Information

-

Document No.

-

Audit Title

-

Client / Site

-

Conducted on

-

Prepared by

-

Location

-

Personnel

1.0 General Requirements

-

Confined Space CSE Registry #

-

Equipment Number

-

Location and Description

-

Description of tasks normally performed within the space

-

Reference to Rio Tinto C5 Confined Space Standard?

-

Scope

This standard is applicable to all Rio Tinto business units and managed operations, including new acquisitions, admin/corporate offices and research facilities located off site; during exploration, through all development phases and construction, operation to closure and - where applicable - for post closure management.

1.1 Confined space is an enclosed or partially enclosed space that:

a) has been identified as such in a risk assessment;

b) is not intended or designed primarily as place of work;

c) may have restricted entry and exit; and

d) may:

(i) have an atmosphere which contains potentially harmful levels of contaminant or explosive atmospheres;

(ii) not have a safe level of oxygen eg following a nitrogen purge; or

(iii) cause entrapment or engulfment.

1.2 Confined spaces may include, but are not limited to:

a) storage tanks, process vessels, boilers, pressure vessels, tank-like compartments that have only a manhole for entry, ceiling and floor spaces;

b) open-topped spaces such as pits, or grease traps, or excavations more than 1.5 metres deep;

c) pipes, pumps, sewers, shafts, ducts, drains, tunnels, cellars, basements and similar structures; and

d) abandoned workings and exploration audits.

1.3 Contaminant is any dust, fume, mist, vapour, gas, or other substance in liquid or solid form, the presence of which may be harmful to health and safety.

1.4 Entry to confined space occurs when a person’s whole body, upper body or head is within the confined space. However, this is not intended to prevent a person from inserting their hand or arm while holding a test instrument or probe into a confined space as part of the evaluation procedure provided that this procedure is duly authorised.

2. Identification

2.1 Confined spaces must be identified and permanent signage erected at the entry points denoting that a permit is required prior to entry. Where signage is impractical, for example with adits other means of highlighting the dangers need to be used.

3. Permit system

3.1 Entry to a confined space must only be allowed after a written approval, in the form of a permit, has been issued by a competent person, whom is authorised to issue such permits.

3.2 The permitting process must include the following elements:

a) a risk assessment, including the need for a competent person to assess such things as oxygen levels, contaminants, temperature extremes, and concentrations of flammable substances;

b) isolation procedures for contaminants and other energy sources;

c) the requirement for breathing apparatus;

d) the sign-in and sign-out of all persons entering the confined space;

e) display of the permit;

f) communication process and/or equipment between standby person and personnel within confined space;

g) safety specification of equipment to be taken into the confined space;

h) barricading;

i) rescue plan and equipment;

j) standby person; and

k) a completion procedure.

4. Other requirements

4.1 All persons required to work in a confined space, or to act as a standby person, must be trained, competent and tested.

4.2 Specific safe work procedures must be developed for work activities that are more hazardous when carried out in a confined space than elsewhere. These activities would include hot work (cutting and welding), chemical cleaning, steam cleaning, and abrasive blasting.

4.3 The standby person will have no other duties and is to be positioned outside the confined space entry point at all times while personnel are within the space.

4.4 Where the risk assessment has identified the need for ventilation, then this must be covered by a documented procedure. -

Assessment Team

Team Member

-

Name:

-

Position:

-

Does the space have a limited means for entry and exit?

-

Is the space not designed or intended for continuous human occupancy?

-

A "YES" answer to the above questions indicates that this is a CONFINED SPACE. Proceed through the following sections to determine the classification of confined space as either RED = High Hazard or GREEN = Low Hazard.

1.0 General Characteristics of the Space

-

1.1 What does the space usually contain?

-

What did the space last contain?

-

Is the product identified on the space? (Label or painted)

-

Is the equipment number (or identifier) clearly marked on the space?

-

1.2 Are there any hazards posed by contents or residue?

-

Is there a possibility of falling rocks or materials?

-

Is there a potential for entrapment or engulfment from solid materials?

-

Is there a potential for dusts, fumes, gases, or explosive vapors?

-

How will these hazards be controlled?

-

Is there a potential for corrosive injury or eye irritation to skin, eyes, or respiratory tract?

-

Detail hazard and list controls

-

Could the atmosphere be deficient or enriched with oxygen?

-

Detail hazard and list controls

-

1.3 Does the size, shape, or location of the space pose any unusual problems?

-

Detail hazards posed and list controls

-

1.4 How large is the entry way and where is it located?

-

Could its size, location, or configuration hinder escape, rescue, or provision of first aid?

-

1.5 Are interior surfaces potentially slippery?

-

Are there hazards created from sloped flooring or poor footing?

-

Detail hazard and list controls

-

1.6 Are there projections or objects that can cause cuts, bumps, and abrasions?

-

Are there any pinch points?

-

1.7 Are there any hazards outside the space that could pose a hazard to those within the space?<br><br>Consider moving equipment, pedestrian walkways, vehicles and mobile equipment, electrical equipment etc.

-

Detail hazard and list controls

-

1.8 Are there any potential hazards presented by local processes or operations in the area around the space?

-

Detail hazard and list controls

-

1.9 Is this space under construction, in commissioning, or newly built?

-

Has the Management of Change been completed and reviewed?

-

Have the equipment number labels and all wiring within the space, or piping feeding the space been verified as correct?

-

1.10 Has this space, the wiring for the space, or piping feeding the space been changed?

-

Have the drawings and equipment labels etc. been changed?

-

1.11 Have the products being pumped into the space been changed?

-

Have the labels and MSDS documents been changed?

-

Have the PPE requirements changed?

-

Is the space below grade where exhaust fumes or heavier than air gases could accumulate?

2.0 Atmospheric Testing

-

2.1 Are there any difficulties gas testing for the entire space prior to entry?

-

Detail difficulty and outline gas testing procedure:

-

What gas detection equipment will be used?

- Electronic Gas Detector

- Tube Detector

3.0 Physical Hazards

-

3.1 Are there any physical hazards within the space?<br>Electrical components<br>Mechanical Equipment<br>Nuclear Gauge<br>X-Ray<br>Pneumatic Operated Equipment<br>Other

-

What Type of physical hazard is present?

- Electrical

- Mechanical

- Nuclear

- X-Ray

- Pneumatic

- Other

-

Detail hazard and list controls

-

3.2 Are there external hazards outside the space that could harm workers within, entering, or exiting the space?

-

Detail hazard and list controls

-

3.3 What methods can be used to communicate with people inside the confined space?

- Radio

- Visual

- Other

-

Describe communication method

-

3.4 Are there products flowing into the space?

-

What type of product?

- Water

- Steam

- Air

- Kimberlite

- Flocculent

- Coagulant

- Sewage Effluent

- Slurry

- Glycol

- Treated Effluent

- Other

-

Describe product and list controls

-

MSDS Available?

-

3.5 Is access during an emergency difficult?

-

Detail difficulties

-

3.6 Is working at height an issue in the space?

-

What type of fall protection will be used?

- 6ft Lanyard

- 3ft lanyard

- Retractable Lanyard

- Other

-

What other type of fall protection system will be used?

-

3.7 Does the use of a lifeline cause an unmanageable hazard for the entrants?

-

Does the use of a harness cause an unmanageable hazard for the entrants?

-

Detail issue and list controls

-

3.8 Will temperature within the confined space affect the work?

-

Detail temperature issue and list controls

-

3.9 Is there a potential for wildlife?

-

Is there a potential for weather conditions to create hazards?

-

Is there a potential for seasonal conditions to create hazards?

-

Detail conditions and list controls

-

3.10 Could toxic metals be present in the confined space? (e.g. lead, cadmium, mercury)?

-

Detail potential toxic metals hazard and list controls

4.0 Potential Hazards Introduced from Work Activities

-

4.1 Will air contaminants be introduced during work activities

-

What type of air contaminants may be introduced?

- Welding Fumes

- Chemical Fumes

- Silica Dust

- Paint Fumes

- Abrasive Blasting

- Grinding Dust/Particulate

- Other

-

Detail hazard and list controls

-

Is an MSDS attached?

-

4.2 Will any portable equipment be used in the space that could introduce hazards?

-

What type of portable equipment will be used?

- Welding Cables

- Electrical Hand Tools

- Manual Hand Tools

- Lighting

- High Pressure Washing/Steaming

- Other

-

How will the tools be managed to eliminate hazards?

-

Is "intrinsically safe" lighting/electrical equipment required for this space?

-

Is ground fault circuit interrupter (GFCI) required for electrical equipment inside the space? (wet conditions)

-

Are non-sparking tools required?

-

4.3 Will any noise producing operations be performed?

-

Detail noise hazard and list controls

-

Will any tools introduce vibration hazards to the space?

-

Detail hazard and list controls

-

Are there any other hazards that require additional controls?

-

Detail hazard(s) and list controls

5.0 Classification

-

If the Assessment Team answered "YES" to ANY of the questions in Sections 1 through 4 - the space is considered a RED-HIGH HAZARD CONFINED SPACE.

-

Did the Assessment Team answer "YES" to any of the questions in Sections 1 through 4?

-

The space is classified as a RED- HIGH HAZARD CONFINED SPACE

Complete all pre-entry requirements and ensure hazard controls are in place and listed on the Confined Space Entry Permit. Entrants are required to complete Section A and B of the Confined Space Entry Permit. -

Did the Assessment Team answer "NO" to ALL of the questions in Sections 1 through 4 ?

-

This space is considered GREEN- LOW HAZARD CONFINED SPACE

IMPORTANT NOTE: This determination was made with consideration of "normal" work activities being conducted within the space. Entrants are required to conduct a thorough risk assessment prior to each task to determine whether the work being performed will introduce any hazard outside the scope of this assessment. If no additional hazards are identified during the pre-work JHA or other risk assessment, proceed with GREEN-LOW HAZARD CONFINED SPACE entry. For space determined to be LOW HAZARD - completion of Section A of the CONFINED SPACE ENTRY PERMIT is required.

If the planned work introduces a hazard not identified on this assessment - the space upgrades to a RED - HIGH HAZARD CONFINED SPACE and all pre-entry requirements for the space must be followed. Entrants are required to fill out sections A and B of the Confined Space Entry Permit -

It is the determination of this team the confined space covered by this document is considered:

-

List Assessment Team Members

Team Member

-

Name:

-

Position:

-

Signature:

6.0 Documentation

-

Is there an Isolation matrix attached?

-

Is there a Rescue Plan attached?

-

Is there a sample JHA for work activities normally performed in the space attached?

-

If the location or design of the space constitutes a hazard, attach drawings to the risk assessment.

-

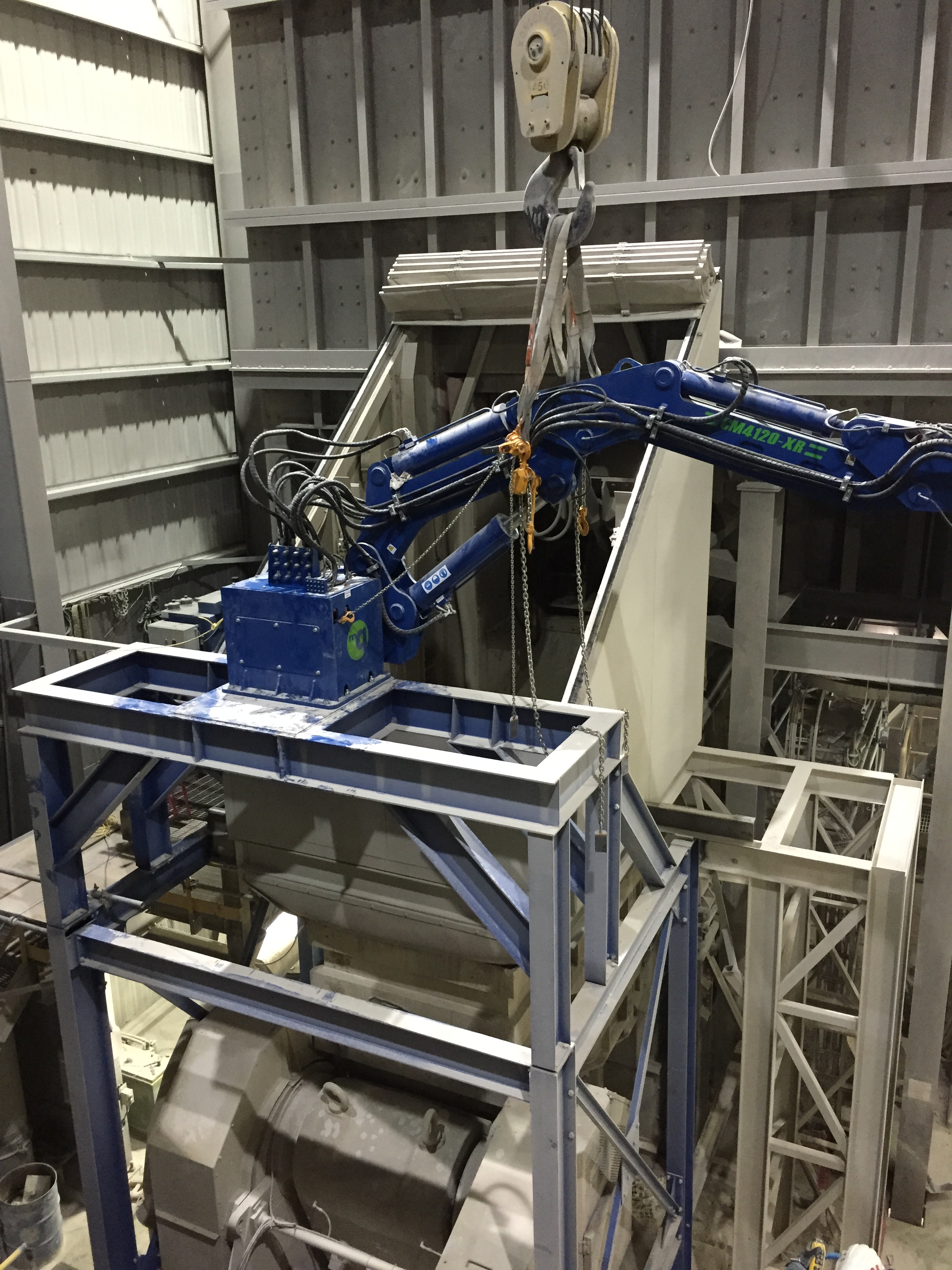

Photos of the space attached?