Title Page

-

Conducted on

-

Prepared by

-

Location

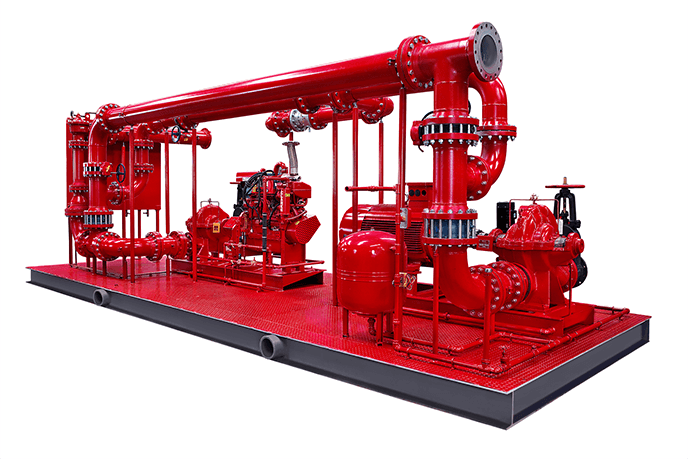

Setting up your pump system

-

Install, operate and maintain the fire pump and engine in accordance with the manufacturer’s written instructions.

-

The performance of a fire pump system relies on the design and performance of three elements. Is the fire pump, supply pipe and discharge pipe all operating correctly?

-

Is the the size of the supply pipe to the size of the pump’s inlet? i.e. use a 1.5 inch<br>diameter pipe for a 1.5 inch pump, or a 2 inch diameter pipe for a 2 inch pump.

-

Suction pipe pump systems

-

The integrity of the suction supply pipe and priming of the pump are critical

elements of a fire pump system.

If a non metallic suction supply pipe is subjected to radiant heat it will be

damaged, the pump will not deliver water, it will likely lose prime, run dry and fail.

This is a potential problem when drawing water from a water source where the

water level can drop e.g. a dam or swimming pool due to normal use or

evaporation during the summer. -

Have you checked all joints of a suction supply pipe are sealed and air tight? Note*<br>even a small air leak on the suction supply pipe will result in a very significant loss<br>of pump performance.

-

What is the angle of the supply pipe from the water source? Note* the pump should slope up evenly to enable pump priming to be achieved by allowing any trapped air to escape quickly through the pump.

-

Where is the water sourced from?

- River

- Dam

- Other

-

Is there an intake screen present and protecting the pump?

Priming

-

Is the water source above the level of the pump?

-

Simply open the supply valve.

If the pump needs to ‘suck up’ water from a lower level (say a dam that is partly

full) or an in-ground swimming pool, the pump case and the suction supply pipe

must to be completely filled i.e. primed. -

If the pump needs to ‘suck up’ water from a lower level (say a dam that is partly

full) or an in-ground swimming pool, the pump case and the suction supply pipe

must to be completely filled i.e. primed.

This can be achieved by providing a non-return valve (called a foot valve) at the

suction supply pipe inlet. Refer Images 4a and 4b -

4b

-

Setting up connections so a suction supply pipe and the fire pump’s case are

completely filled with water is very important. -

Is the suction pipe long?<br>

-

If the suction pipe is long it may also be necessary to provide a separate

connection to flood the suction supply pipe to enable the pump to prime. Refer

Image 3

It is important to test these measures before the bushfire season to prevent

problems being found if a pump start is attempted during a bushfire event.

Pump fuel tank capacity

-

Pumps fitted with a small fuel tank (about 3.3 litre) will likely run out of fuel before

they run out of water.

Having a container of fuel located too close to a pump adds to the risk. Refilling a

pump’s fuel tank during a fire event can be particularly hazardous. The engine

must be cool before the fuel is transferred.

In a real fire event the pump may need to run continuously for up to 6 hours or

more. -

How much fuel does your pump consume?

-

How much water is in your pump?

-

How much fuel is in your pump?

-

Fuel

-

Note*

Use a pouring spout to avoid spillage.

Protect fuel from radiant heat e.g. in a hole in the ground with concrete slab cover.

Petrol has an effective life of about 6 months.

Diesel has an effective life of about 12 months. -

What size is litres can is your fuel stored in?

-

20 litres is the max recommended size for fuel cans

-

Is your can ember proof?

-

In metres how far away is your can to your pump?

-

10 metres is the max recommended distance from your pump