

SET

-

A place for everything and everthing in its place, so that items are easy to find.

-

1. Are items (materials, tools, equipment) that are in use stored away in designated areas? Are items stacked properly?

-

2. Are items (material, tools, equipment) that are not in use stored away in the proper place/designated areas? Are items stacked properly?

SHINE

-

Eliminate trash, dust and dirt from the work area. Clean to inspect, inspect to detect, detect to correct and correct to perfect.

-

1. Are work areas kept clean, uncluttered and free of waste? Is all debris and rubish picked up and placed in the proper bins?

-

2. Are storage areas (e.g. containers) kept clean and free of unnecessary items and debris?

-

3. Are rest areas (e.g. smoko rooms) clean and tidy?

-

4. Are sanitary facilities (e.g. portaloos) adequate and clean?

-

5. Is there an adequate number of waste bins, are they clean, clearly identified and maintained?

STANDARDISE

-

Set standard ways of doing things in place. Maintain the first three Ss and have awareness of improving workplace organisation. Management to explain why 5S is important. Detail the overall responsibilities of others to the 5S activities.

-

1. Are the 5S checklists used properly to identify cleaning frequencies/duties, improvements and needed repairs? Are the 5S sheets all up to date?

SUSTAIN

-

Monitor the other four steps, so good habits are kept up. The 5S discipline is embedded in the workplace so that it becomes a way of life. 5S is no longer an event but a regular routine (a way of life). Management to allocate the necessary time and resource to complete audits, checks and actions. Employees 5S roles to be clearly identified.

-

1. Are 5S action plans and cleaning rosters clearly displayed?

SUMMARY

-

Identified actions/problems during this audit?

-

Comments: