Title Page

-

Customer Name

-

Site / Location

-

Inspection Date

-

Carried out by

-

Type of Inspection

-

Report Authored by

Inspection Summary

Inspection description

-

Details of the Site Inspection

-

Part / Product

-

Provide details on the site inspection, If a site layout is available please attach it here

-

People and responsbilities

-

Additional info, if any

Inspection Checklist

-

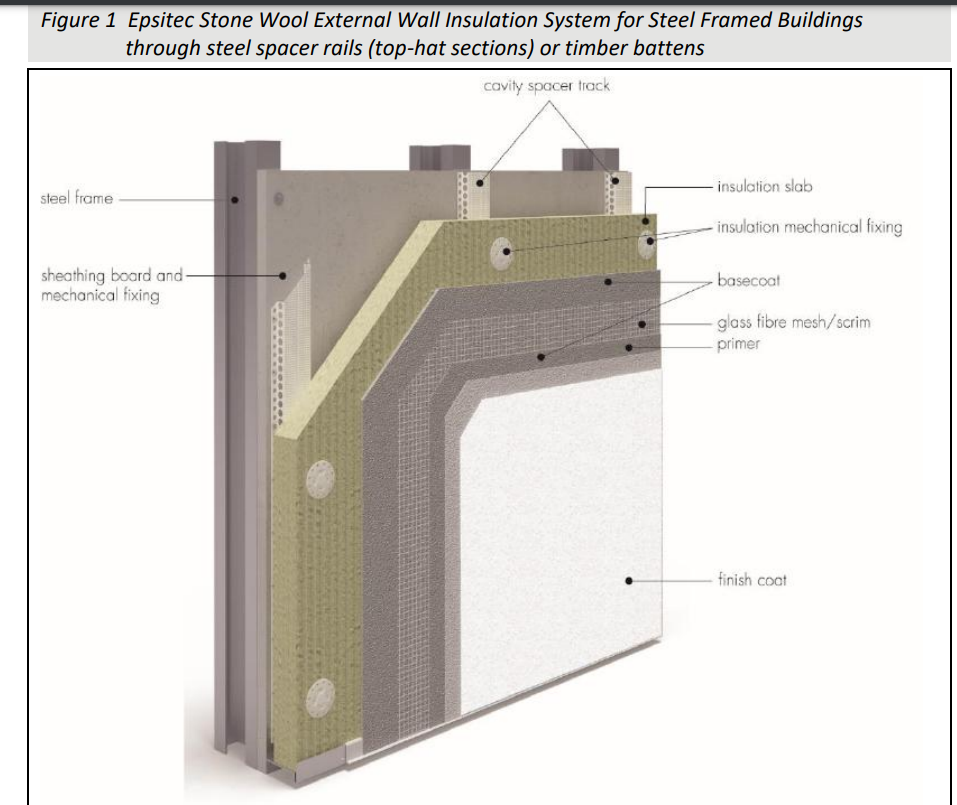

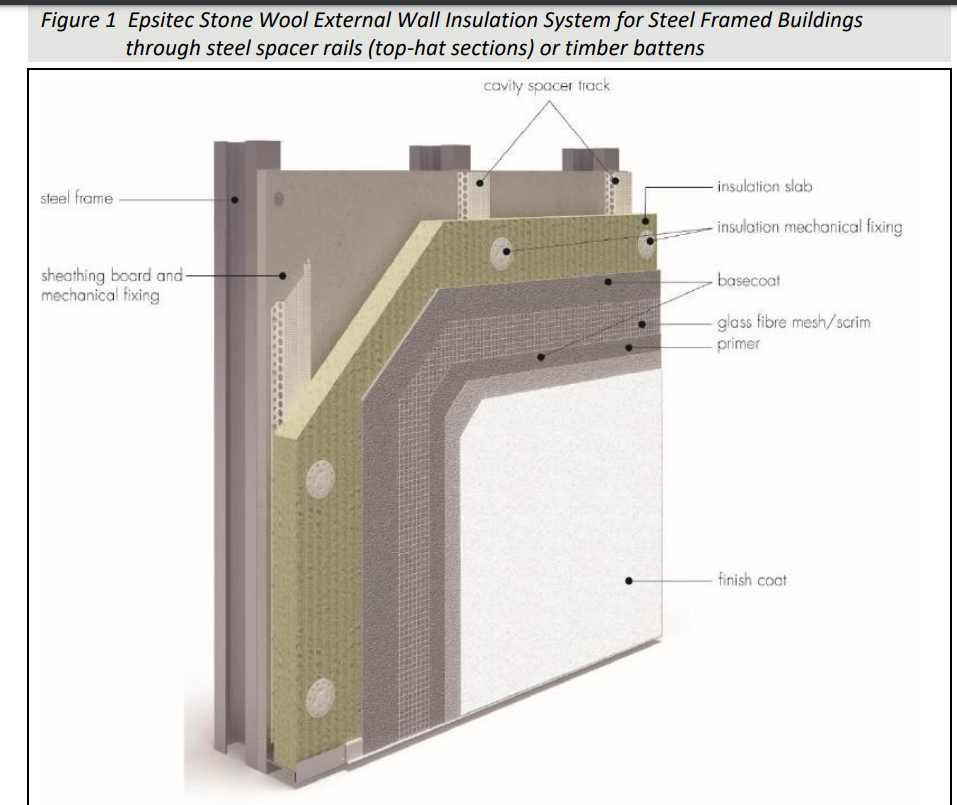

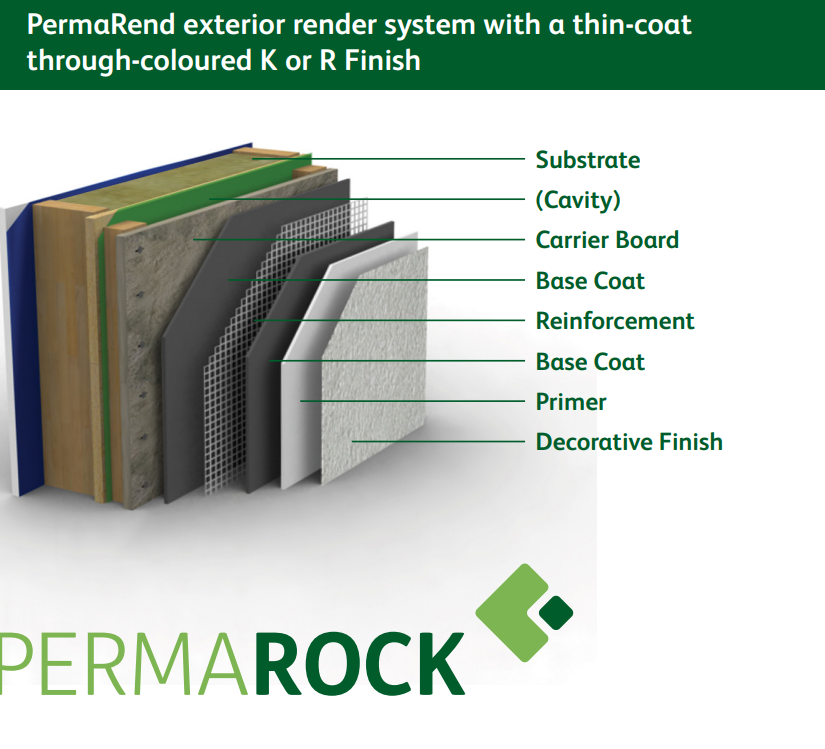

Is cavity width suitable for the installed cavity barriers, vertical full fill and air gap correct for horizontal cavity barriers?

-

Describe the Issue

-

Is the correct cavity barrier used for horizontal or vertical orientation?

-

Describe the Issue

-

Are adjoining ends of the cavity barriers tightly abutted?<br>The ends of the cavity barriers must be fitted tightly abutting to each other, at interfaces with perpendicular cavity barriers, and at junctions with vertical support rails, there can be no gaps

-

Describe the Issue

-

Are the cavity barriers undamaged?

-

Describe the Issue

-

Is the rear of the cavity barrier tight fitting to mounting substrate?

-

Describe the Issue

-

Are the correct fixings used to mount the cavity barrier, as detailed in the tables below?<br>

-

Describe the Issue

-

Are the correct fixings applied to the intumescing strip through the face? <br>This should not apply to the VFB Horizontal or the VFB Vertical when sized below 76mm, as fitting option 1 includes face fix screws, which secure the intumescent and the cavity barrier at the same time. <br><br>The VFB Horizontal and VFB Vertical, when sized over 75mm, are both supplied with factory fitted stainless steel screws, which secure the intumescent strip to the mineral wool, at 250mm centres and 125mm from cavity barrier ends.