Information

-

Part No.

-

Part Name

-

Engineering Level

-

GD&T drawing no.

-

Program

-

Conducted on

-

Prepared by

-

Gage Builder Company Name

-

Contact person

-

Contact phone#

-

Location

-

Personnel

-

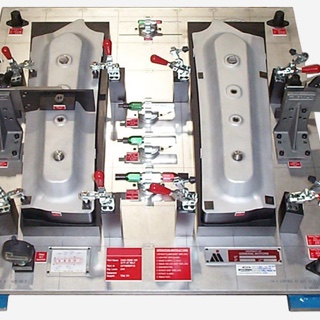

Take an overall view picture of the fixture or insert fixture drawing

-

Fixture Design or Fixture Build Buy Off

-

Is the fixture design to the current approved design engineering level?

-

Does component and/or assembly damun structure comform to GD&T?

-

Are all applicable datum locating points identified?

-

Is the part checked with and without clips (where applicable)?

-

Are standard and commercial items used, where possible, to minimize cost and simplify construction?

-

Are clamp pivot points in line with pressure points?

-

Is adequate clearance provided for component or assembly load and unload?

-

Do swing details clear other components?

-

Are all SPC and/or PQC checks accessible and follow GD&T coordinates?

-

Are details within perimeter of base when in opened position?

-

Are eye-bolt holes shown (handles for smaller gages)?

-

Will handling chains clear all details of fixture?

-

Do moving pins have lock-back features where necessary?

-

Title block, math data level and GD&T level, change column, etc., on design?

-

Are all operational safety issues addressed?

-

Have all responsible parties signed-off on the design? SQE, QE, Tooling Engineer, Process Engineer, Manufacturing Engineer, etc.

-

Safety 1st - use gloves and check for loose dowels, burrs, shims, sharp corners, etc

-

Does the gage build reflect current design engineering level?

-

All datums & checks exist per GD&T

-

All datums & checks are properly identified/stamped

-

All details are properly color coded, painted, or corrosion resistant coated and attached to the base?

-

Check for proper slip fit of locating pins, check pins, slide units, etc

-

Check for proper & safe function of swing units, templates, etc., (pinch points).

-

Check for proper fit & pivot align. of clamps to contact surface, (w/ mtl. thickness).

-

Is adequate clearance provided for part load and unload?

-

Check for proper function & clearance for SPC data collection units.

-

Are eye-bolt holes in base (handles for smaller gages)?

-

Will handling chains clear all details of fixture?

-

Do sliding pins move freely and have lock-back features where necessary?

-

Operator instructions are completed & attached to the fixture.

-

Functionality and R&R checks are completed & documented as per A.I.A.G.

Certification documentation is provided & verified for the below listed items.

-

The complete fixture certification, in its assembled condition.

-

Net datum surfaces, gage holes, tooling balls, and all GD&T features are included in the certification.

-

Sight checks, scribed lines, painted trim lines, (max/min tolerance bands), etc.

-

Certification & revision tags are properly filled out & attached to the fixture. GD&T and part math data level, part number and name, program, etc., on tags?

-

Shipping instructions are provided as required.

-

The fixture is constructed to agreed standards & construction tolerances. All responsible parties have signed off on build.