Title Page

-

Project Number / Name or Site

-

Conducted on

-

Prepared by / Personnel undertaking the task

- Shannon Gore

- Kizito Zulu

- Hope Chimutasha

- Steve Siladi

- Corey Polkinghorne

-

Location

Take 5

-

1. Are you mentally and physically fit to perform the task?

-

If No, cease continuing Take 5 and contact your Supervisor

-

2. Are you authorised to undertake this task?

-

If No, cease continuing Take 5 and contact your Supervisor

-

3. Do you have the correct PPE for the task and is it in good working order?

-

If No, cease continuing Take 5 and contact your Supervisor or go and source correct PPE before proceeding

-

Do you require any specific training

-

Speak to your supervisor about Training

-

Do your require a Permit

-

Speak to your Supervisor about issuing a paper permit

-

Do you have appropriate emergency equipment for the task / location you are working in and are you aware of the following:

-

Contact your Supervisor and make yourself aware of the location of Emergency Equipment, Contact and Muster Point

Task Assessment

- Activity

-

Against each task list the hazards that could result in injury/damage when the task is performed by the worker

-

Select Activity

-

Select Changing tracks, cutting edges or teeth Hazards

-

Bites and Stings Controls

-

Crush Injury Controls

-

Cuts and Lacerations Controls

-

Equipment failure Controls

-

Exposure to Dusts, Chemicals or Fumes Controls

-

Eye Injury and/or Hearing Damage Controls

-

Falling Objects Controls

-

Heat Stress Controls

-

Inadequate Lighting Controls

-

Injuries from using faulty hand tools Controls

-

Isolated / Remote Work Controls

-

Manual Handling Controls

-

Plant on Plant / Person Controls

-

Public / Unauthorised Entry Controls

-

Slip, Trip, Fall Controls

-

Stored Energy Controls

-

Service / Structure Strike Controls

-

Weather Controls

-

Select General service, grease and oil change Hazards

-

Select Bites and Stings Controls

-

Burns Controls

-

Confined Space Controls

-

Crush Injury Controls

-

Cuts and Lacerations Controls

-

Damaged Lead or Burst Hose Controls

-

Electrocution Controls

-

Equipment failure Controls

-

Exposure to Dusts, Chemicals or Fumes Controls

-

Eye Injury and/or Hearing Damage Controls

-

Falling Objects Controls

-

Fire / Explosion Controls

-

Heat Stress Controls

-

Inadequate Lighting Controls

-

Injuries from faulty compressor, hoses or tools Controls

-

Injuries from using faulty hand tools Controls

-

Isolated / Remote Work Controls

-

Manual Handling Controls

-

Plant on Plant / Person Controls

-

Pressurised Air / Fluid Controls

-

Public / Unauthorised Entry Controls

-

Contact with Hazardous Chemicals Controls

-

Slip, Trip, Fall Controls

-

Oil / Chemical Spill Controls

-

Stored Energy Controls

-

Service / Structure Strike Controls

-

Site Communication Controls

-

Weather Controls

-

Select Grinding and Cutting Hazards

-

Bites and Stings Controls

-

Burns Controls

-

Confined Space Controls

-

Crush Injury Controls

-

Cuts and Lacerations Controls

-

Damaged Lead or Burst Hose Controls

-

Electrocution Controls

-

Equipment failure Controls

-

Exposure to Dusts, Chemicals or Fumes Controls

-

Eye Injury and/or Hearing Damage Controls

-

Falling Objects Controls

-

Fire / Explosion Controls

-

Heat Stress Controls

-

Inadequate Lighting Controls

-

Injuries from faulty compressor, hoses or tools Controls

-

Injuries from using faulty hand tools Controls

-

Grinder Kickback Controls

-

Isolated / Remote Work Controls

-

Manual Handling Controls

-

Plant on Plant / Person Controls

-

Public / Unauthorised Entry Controls

-

Contact with Hazardous Chemicals Controls

-

Slip, Trip, Fall Controls

-

Oil / Chemical Spill Controls

-

Stored Energy Controls

-

Service / Structure Strike Controls

-

Site Communication Controls

-

Weather Controls

-

Select Hydraulic hose / cyclinder repair Hazards

-

Burns Controls

-

Cuts and Lacerations Controls

-

