Information

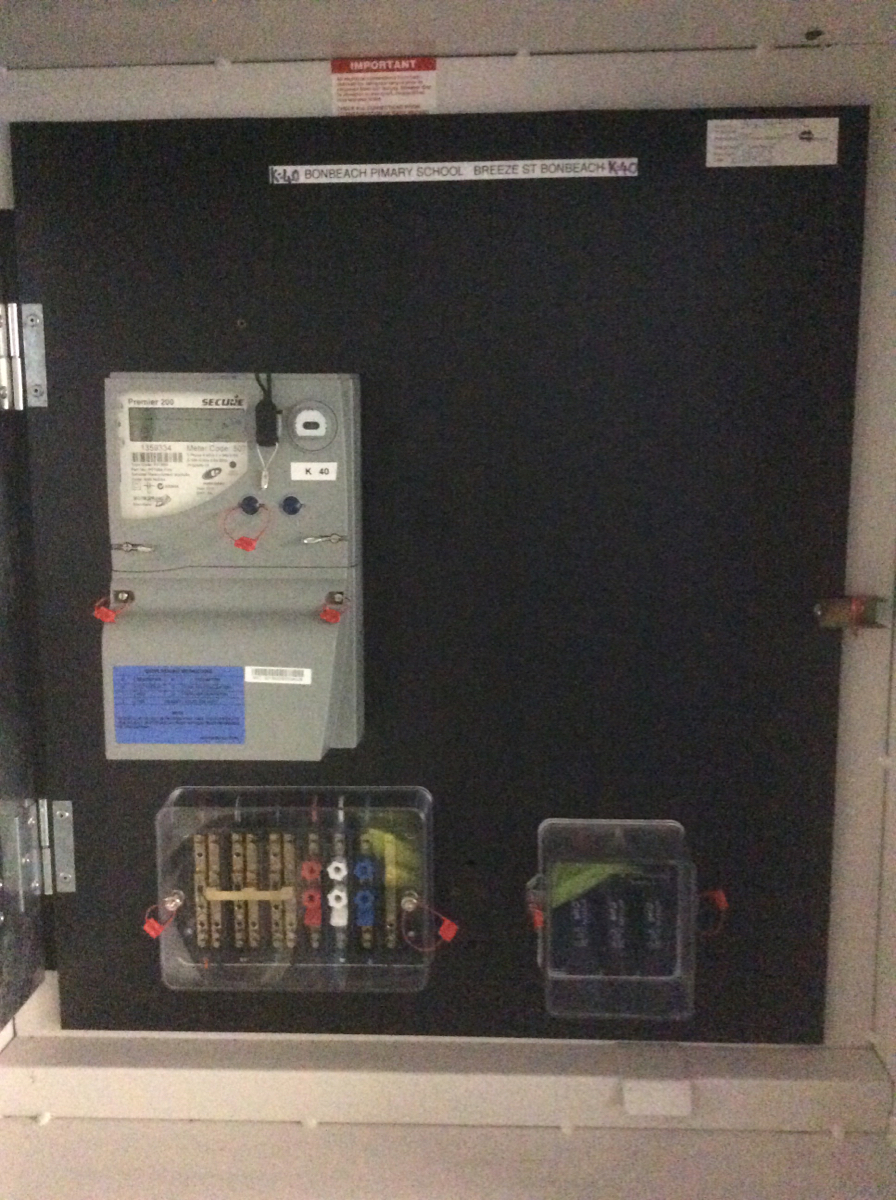

C.T. Metering post audit/ field audit

-

Document No.

-

Address

-

Conducted on

-

Prepared by

-

Seal Number

-

Number of non-conformances and observations

- WORK GROUP

-

NETWORK/CUSTOMER

Job safety assessment

-

Any hazards identified

PPE

-

Correct tools / equipment to perform task?

-

Is the correct PPE available to conduct task

-

Is a fire extinguisher available ?

-

Is a first aid kit available?

METERING ENCLOSURE

-

Is outdoor metering enclosure lockable with power industry padlock?

-

Is padlock provided a power industry padlock?

-

Is the C.T chamber pad-lockable or sealable ?

-

Is meter panel 900mm x 600mm or 600mm x 600mm?

-

Is the lower edge of the meter panel between 1m to 1.4m above the floor or ground level if situated independent/away from the CT chamber?

-

If located within a meter enclosure, a switchboard enclosure, switch rooms, cupboards or rooms set aside specifically for metering, is the lower edge meter panel no less than 700mm or greater than 1400mm above the floor or ground level?

-

Is the distance between the CT chamber and meter panel no more than 10m?

-

Is panel correctly hinged? No obstructions

-

Were all required sealing points found sealed? e.g. CT meter, test block, fuses, meter panel etc.

-

Sealing tong number legible?

-

Is all C.T. Metering equipment mounted correctly?

-

Has the meter screen been checked for fault codes and abnormality?

-

Have correct fixing screws been used on all metering equipment?

-

Is the communication port under the terminal cover connected correctly

-

Is phase rotation at meter verified correct?

-

Are all metering equipment screws checked for tightness<br>(Test block fuses meter terminals c.t terminals)

-

All wiring stripped to correct length and doubled into terminals?

-

Are potential fuses on meter panel 10A

-

Is meter panel labeled with correct address?

-

Is the correct constant label in place on front of meter (verified from C.T. Ratio)

-

If there are mains cables behind meter panel are they correctly shielded with metallic shrouding?

-

All metering cable properly secured behind meter panel and secured in C.T. Chamber with cable ties ?

-

Is metering enclosure earthed?

CT CHAMBER

-

CT chamber correctly labelled?

-

Is the CT chamber door correctly hinged?

-

Are potential fuses mounted correctly on top left/right or busbar mounted?

-

Are potentials fuses wired with 4mm SDI and connected to line side of C.T. Bus bar on the incoming supply

-

Are potential fuses in CT chamber rated 32 amps

-

Is the CT polarity correct - confirm red dot is facing the incoming supply?

-

Are C.T.Mounted at correct height the lowest mounted CT no lower than 500mm from ground and the highest C.T.no higher than 3 meters

-

Is there sufficient air gap between CTs and busbar?

-

Are CT terminals a maximum of 300mm deep from CT chamber door when closed?

-

Is enclosure a dedicated CT chamber only? (Ensure that no customer equipment is housed within CT chamber? i.e. MEN points, main switches etc.)

-

Is access to CTs free from protruding busbars?

-

Are CTs mounted after the SPD (Service Protection Device) but before the customer's main switch?

-

Are CTs in a multiple occupancy able to be independently isolated?

-

Is all CT wiring correct S1-S2 connections /red dot to incoming and potential fuses wired RWB from busbar

-

Is all wiring completed as per current Victorian SIRs?

CT METER INSTALLATION FIELD

-

Has enclosure been tested for de-energised

-

Has ct metering supply been isolated correctly

-

Have shorting links been installed

-

Have voltages and loads been measured

-

Have calculations been completed to network requiments

-

Have terminal screws on meter been checked with hand screwdriver

-

Has all equipment been sealed on completion

-

COMMENTS

-

Auditor Signature: