Title Page

-

Pit Number

-

Site

-

Personnel present

-

Location

-

Conducted on

-

Prepared by

Health and Safety

-

Compliant to Health and Safety as per UFF and contractors policy, OSH guidelines.

-

Have you signed onto site.

-

Take a photo of the Sign on sheet (ensure the correct focus)

-

Have you sighted the contractors JSA.

Pit Excavation / Placement

-

Pit has been positioned as per design rules.

-

Placement is correct - 3m away from poles, 5m from an intersection, safe from traffic where local conditions allow.

-

Excavation is correct, 150 - 200mm deeper than the pit, 300 - 400mm around the sides of the pit.

-

The bottom of the excavation conforms with the general ground slope.

-

Base foundation - a minimum of 100mm layer of rammed crusher dust free from foreign material.

-

Additional notes and comments.

Duct Entry

-

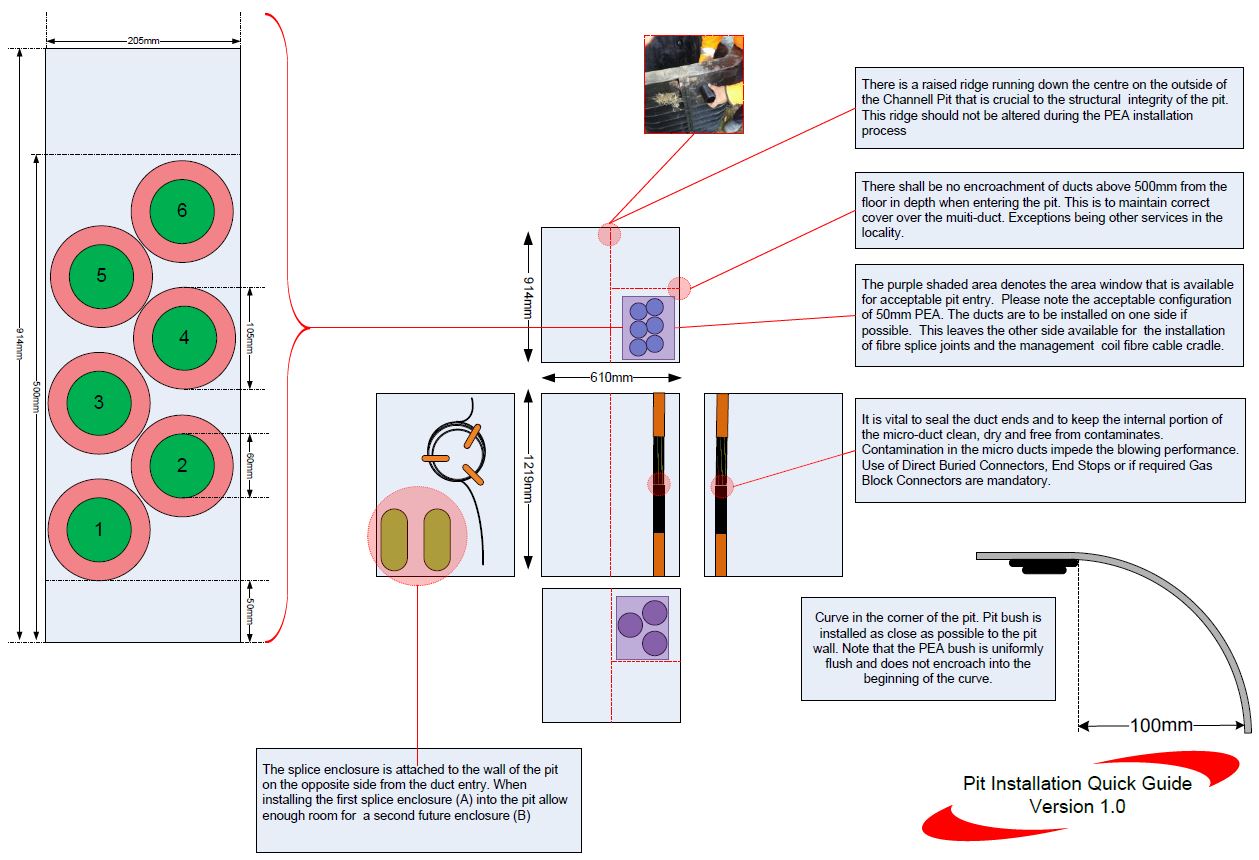

Pit layout

-

Multi-ducts bundles trench or drill shot gradually aligns with the entry points into the pit where local conditions allow.

-

Is the alignment correct.

-

Duct enters the narrowest end of the pit.