Damaged Lead or Burst Hose Controls

-

Equipment failure Controls

-

Exposure to Dusts, Chemicals or Fumes Controls

-

Eye Injury and/or Hearing Damage Controls

-

Falling Objects Controls

-

Injuries from using faulty hand tools Controls

-

Isolated / Remote Work Controls

-

Manual Handling Controls

-

Pressurised Air / Fluid Controls

-

Contact with Hazardous Chemicals Controls

-

Slip, Trip, Fall Controls

-

Oil / Chemical Spill Controls

-

Stored Energy Controls

-

Select jacking and propping of mobile plant Hazards

-

Crush Injury Controls

-

Cuts and Lacerations Controls

-

Equipment failure Controls

-

Falling Objects Controls

-

Heat Stress Controls

-

Inadequate Lighting Controls

-

Injuries from using faulty hand tools Controls

-

Isolated / Remote Work Controls

-

Manual Handling Controls

-

Public / Unauthorised Entry Controls

-

Slip, Trip, Fall Controls

-

Stored Energy Controls

-

Service / Structure Strike Controls

-

Weather Controls

-

Select Plant washdown - cleaning and degreasing parts Hazards

-

Bites and Stings Controls

-

Burns Controls

-

Crush Injury Controls

-

Cuts and Lacerations Controls

-

Damaged Lead or Burst Hose Controls

-

Electrocution Controls

-

Equipment failure Controls

-

Eye Injury and/or Hearing Damage Controls

-

Falling Objects Controls

-

Heat Stress Controls

-

Inadequate Lighting Controls

-

Injuries from faulty compressor, hoses or tools Controls

-

Isolated / Remote Work Controls

-

Manual Handling Controls

-

Pressurised Air / Fluid Controls

-

Public / Unauthorised Entry Controls

-

Slip, Trip, Fall Controls

-

Oil / Chemical Spill Controls

-

Select Test and commission plant Hazards

-

Bites and Stings Controls

-

Burns Controls

-

Confined Space Controls

- Yes

- No

- N/A

-

Crush Injury Controls

-

Cuts and Lacerations Controls

-

Equipment failure Controls

-

Eye Injury and/or Hearing Damage Controls

-

Falling Objects Controls

-

Isolated / Remote Work Controls

-

Manual Handling Controls

-

Plant on Plant / Person Controls

-

Pressurised Air / Fluid Controls

-

Public / Unauthorised Entry Controls

-

Slip, Trip, Fall Controls

-

Oil / Chemical Spill Controls

-

Stored Energy Controls

-

Service / Structure Strike Controls

-

Site Communication Controls

-

Weather Controls

-

Select Tyre changing, inflation (compressed air) Hazards

-

Bites and Stings Controls

-

Burns Controls

-

Crush Injury Controls

-

Cuts and Lacerations Controls

-

Damaged Lead or Burst Hose Controls

-

Equipment failure Controls

-

Eye Injury and/or Hearing Damage Controls

-

Falling Objects Controls

-

Heat Stress Controls

-

Inadequate Lighting Controls

-

Injuries from faulty compressor, hoses or tools Controls

-

Injuries from using faulty hand tools Controls

-

Isolated / Remote Work Controls

-

Manual Handling Controls

-

Pressurised Air / Fluid Controls

-

Public / Unauthorised Entry Controls

-

Slip, Trip, Fall Controls

-

Stored Energy Controls

-

Select Use of crane, forklift or load handling equipment Hazards

-

Equipment failure Controls

-

Falling Objects Controls

-

Inadequate Lighting Controls

-

Isolated / Remote Work Controls

- Yes

- No

- N/A

-

Manual Handling Controls

-

Plant on Plant / Person Controls

-

Public / Unauthorised Entry Controls

-

Slip, Trip, Fall Controls

-

Stored Energy Controls

-

Service / Structure Strike Controls

-

Weather Controls

- Yes

- No

- N/A

-

Select Welding and Oxy cutting Hazards

-

Burns Controls

-

Confined Space Controls

-

Crush Injury Controls

-

Cuts and Lacerations Controls

-

Damaged Lead or Burst Hose Controls

-

Electrocution Controls

-

Equipment failure Controls

-

Exposure to Dusts, Chemicals or Fumes Controls

-

Eye Injury and/or Hearing Damage Controls

-

Falling Objects Controls

-

Fire / Explosion Controls

-

Heat Stress Controls

-

Inadequate Lighting Controls

-

Grinder Kickback Controls

-

Manual Handling Controls

-

Slip, Trip, Fall Controls

-

Any Additional Controls?

-

Photo (optional)

-

-

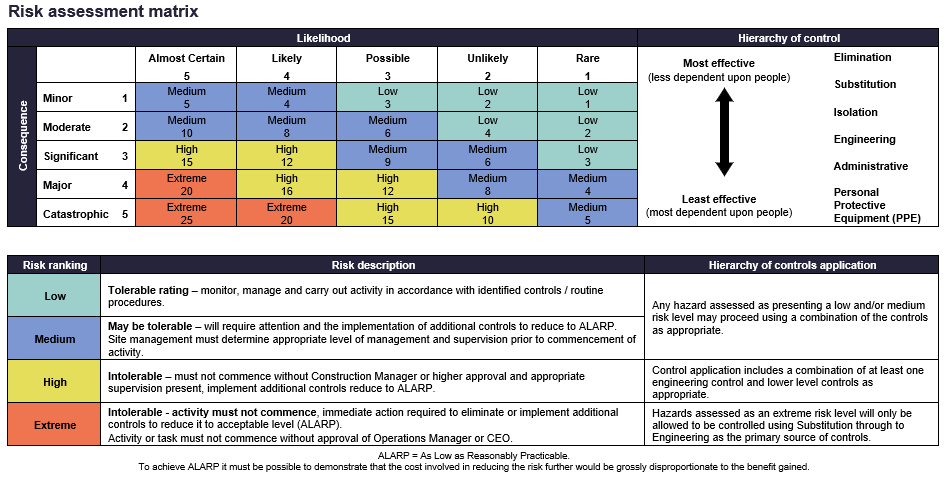

Risk Likelihood (chance of it happening)

-

Select Consequence

-

Intolerable - activity must not commence, immediate action required to eliminate or implement additional controls to reduce it to acceptable level (ALARP).

-

Activity or task must not commence without approval of Operations Manager or CEO.

-

Intolerable – must not commence without Construction Manager or higher approval and appropriate supervision present, implement additional controls reduce to ALARP.

-

May be tolerable – will require attention and the implementation of additional controls to reduce to ALARP.

-

Site management must determine appropriate level of management and supervision prior to commencement of activity.

-

Consequence

-

Intolerable - activity must not commence, immediate action required to eliminate or implement additional controls to reduce it to acceptable level (ALARP).

-

Activity or task must not commence without approval of Operations Manager or CEO.

-

Intolerable – must not commence without Construction Manager or higher approval and appropriate supervision present, implement additional controls reduce to ALARP.

-

May be tolerable – will require attention and the implementation of additional controls to reduce to ALARP.

-

Site management must determine appropriate level of management and supervision prior to commencement of activity.

-

Consequence

-

Intolerable – must not commence without Construction Manager or higher approval and appropriate supervision present, implement additional controls reduce to ALARP.

-

May be tolerable – will require attention and the implementation of additional controls to reduce to ALARP.

-

Site management must determine appropriate level of management and supervision prior to commencement of activity.

-

Tolerable rating – monitor, manage and carry out activity in accordance with identified controls / routine procedures.0-

-

Consequence

-

Intolerable – must not commence without Construction Manager or higher approval and appropriate supervision present, implement additional controls reduce to ALARP.

-

May be tolerable – will require attention and the implementation of additional controls to reduce to ALARP.

-

Site management must determine appropriate level of management and supervision prior to commencement of activity.

-

Tolerable rating – monitor, manage and carry out activity in accordance with identified controls / routine procedures.

-

Consequence

-

May be tolerable – will require attention and the implementation of additional controls to reduce to ALARP.

-

Site management must determine appropriate level of management and supervision prior to commencement of activity.

-

Tolerable rating – monitor, manage and carry out activity in accordance with identified controls / routine procedures.

Team Members

-

Select Name

- Shannon Gore

- Kizito Zulu

- Hope Chimutasha

- Steve Siladi

- Corey Polkinghorne

-

Shannon Gore

-

Kizito Zulu

-

Hope Chimutasha

-

Steve Siladi

-

Corey Polkinghorne

-

Is Supervisor available to review and sign off?

-

Supervisors Name and Signature

-

Supervisors Number

Approval

-

Date and time of approval

-

Approver's signature