<br>Please note where lengths of cavity barrier are cut down and when vertical rails pass through the face of the VFB Horizontal intumescent strips and into the mineral wool, additional face fixings will be required, these should be provided at maximum 125mm from any cuts through the face of the cavity barrier or cavity barrier ends.<br>

-

Describe the Issue

-

Is there an avoidance of any blind spots that prevent the cavity barrier performing correctly?

-

Describe the Issue

-

-

Is the cavity barrier system free from potential weaknesses?<br><br>To eliminate the external angle, one of the VFB Horizontal cavity barriers must be over sailed past the corner, with an additional section of FF102 4mm intumescent strip applied to the bare end of the stone wool at the end of the cavity barrier, the intumescent must be mechanically fixed to the stone mineral wool using stainless steel wood screws @50mm long or 50-65mm stainless steel pigtails screws. One of the intumescent strips to the face of the VFB Horizontal must also extend 25mm into the rear of the horizontal carrier rails. The over sail cavity barrier must have a supporting bracket within 50mm of the external corner supporting construction.

-

Describe the Issue

-

Are all observations covered by the questions above?

-

Describe the Issue

Previous issues

-

Have any other issues been raised against this site previously?

-

What were the previous issues?

-

How were they addressed?

-

Are planned actions complete?

-

Were the actions effective in addressing the issue?

-

Have any opportunities for improvement been previously identified regarding this site?

-

Have actions been planned / implemented?

-

Were the actions effective?