-

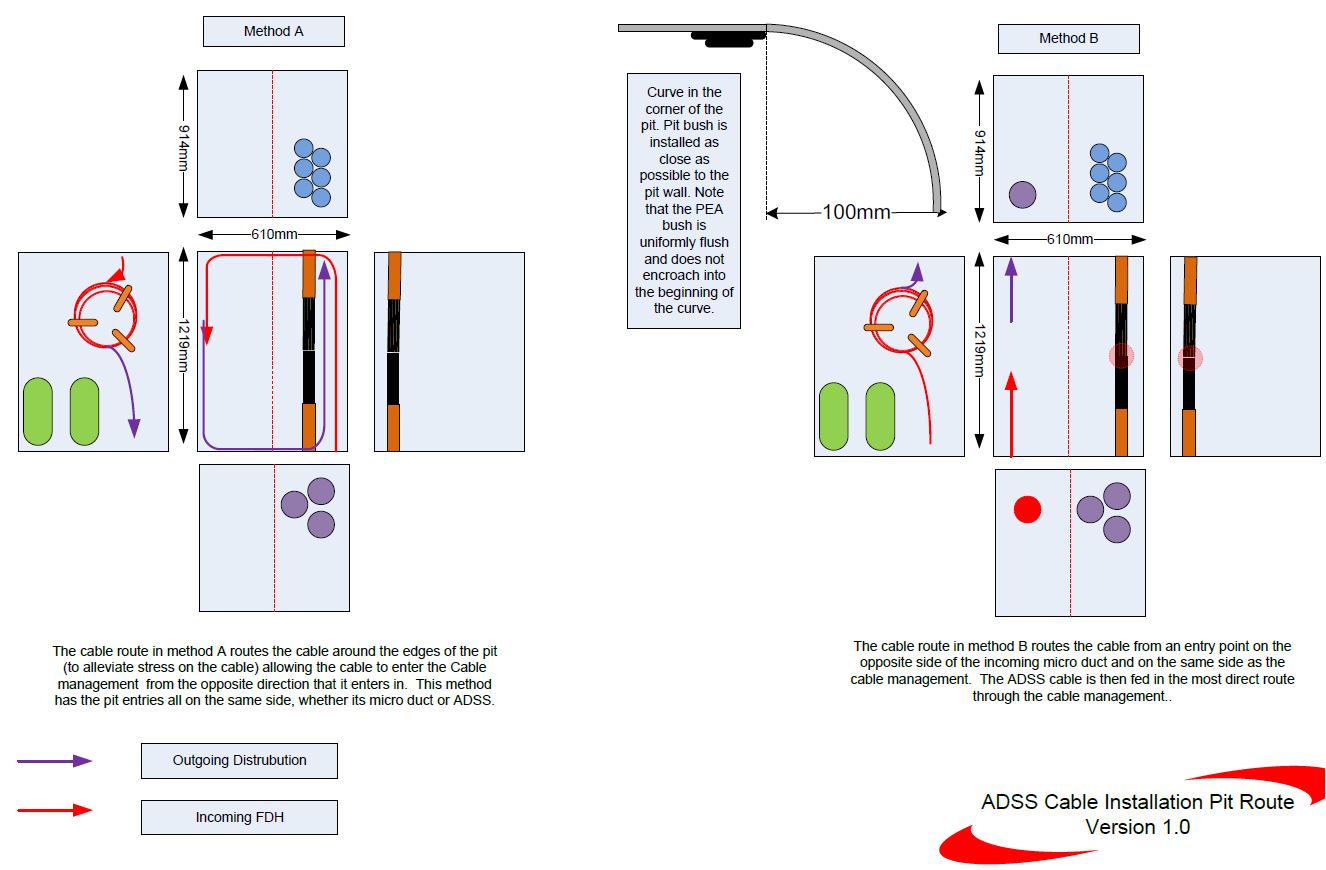

Pit internals

-

Photograph overview of the manhole internal to show entire pit layout.

-

Ducts installed on one side only to leave room for the joint enclosure and fibre loop management.

-

Ducts position into pit, a minimum of 50mm from the floor and 100mm from the pit wall is desirable.

-

Duct separation from other ducts, minimum of 25mm (to allow installation of the pit bush).

-

Duct hole size is correct - 20mm duct = 30mm hole, 50mm duct = 66mm hole, 100mm duct = 123mm hole.

-

100mm Starter Duct installed for multiple entries.

-

Starter duct fitted with pit bush.

-

Gaps around pit bush sealed with approved sealant where necessary.

-

All ducts sealed with ROCPAC. (7 way 14/10mm duct entry exempt in accordance with TU 028)

-

Additional Notes / Comments.

Reinstatement

-

Correct backfill and compaction used. Layer compaction of 200mm of earth.<br>Tap the side of the pit to listen for hollow sounds. If the surround is soil, probe the surround with the pit lifters to check ground density.

-

record issues observed. Take a photo of the ground penetration using the pit lifter.

-

Reinstatement around the pit correct and complete.

-

Photograph the overview of manhole surround from different angles.

-

Pit left clean and tidy inside.

-

Lid placed correctly locked and bung installed.

-

Is there any further information that should be recorded that has not been mentioned in the audit?

Labeling

-

Labelling Examples

Manhole Label - HW0004

Splice Enclosure -HW0004A, HW0004B

Feeder duct- HMW_402[0004A], HMW_402[0004Y],HMW_402[0004Z],HMW_402[0004X]

Feeder cable sheath into a splice enclosure - HMW102[0004A], HMW102[0004Y],HMW102[0004Z],HMW102[0004X]

Feeder cable sheath for a coil - HMW402[0004]

ADSS cable sheath - HW54763_A1[0004A] -

Is the manhole label present and in the correct format.

-

Photograph label if not captured above.

-

If transition tubes are used are the labels present and correct.

-

Close-up photograph of all labels (ensure focus is correct)

-

Multi-ducts present and correct.

-

Close-up photograph of all labels (ensure focus is correct)

-

If splice enclosure is present, is it labelled and in the correct format.

-

Close-up photograph of all labels (ensure focus is correct)

-

Fibre sheath labels present and in the correct format.

-

Close-up photograph of all labels (ensure focus is correct) .

-

Is there any further information that should be recorded that has not been mentioned in the audit?

-

Signature of auditor